3D Printed Hot Runner Nozzles, Pressure Pads Provide Reliable Temperature Handling

NPE2024: Witosa GmbH, through its distributor DMS, brings the Monolith hot runner nozzle and hardened steel Energy Blocker to the U.S., enabling the reduction in time, costs and improvements in product quality.

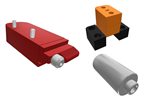

Witosa GmbH is making its U.S. debut at NPE by showcasing its Monolith hot runner nozzles and Energy Blocker printed pieces at the DMS Diemould Supply booth.

Since its launch in Germany in 2021, the Monolith nozzle has helped to advance the hot runner industry in Europe and East Asia. The one-piece, additively manufactured hot runner nozzle offers reductions in production time, costs and improvements in product quality, garnering interest from market leaders in the plastics processing industry, according to the company.

Featuring a distinctive honeycomb structure, the Monolith nozzle provides optimal insulation and a more uniform temperature profile compared to traditional multipart nozzles. This design flexibility enables precise customization to meet customer specifications, especially for technically demanding plastics. The Monolith hot runner nozzle product portfolio includes individual nozzles to system nozzles with open gating or valve gates in nozzle diameters 11, 16, 20, 22, 24 and 28 as well as freely selectable nozzle lengths.

Witosa is also introducing the Energy Blocker, additively manufactured pressure pads made of hardened steel that reduce heat dissipation from the manifold system into the mold, decreasing energy consumption by up to 52% compared to conventional systems with titanium pressure pads. The Energy Blocker’s hardened steel is said to make it significantly more pressure-resistant than conventional titanium backing plates. Because of its thermal insulation, users can also reduce the necessary cooling capacity of their mold while still ensuring the required heat dissipation. Its contact surface with the tool remains unchanged in size compared to conventional pressure pieces, resulting in increased tool rigidity and easier grinding if required. The hexagonal structure, already familiar via the Monolith hot runner nozzles, gives the Energy Blocker a high degree of rigidity. This innovation also contributes to reducing the carbon footprint of the production process.

Related Content

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

-

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.