MMT Blog

"Adding" onto the Manufacturing Strategy

Earlier this month at IMTS--The International Manufacturing Technology Show 2012--The Association For Manufacturing Technology made available its second generation of The Manufacturing Mandate, which emphasizes collaboration as a crucial element to solidifying the renaissance in American manufacturing. One such recent collaboration involves additive manufacturing.

Read MoreYoda Sighting at IMTS!

Okay, so he may not have originated from a plastic injection mold, but it’s my blog, right?! And, how cool is he!! This rendition of Yoda was actually created from nine sheets of plywood—90 layers total.

Read MoreSustaining the Wealth of the Nation

We have all heard the phrase "manufacturing creates wealth," but here is a different way of explaining how America’s manufacturing sector built such a powerful economy: there is another type of wealth that is created by manufacturing, which is the most precious type of wealth there is--manufacturing creates knowledge.

Read MoreI Felt the Pride

Last week I attended a press event for Hyundai WIA during IMTS that I thought was going to be a review of a new machine the company was debuting at the show, but instead was witness to a generous technology donation to a deserving school. However, what I will remember most from that 15-minute event was the pride and enthusiasm gleaming from the faces of each student and teacher in attendance.

Read MoreMultiple Set-ups Versus Turning Capabilities

Video demonstrating the Turn-Cut function available on a horizontal machining center.

WatchSee-Or Better Yet, Be a Part of-Manufacturing Across the USA

A day in the name of Manufacturing! October 5th has been dubbed Manufacturing Day and it was established to help improve the general public's perception of manufacturing--its careers and value to the U.S. economy. This day is set up for students, parents, educators, media, customers, suppliers and the community who will learn about real career opportunities, training and resources. In addition, manufacturers will learn about business improvement resources and services delivered through manufacturing extension partnerships.

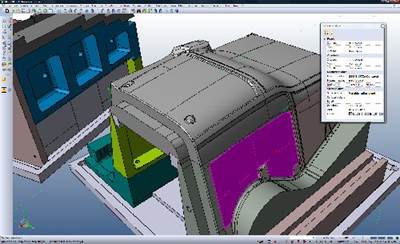

Read MoreDesign Collaboration Produces Tooling Right First Time

DeltaCAD Ltd collaborates with sub contract tooling manufacturer Casting Support Systems on a project to provide a leading aerospace company with aluminum tooling for a carbon composite seat shell for a major civil airline company.

Read MoreMMT TV Time at IMTS

MoldMaking Technology was given some TV time during IMTS on Wednesday. IMTS.tv grabbed me on the show floor to discuss the moldmaking industry, business conditions, future outlook, the magazine's mission and what specific technologies being showcased last week are targeted for mold manufacture. Minus the screen time on my mug, it was a great opportunity for me to promote moldmaking at this mammoth event.

WatchRobots Impress at IMTS

I have seen some incredible demonstrations of technology this week, but this live robot at the Siemens booth (E-5010) was really impressive!

Read MoreMerging Manufacturing Technologies at IMTS 2012

A live demonstration of embracing both subtractive and additive manufacturing was one of the highlights for me at IMTS. Machine tool builder GF AgieCharmilles and EOS showcased an innovative start-to-finish manufacturing process chain that creates actual titanium tibial trays for surgical knee implants.

Read MoreKudos to Award Winner Lifetime Products!

I was honored to attend an Awards Ceremony the other day, hosted by Delcam. The company recently added its 40,000th customer—Lifetime Products Inc.—to its list of more than 90,000 end users from around the world.

Read MoreMold and Die as Key Indicator Brings New Cutting Tool Tech at IMTS

Several cutting tool suppliers here at IMTS predict that moldmaking should continue to demonstrate growth potential as the focus shifts from work sent overseas back to the U.S. As such, many cutting tool suppliers have been motivated to reintroduce and develop technology for this niche marketplace, and here at IMTS there is plenty to see. Here are a few highlights.

Read More

a.jpg;maxWidth=400;quality=70)