A Review of High-Productivity Workholding Solutions

Insights on workpiece stabilization and non-traditional fixturing with an emphasis on modern-day solutions.

It’s no secret that shops need to be flexible to keep up with today’s marketplace, all while maintaining high part quality. Shops are no longer only making one part at a time or one type of part—their customers expect a more divergent product mix. A new type of request, or even machine type, can come at any time, and the fixturing process needs to play a part in the flexibility required to keep up.

Top shops, as denoted by Gardner Business Media’s annual survey, take advantage of every bit of new technology and put it to good use. The biggest difference between a top shop and a standard shop is unattended machining—allowing minimal interruption and reduced operator involvement. In many of these environments, the loading of parts and fixtures is simplified—the operator only having to load raw material or having the ability to set several workpieces at once.

Four- and five-axis positioning also is growing in popularity among the most successful shops. It allows a workpiece to rotate multiple times, thus gaining access to all sides of the workpiece without an operator rotating it manually.

Having both horizontal turning centers and horizontal machining centers, equipped with CNC lathes, is an effective mix. The highest level of production is reached because these machining centers able to perform multiple operations on a workpiece with minimal operator involvement.

It’s clear, versatile workholding technology offers various benefits. They adjust to these emerging machining solutions to eliminate the risk of operators working inside the machine, spindle uptime is higher, and it takes advantage of a cell’s capability to run unattended.

Comparing Various Workholding Solutions

Those who are looking for alternative fixtures should consider a standard vise that works day-in and day-out. It is tried and true, flexible, cheap, and great for one-off parts or prototypes. But vises generally aren’t intended to be moved, operator variations in speed and repeatability may be an issue and setups can be cumbersome for odd shapes and part surfaces, so it’s important to know when to step away from using only a vise. Be advised—any vise can become a bottleneck.

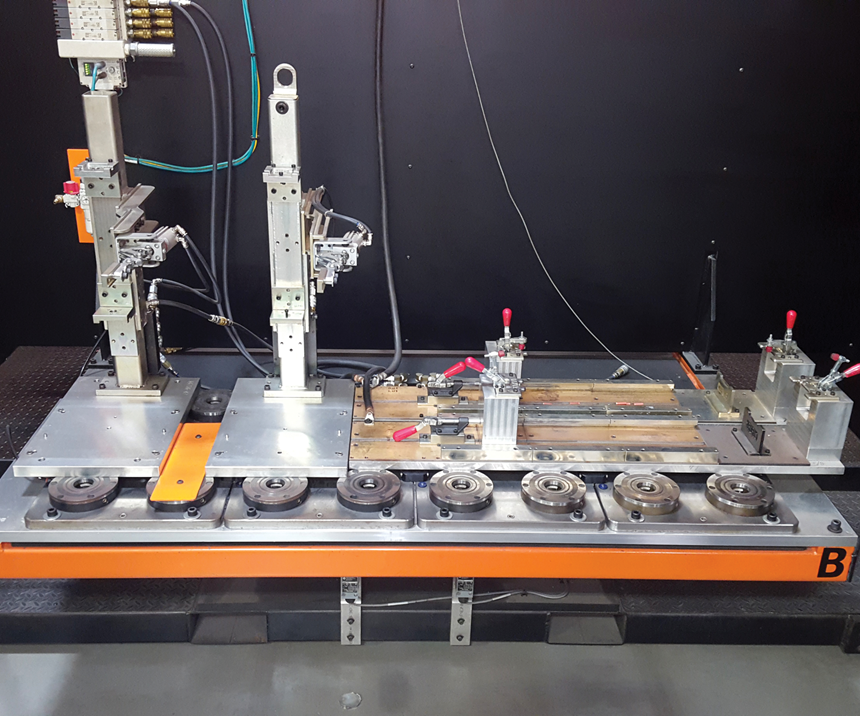

Palletized fixtures are another great option to consider. They allow for higher density parts, offer a starting point for parts in raw form, can be set up for secondary operations, allow faster changeover between batches and reduce the number of tool changes. Once designed for a shop’s needs and tested, pallets can be put on a shelf for storage until needed again. However, they have reduced rigidity, can take up more machine travel and volume, and ROI can take longer to recoup.

As far as mounting directly to the table, not all sizes of workpieces are candidates. Different size workpieces pose different obstacles. Smaller workpieces aren’t viable options. With a medium-size workpiece, mounting directly to the table becomes a consideration. For larger, multi-man size workpieces there’s no financial justification in making fixtures and you need to mount directly to the table, eliminating the need for fixtures. Direct mount provides stability and rigidity, allows for maximum machine travel and volume, and involves no fixture costs. Downsides include increased labor costs due to setup, possibly causing a bottleneck in production, and not being able to perform operations that go all the way through the part.

Lastly, automated systems are the pinnacle of flexible systems because they generally have pallets that can be loaded and unloaded automatically. They have no operator variability or human speed limitation, are highly repeatable, and allow for unattended machining and overnight production. The high-throughput capability frees up personnel to complete other tasks. Automated systems, however, also come with higher start-up costs. ROI can take longer to realize if the production volume is not high enough, and they’re dependent on part and/or fixture consistency. Although, depending on certain machines, the machine builder may have an automated system that can be added to a machine quickly, eliminating the need for re-engineering or building an entire system from scratch.

Each workholding option comes with its list of pros and cons, so be sure to contemplate this and see what works for your shop.

About the Author

John Zaya

John Zaya is the product manager for workholding at BIG KAISER Precision Tooling (Hoffman Estates, IL). John earned a Bachelor of Science degree in Mechanical Engineering Technology from Michigan Technological University. Prior to joining the BIG KAISER team in 2006, Zaya spent time at several machine shops. John can be reached at (224) 770-2930 or john.zaya@us.bigkaiser.com.

Related Content

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreTool Balancing Equipment Ensures Consistent Moldmaking Results

Zoller enables balanced toolholders, tool assemblies and grinding wheels using its »toolBalancer« series, providing high-quality surface finishes and extended surface life to spindles and cutting tools.

Read MoreToolholding, Metrology Systems Increase Accuracy and Efficiency

IMTS 2024: Rego-Fix introduces automated tool clamping units, spindle drawbar force testing tool for increased efficiency, measurement accuracy and machining capabilities.

Read MoreHydro Chuck Toolholder Promises Precision When Heavy Milling

Precision cutting tool solutions manufacturer NT Tool presents Hydro Chuck Omega, designed to eliminate the common issues of chatter, deflection and pullout.

Read MoreRead Next

2019 Sourcing Guide: Cutting Tools

MoldMaking Technology’s annual Technology Review and Sourcing Guide is a comprehensive guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including cutting tools.

Read More2019 Technology Review: Cutting Tools

MoldMaking Technology’s 2019 Technology Review and Sourcing Guide offers some of the latest highlighted products and services from supplier companies from a variety of categories, including cutting tools.

Read MoreBig Kaiser Hosts Annual Breakfast and Learn Event

Big Kaiser Precision Tooling, Inc., a leader in premium high-precision tooling systems and solutions for the metalworking industries, will host its annual Breakfast & Learn event May 13-16.

Read More

.jpg;maxWidth=300;quality=90)