How to Make the Switch from Negative to Positive Tool Offsets

Tips for changing from traditional touch-off methods to an offline presetter to optimize spindle times and reduce errors.

The traditional touch-off method for tool presetting, which involves touching off on a workpiece or fixture using a touch probe, has several drawbacks. It is susceptible to human error, such as the operator not accounting for the thickness of paper or fat fingering the measurements in the control. The chances for error can still exist with the use of a presetter. Each negative offset is relative to the machine it was taken in and using an offline presetter with negative offsets forces multiple comps in the presetter software.

Presetting with positive values comes with quite a list of benefits.

The results are typically negative Z-axis readouts from the control and valid only for that specific tool in that machine. If a fixture is moved or replaced for a new job, the associated tools need to be touched off again. This setup time could be reduced had all the tools been preset with positive offsets and the precious spindle time could be used instead for making chips.

Presetting with positive values comes with quite a list of benefits. For example, the offset is the true length of the tool relative to gage line; moving or changing fixtures does not require the operator to remeasure tools; and the tools can be used interchangeably between different machines without remeasuring (but be sure to calibrate machines to the presetter). Positive values are easier to think about and are more intuitive to work with and calculate.

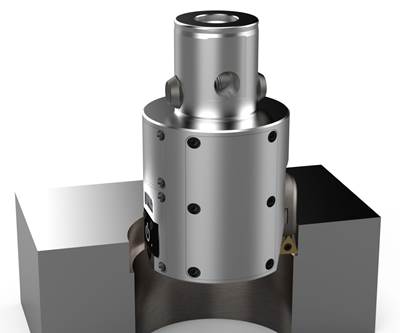

Further benefits of using a presetter over touch probes include the fact that presetters are not only capable of full tool inspection, but also measuring tool length offsets while machines are simultaneously running and making chips. There is no need to run test cuts in most situations with presetters, and it is significantly easier to set bore diameters. Touch probes cannot measure tool runout like a presetter can.

Touch probes cannot measure tool runout like a presetter can.

Presetters can measure extra features, like tool stick-out, radii and angles, and they can verify other forms of tool geometry and theoretical points. An additional benefit, reducing runout in tools outside the machine center leads to increased tool life, better part quality and less scrap—all things shop owners and manufacturers covet.

Presetters allow for viewing the tool with an inspection light. This 45x magnification camera can detect wear and defects, such as worn inserts, chipped carbide and built-up edges invisible to the naked eye. They can also digitize setup sheets with tool management capabilities by creating job- or part-specific setup lists with tool information, tolerancing, and setup instruction. These abilities further mitigate operator mistakes during tool assembly.

CNC Tool Presetters

CNC tool presetters can perform multiple measurements automatically while an operator prepares the next tool for measure. This innovative process increases efficiency while decreasing setup time. Many presetters are capable of post processing, allowing for the measured height offsets to be sent directly into the control. This way of direct downloading of offsets decreases setup time and helps to eliminate dreaded “fat finger” errors. Finally, the entire shop can be supported from a single, centrally located presetter due to using multiple formats in the presetter post processor.

Overall, making the switch from negative to positive offsets has never been easier for shops. Many modern controls are already set for positive tool length offsets, which is oftentimes as easy as a parameter change. Calibrating all machines is simple with the use of a probe or master cylinder with a pre-defined height. A suggestion is to create a macro to compensate the length of travel from gage line to the table or fixture to then accept oncoming positive values.

About the Author

Patrick Cratty

Patrick Cratty is the Assistant Product Manager TMS at BIG KAISER Precision Tooling Inc. (Hoffman Estates, IL). Patrick studied at the College of Lake County in Grayslake, Illinois. Since joining the BIG KAISER team, Patrick has spent his time visiting customers to find the right solutions for their tool measurement and management needs. He also installs new presetters and repairs existing machines. He works closely with Speroni in Italy for ongoing product training. Patrick can be reached at (224) 770-2910 or patrick.cratty@us.bigkaiser.com.

Related Content

MMT Chats: Westfall Technik Talks Runnerless Micro Molds and More

Westfall Technik sits down with MMT Editorial Director Christina Fuges to discuss their new micro hot runner technology, the closeness of the moldmaking community and the importance of integration. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreHow Moldmakers Impact New Product Development

Dynamic Tool Corp. discusses the mold builder’s role in defining injection molds to support new product development with MMT Editorial Director Christina Fuges.

Read MoreMMT Chats: The Rise of Tooling Digitalization

MoldMaking Technology Editorial Director Christina Fuges chats with Bob Vancoillie with the Consumer Division of Johnson & Johnson about OEM corporate initiatives for digitizing tooling.

Read MoreVIDEO: Insights and Best Practices for Mold Care

Slide Products President Michael Muth shares the products and practices he believes have helped the moldmaking industry the most when it comes to caring for molds.

Read MoreRead Next

Tips for Mitigating Chatter and Vibration

A review of the problems of machine vibration and the strategies and tooling systems that that can stop them.

Read MoreA Review of High-Productivity Workholding Solutions

Insights on workpiece stabilization and non-traditional fixturing with an emphasis on modern-day solutions.

Read MoreClosing the Loop on Automatic Boring

Some thoughts on the next step in automated tooling adjustment systems for boring mills.

Read More