INCOE Corporation designs and manufactures hot runner systems driven by performance for the processing of all injection moldable plastic materials. INCOE is a global company that is 100% family owned and operated with a commitment to supporting the plastics industry, innovating new products and providing top-level customer service.

An experienced team of professionals in over 45 countries remains committed to quality, partnership and bringing application-specific expertise to the customer. According to the company, its original patented design was the first commercial hot runner nozzle available.

A recent conversation with INCOE’s New Business Development Manager Jim Bott and Business Development Manager David Shirley reveals the answers the following questions:

- Incoe offers a variety of technology, which MoldMaking Technology has covered over the years, here we focus on valve gating technology. What is a common challenge you see with customers today for which valve gate pin control technology is the answer?

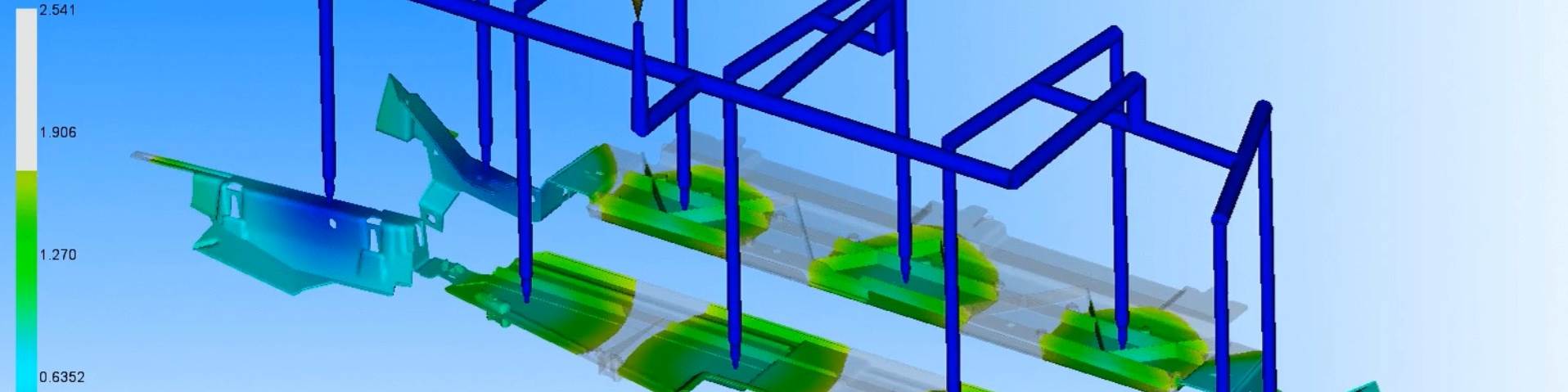

- Let’s move to balanced hot runner systems. I know you partnered with John Beaumont to develop a solution for mold-filling imbalances and cavity-to-cavity variations, can you talk about this scientifically engineered hot runner system, how it’s engineered on a custom basis, what common practice it replaces and how it works?

- Incoe says it ‘partners’ with mold builders to develop the right melt management technology, can you explain what that partnership looks like?

- Can you give me an example of when that helped to develop a specific technology solution?

For more video content from MMT, visit https://www.moldmakingtechnology.com/videos

Related Content

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.