3D Inspection Software is Dedicated to Flexible Scenarios Using Universal Portable Measuring Equipment

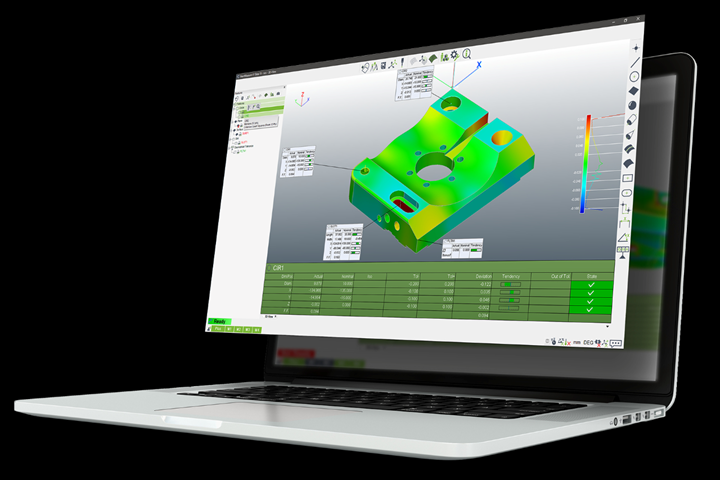

NextMeasure enables a solution for flexible, fast and efficient 3D quality control that is compatible with all sensors and portable measuring devices.

NextMeasure, a metrology software company, has launched a free universal 3D inspection software platform that is reported to be fast, reliable and compatible with all sensors and portable devices (e.g., scanners, measuring arms, laser trackers). The platform is ideal for analysis and inspection applications using measurement points and point clouds from a wide array of input formats and associated CAD files. Applications range from metal stamping, additive manufacturing (AM), prototypes, plastics, casting and other industries. Its primary uses are for design, manufacturing and quality control whenever and wherever a company needs it.

NextMeasure offers the core and inspection software free, with an instant download. The advanced metrology features and embedded capabilities included in NextMeasure Plus version are also currently available for a full year for no additional charge.

NextMeasure was created to overcome traditional measurement software, which is often tied to a company or measurement tool brand, and ensure absolute flexibility for fast, efficient 3D quality control. It can be downloaded for immediate use.

Using the free basic version, users are able to manipulate shape files to CAD and compare and analyze probe point, point cloud, alignment and GD&T. The drag-and-drop system is said to be effortless to navigate.

NextMeasure Plus adds the ability to connect directly with measurement devices. Portable device connection, acquisition/import of probe point, limited cloud filter, CAD transformation and leapfrog alignment are all part of this version. NextMeasure Plus advances cloud inspection with mesh edit and additional point cloud filter as well as the ability to assemble and retrieve point clouds automatically, and data output capability.

Once the software is downloaded, anyone on the team is able to access the point and click platform wherever they work. Multiple measurement platforms can be evaluated from a single user environment.

Related Content

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

-

Think Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.