Retrofitting and Updating CNC Controls Keeps Milling Capabilities on Cutting Edge

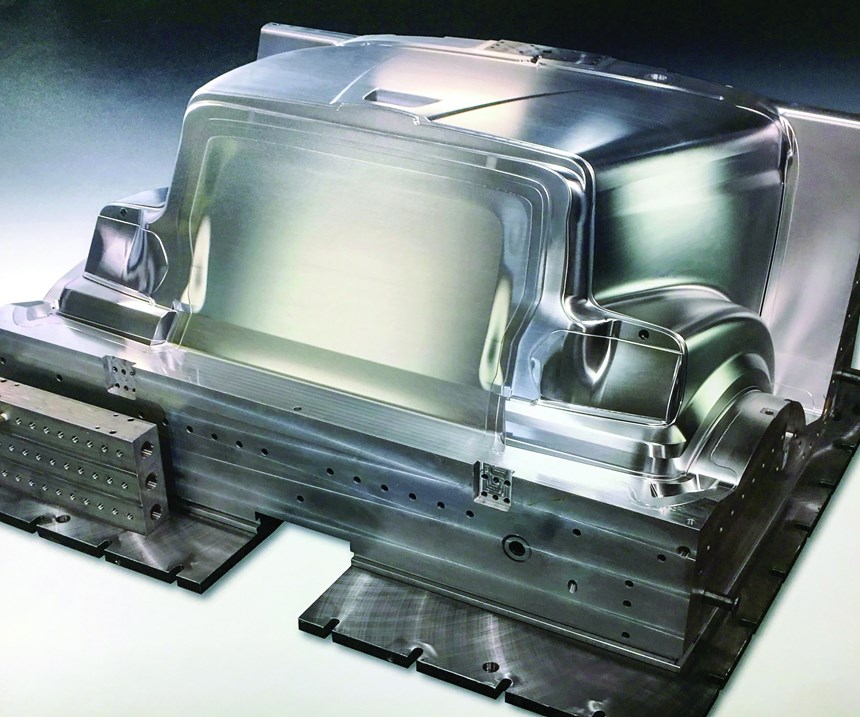

After struggling to achieve higher feed rates and accuracy for complex milling of large compression molds, Century Tool and Gage Company retrofitted Fidia CNC control systems onto existing machining centers.

In 1987, Century Tool and Gage Company (Fenton, Michigan) bought its first Heyligenstaedt vertical mill with the first Fidia CNC control system that was available in North America. Mickey Guckian, manufacturing manager of programming for Century Tool, was there. “I remember when we purchased the first Fidia control. It was installed on a two-spindle Heyligenstaedt vertical mill. I was running that machine at the time,” he says. “The new control had dual eight-inch floppy drives, which was unique back then, and it gave us the ability to greatly improve the feed rate for the complex milling routines we were running for the large compression molds we were manufacturing.”

According to Kevin Cummings, the company’s vice president, Century Tool was founded in 1974 and has experienced consistent growth over most of its history. This is due, in part, to expanding the manufacturing of composite compression molds to produce SMC, RIM and urethane parts for various sectors of the transportation industry. The company specializes in compression molded, exterior Class A and reinforcement panels for truck and trim applications. It also makes 75 percent of the exterior body panel molds. “We have become a major builder of molds and secondary tooling for the automotive, heavy truck, aerospace and personal watercraft industries,” Cummings says. With that growth came the company’s move to a new, 125,000-square-foot facility that is capable of handling 60-ton machine block sizes that are as wide as 100 inches and as long as 300 inches. The plant is equipped with four, five-axis CNC machining centers, seven heavy-duty vertical and horizontal machines, three CNC heavy-duty multi-spindle traveling column gundrills, 29 CAD/CAM workstations, and a try-out press facility with capacities of 500, 600, 1,500 and 3,000 tons.

“Before Fidia started developing a complete line of five-axis milling machines, they were building CNC controls,” Mickey Guckian says. “Dr. Giuseppe Morfino, Fidia CEO, was the young controls engineer that started it all, and he has been the guiding influence in the CNC machine control design that has played a significant role in making Century Tool and Gage a manufacturing and production success. All of our milling machines are CNC programmable and use Fidia controllers for high-level accuracy, dependability and productivity.”

Retrofitted for State-of-the-Art Productivity

Jorge Correa, Fidia’s vice president of sales in North America, says, “Century Tool is a great example of what can be done with control retrofits to bring existing CNC machine tools to state-of-the-art levels.” Since 1987, Century Tool has used Fidia’s CK10, CK20, Compac, C2, C20, a couple of Fidia’s tracing systems, and most recently, Fidia’s newest C40 controls. Today, the company has 25 Fidia CNC controls, but with ongoing control upgrades and the addition of new CNC machine tools, Correa says it has well over 30 controls. He says they have purchased one of Fidia’s GTFM.V3 five-axis gantry machines as well.

