Century Tool Invests in Cheto Machine for Deep-Hole Drilling With Milling

Seven-axis CNC strings together gundrill and milling programs, enhancing Century Tool’s moldmaking process.

Share

Read Next

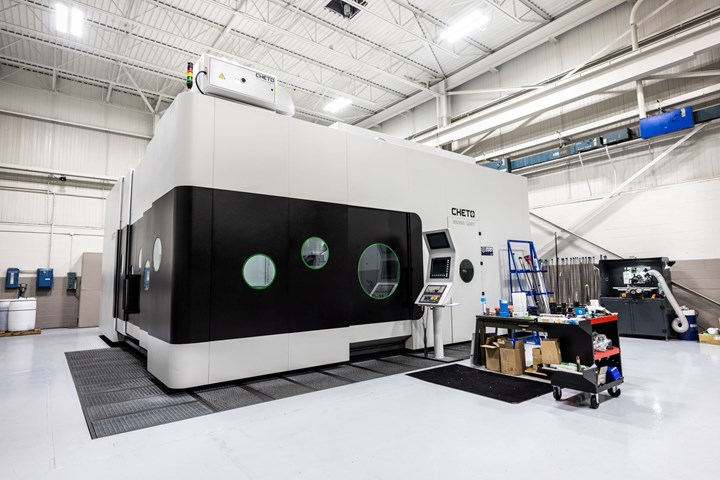

Century Toll is gaining productivity through the investment in a Cheto IXN 300 deep drilling with milling machine. Source | Century Tool and Cheto

Century Tool, a Tooling Tech Group company and a composites tooling specialist, has announced it has invested in a Cheto IXN 3000 — a seven-axis CNC deep-hole drilling and milling machine tool and one of only five in the U.S. Designed to enhance the moldmaking process, the Cheto IXN 3000 offers deep-hole gundrilling on one side with the capability of changing out the gundrill bit from a five-gun locker. On the milling side, the machine features a 50-gun locker for changing out cutting tools.

“We are excited to add this new capability to Century Tool,” says Lee Childers, Tooling Tech Group CEO. “The Cheto machine allows us to improve productivity by stringing together gundrill and milling programs, unattended, for up to 48 hours. And these machines are recognized for the steadiness and balance of their drills, all helping us better serve our customers.”

The Cheto IXN 3000 provides a spindle speed of 6,000 rpm and a 60,000-pound capacity. It enables Century Tool to drill as deep as 98 inches, as well as drilling more than three times faster than previous machines. Additionally, the system has the ability to monitor tool wear, helping to reduce tool breakage and increase uptime without operator intervention.

In addition to the Cheto IXN 3000, Century Tool has also invested in the company and the market with the recent purchase of Fidia five-axis and Toshiba three-axis machine tools.

Related Content

-

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.