Expansion of Online Moldmaking Catalog Streamlines Mold Component Search and Sourcing

DMS Components has launched a new part number lookup feature and 3D PDF facesheets to improve the online experience for design engineers and purchasing departments when searching for mold components.

DMS Components has expanded the capabilities of its online moldmaking catalog by adding a part number lookup feature and 3D PDF datasheets. Built by Cadenas PARTsolutions, these new capabilities are said to expand on the existing DMS moldmaking catalog, streamlining the process for design engineers to find and source mold components.

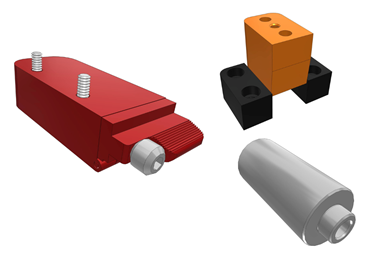

With more than 12,000 moldmaking components available, the DMS product catalog includes pins, ejectors, bushings and locating rings, as well as a wide selection of complementary products and supplies. By providing a part number lookup tool, DMS says it enables engineers to quickly find product data by entering a part number. The search results will provide a 3D product preview, engineering data and CAD models in more than 150 formats.

DMS Components strives to continuously improve its service and deliverables, and its online moldmaking catalog is no exception. Originally launched in 2009, the DMS 3D CAD catalog has been a valuable resource for design engineers at mold shops, as well as OEMs, according to the company. By providing interactive 3D PDF datasheets, DMS is expanding the online tool to benefit purchasing departments as well.

Related Content

-

Precision Micro Finishing Tools Supply Machine, Mold and Die Operations

Titan Tool Supply has made available 100+ products for immediate online order or shipment from stock, supporting advanced manufacturing requirements.

-

Decoding Reshoring: Motivations, Challenges and Technological Influences

Harry Moser, founder and president of the Reshoring Initiative, sits down for a Q&A on the motivations behind reshoring decisions, offering insights into economic, strategic and regulatory considerations.

-

Resilience and Reflections: Moldmaking in the Evolving Economic Landscape

As moldmakers navigate this complex year marked by fluctuating business activities, and approach the upcoming year with cautious optimism, three key considerations should guide their decisions.