Closing the Loop on Automatic Boring

Some thoughts on the next step in automated tooling adjustment systems for boring mills.

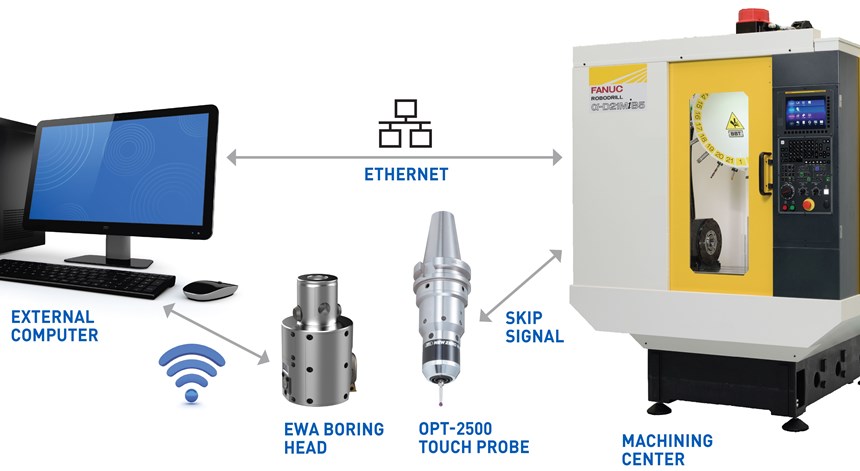

There are several factors coming together simultaneously to make closed-loop automated tooling adjustment systems possible. Data handling has improved with faster communication of the vast amounts of data being collected by machines, not humans. Better sensors and controllers also played a role, since they are now smaller, more compact and more efficient. The emergence of AI, or artificial intelligence, allows for machine learning from other machines and less reliance on people.

As far as human-machine interactions go, now workers can have the entire manufacturing floor simulated, re-routing flow to maintain productivity. This also means better transfer of data to the physical realm—think 3D printing for prototyping.

Automatic fine boring offers a plethora of benefits.

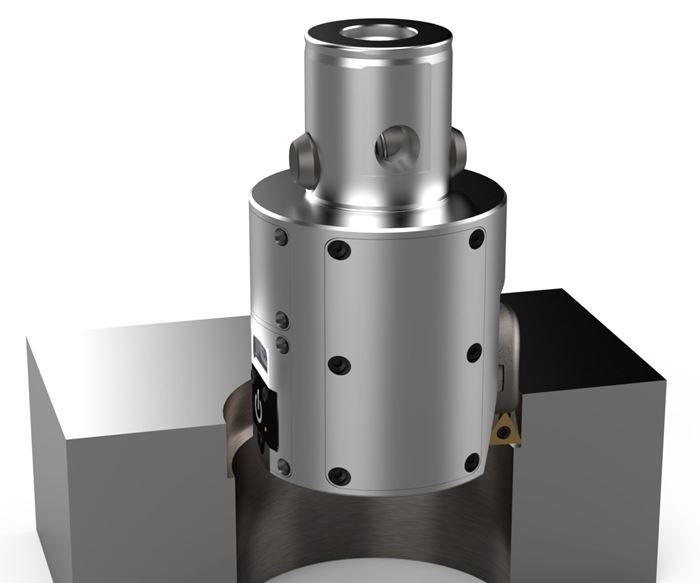

Automatic boring is not a completely new idea; it builds on already existing technology. For example, Big Kaiser offers an app through which the EWE boring head can communicate, helping operators manually adjust the tool more accurately and repeatedly. Other companies may offer similar apps. However, there is still potential for errors while entering information into the app, and a manual step is still required.

Why would one want to remove the manual adjustment step? There are several reasons to remove it: improve cycle times, reduce human error, increase operator safety, and make room for automated or unmanned operations. Ultimately, the goal is to implement automatically adjustable boring tools and push productivity forward.

As with the manual step, there are obstacles, as well as logistical questions, facing automatic cycling, starting with the obvious: how is it going to be possible? How much back and forth communication is necessary? How many components are needed? How limited is the adjustment range? Working with an experienced, reputable supplier can help answer these questions.

Some important factors to keep in mind when considering implementation of automatic boring:

- The best-case application condition would be high-volume precision bores with newer / high-end equipment. It doesn’t make up for equipment that isn’t well-maintained; to work properly, cleanliness and proper maintenance are still key with this technology.

- This technology does not replace operators that can’t be trusted to make corrections. Rather, it will require highly skilled people to handle issues.

- The technology also requires the use of good boring practices in order to give repeatable results.

Automatic fine boring offers a plethora of benefits. For one, fully automated machining cycles means no more pauses in machine cycle for manual adjustments, plus it makes unattended machining possible. The chance of human error is also reduced. Improved efficiency and mitigated cycle times are additional benefits. The automatic boring tool adjusts for potential wear based on machine measurements, and under-sized bores are also prevented.

Ultimately, the goal is to implement automatically adjustable boring tools and push productivity forward.

There are still a few manual steps needed for the automatic boring process, starting with setting the initial diameter of boring tool and changing of both tool configuration and cutting inserts. Next is loading the boring tool into the machining center, then multiple checks to ensure that the machine is working properly.

As automatic boring makes its way into the industry, it opens the door for exciting future possibilities: tools talking with tools, additional opportunities to stay connected and advancements in tool management software. It also raises some poignant questions, like what other information could we deliver to/from our boring tool? How will cutting time recording, tool clamping and unclamping temperature and vibration analysis be improved?

It’s clear that automatic boring is bringing change and innovation to machining. It brings solutions and valuable insight to efficiency and measurement.

About the Authors

Matt Tegelman

Matt Tegelman is the Applications Manager & Product Manager Kaiser at BIG KAISER Precision Tooling Inc. (Hoffman Estates, IL). Matt Tegelman earned a Bachelor of Science degree in Mechanical Engineering from the University of Wisconsin in Milwaukee. Since joining the BIG KAISER team, Matt has spent extensive time visiting customers to implement new tools and troubleshoot existing applications. He also attends regular technical meetings in Switzerland for ongoing product development and has completed training on repair/assembly of boring heads. Matt can be reached at (224) 770-2914 or matt.tegelman@us.bigkaiser.com.

Nick Jew

Nick Jew is the Research and Development Engineer at BIG KAISER Precision Tooling Inc. (Hoffman Estates, IL). Nick Jew earned a Bachelor of Science in Electrical Engineering from the University of Illinois at Urbana-Champaign. Since joining the BIG KAISER team, Nick has traveled to BIG KAISER in Switzerland for new product technical development and specializes in machine integration of tools. Nick can be reached at (224) 770-2946 or nick.jew@us.bigkaiser.com.

Related Content

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreRead Next

Tips for Mitigating Chatter and Vibration

A review of the problems of machine vibration and the strategies and tooling systems that that can stop them.

Read MoreA Review of High-Productivity Workholding Solutions

Insights on workpiece stabilization and non-traditional fixturing with an emphasis on modern-day solutions.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More