MMT Blog

Rising Stars and Scholarships

It's always good to hear about kids who are interested in manufacturing, and it's even better when we recognize them. Both the AMBA and SME have recently done just that.

Read MoreReading the #AAMeter

Last month the Alliance for American Manufacturing reported a gain of 6,000 jobs. Our industry needs to be aware of this, and continue with efforts to address the skilled labor shortage so this number climbs!

Read MoreMoldmaking in the Mainstream?

Will moldmaking in the mainstream help attract a future generation. Going to the source to get honest answers may help. It continues to amaze me how kids today still don't find manufacturing exciting; or, is it that we've just done a very poor job of marketing ourselves. I strongly believe the latter is the hard truth, and something which we need to address hard and fast!

Read MorePerfect Plastics Parts

It's not too often I come across a molder/moldmaker that knows how to market itself as well as set itself up as an "educator" to its current and potential customers. The Rodon Group is one such company and via their blog they share their top four factors for producing perfect plastic parts.

Read More2nd Quarter GDP Stats Indicate that Growth Is Accelerating

If you follow this blog you may recall that last week I warned readers that the rate of economic growth in the second quarter was likely to be quite low. Based on analyses of the monthly data series that measure macro economic activity in the U.S., the most reliable models were predicting that the growth rate for the total GDP figure sank as low as 0.5% in Q2. Well, I am happy to report that this prediction was too pessimistic.

Read MoreMega-Cell: Moldmaking Automation

The Mega-Cell is a production system that ties together all available opportunities to automate and control the process.

WatchAerospace/Defense and Energy/Power Generation

Total Output of Aerospace Products Will Decline This Year; U.S. Demand for Electricity Is Steadily Creeping Higher

Read MoreMold Roughing

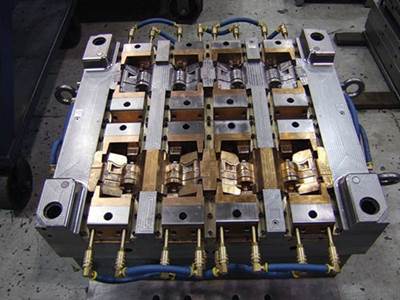

Tolerances and finishes on the Buss Precision's molds are tailored to the specific project, but most work is held to +/-.0002 tolerance on multi-cavity components, cavity, cores and parting lines.

WatchRaising the Bar on Better

A look at one project to move away from traditionally customized moldmaking toward a level of complete automation that raises the bar on accuracy, repeatability and control.

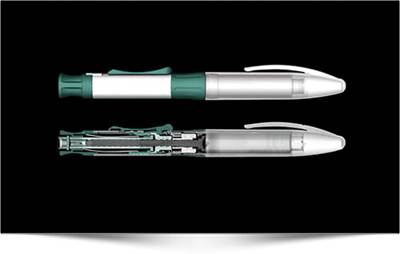

WatchInspecting Highly Complex EDM Projects with Industrial CT Scanning

Industrial CT scanning plays an integral role in the EDM process when it comes to inspecting small, highly complex, detail-oriented parts.

Read MoreCrest Mold Technology: On the Cutting Edge of R&D

“Intense investigation of technologies that can be advanced for applications that give our customers an edge is what Crest Mold research and development is all about.”

Read More