In concert with the Fidia controllers, Century Tool uses Tebis V4.OR2 software for five-axis machining. Tebis V4 software can translate all the software formats, including Catia, Iges, Parasolid, Step and Nx, to create the best tool paths. It is the only software that can generate the tool path right off the surface. “It creates a greater amount of contact points, producing a more accurate part,” Guckian says.

Each of Century Tool’s CNC mills with the Fidia controls has automatic scaling features for each axis to translate CNC program parameters to fit the size of the workpiece and is connected, via ethernet, to the company’s programming computers for continuous transfer of CAD data. “This allows Century Tool to have the flexibility to expand the customer’s product design ideas, but also the ability to communicate in direct language formats,” Guckian says.

Retrofitted for Peace of Mind

Century Tool first encountered the new Fidia C40 Vision Control with its ViMill anti-collision software at IMTS 2014 and purchased the hardware and software components on a new Fidia GTFM five-axis milling machine right after the show. “What immediately impressed us about the C40 control is that it can handle very large data programs of 50 megabytes or more. Some mold surfaces are very complex and rich with detail. The Fidia controls can handle the data file sizes and still provide smooth and accurate finishes,” Guckian says. “At Century Tool, we also work on older compression molds that need to be re-worked with new engineering changes, which typically involves more blending of surface cuts. Excellent finish is a must for these types of projects. The Fidia controls have vastly improved this capability by increasing their look-ahead from 300 to 1,000 lines of point data, which gives the machine the capability to prepare itself better for the upcoming shapes it is about to create.”

For example, high machining speed and excellent surface finish is the desire of any mold shop using five-axis milling machines, and Guckian says that Century Tool attains excellent surface finish because of its ability to precisely control acceleration and deceleration. According to Correa, the C40 Vision Control’s multi-processor architecture manages user-interface, axis and tool path control, and ViMill real-time anti-collision software, which together work to produce the fast machining speeds and high-quality surface finishes. “It’s one thing to have fast processors, but you need very good communication software parameters to enable the drives and motors to communicate at these fast feed rates,” he says. “The Fidia control allows the machine to be fine-tuned for various dynamics, such as part weight, length and width, spindle speeds, rigidity—basically anything needed to achieve a very accurate finish in a shorter period of time.”

According to Guckian, Fidia’s ViMill software in the C40 Vision Control is extremely user-friendly, and it is very easy to train operators to use it. Its real-time, anti-collision feature provides very safe milling conditions for very complex mold machining by projecting 1,000 lines of code. That projection prevents any collision between the tool, the machine and the workpiece in real time during milling operations, and in both jog- and part-program execution mode. “The operator has the ability to use the handwheel on-the-fly for the X-Y-Z-A-C axes and normal-to-vector compound angles. We are not aware of any other control that has that feature,” he says.

Retrofitted for Optimum Accuracy

Typically, Fidia GTFM five-axis milling machines are outfitted with the Head Measuring System (HMS), which has greatly reduced the time it takes for Century Tool machinists to verify the accuracy of heads and roto-tilting tables. The HMS reduces that time from one day to less than an hour. “The HMS is a high-precision alternative to the traditional dial gages and is a very important facet of the five-axis cutting technology. The HMS keeps the five-axis head as accurate as possible, usually within 10 microns. This is vitally important when the mold is being machined unattended, which is usually at night,” Correa says. He adds, “The Fidia measurement software within the control manages the mold cutting. The software is equipped with three high-precision displacement measuring devices and allocated to measure 3D volumetric errors. By processing incoming data in real time, the software can check and compensate for limited geometric error, avoiding costly corrective mechanical interventions.” Guckian says it lets Century Tool save the desired settings and ‘stick with what was set,’ all within 5 microns. “The machine ran for eight months without having to change calibration parameters on the head,” he says.

A laser maintains the Rotation Tool Center Point (RTCP) function, which is another feature that the Fidia control software manages. The laser will accurately measure the length and diameter of the cutter at each tool change, which provides for a continuously accurate height setting on the mold from cutter to cutter.

Having multi-processor architecture in the control allows for updates and empowers the system through the partial or total replacement of the PC (memory, hard discs, adapters, etc.) without modifying other computer components. The GTFM machine has three central processing units. As a result, it is possible to keep the CNC constantly up-to-date with the most powerful hardware and software developments.

For example, Fidia’s Velocity Five upgrade is a new, multi-axis trajectory control technology with a dynamic-selectable set of roughing and finishing parameters. These parameters allow the user to execute fast and highly accurate, high-quality milling by improving the acceleration control techniques. Century Tool estimates the Velocity Five upgrade can reduce finish milling time on 3D profiles between 15 and 20 percent and roughing between 30 and 40 percent. The machined surface quality shows significant improvement and faster execution of machining small radii areas.

“We are adding another Velocity Five upgrade to another finish milling machine this year, and we are adding two or three more C40 Vision Controls with ViMill collision control to additional machines,” Guckian says. “We also have a new FPT Ronin horizontal mill on order that we will equip with the Fidia C40 Vision Control with the ViMill anti-collision software.”

Related Content

Three Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MorePredictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreTips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)