Value-Added Critical Cleaning of Industrial Molds

If you want to build industrial molds right, you have to clean them right.

You have probably put a lot of time and effort into the right design, the right mechanical tools, and the right Q.C. protocol and software for building and maintaining industrial molds. Investing the time to choose the best industrial cleaning processes is worth the effort.

Relatively easy to adopt changes can yield tremendous benefits, so this article will provide a few ideas to improve your mold cleaning processes, improve your bottom line and set you above the competition.

Contaminants Impact Performance

Soil is matter out of place. Soil accumulates during manufacture and use of molds. If small particles, metal or plastic fines, mold release compounds, or any other process material interferes with the performance of the mold, you have to remove it. However, cleaning should be value-added for all applications; mold cleaning is no exception

Identify All of the Cleaning Processes

Cleaning is removing soil. To be sure that you are actually identifying your cleaning processes, keep in mind that industrial and critical cleaning usually involves:

- Chemicals

- Force

- Time

- Temperature

Even if you use water with no additives, water is acting as a chemical. Cleaning can occur in a sink-on-drum parts washer full of mineral spirits, in a tub of soapy water, and in a large, overhead conveyor washer. Have a look at your written documentation; and then walk around the shop floor to see what is actually happening. Some common cleaning problems with cleaning agents are summarized in Table 1.

| Table 1 | |||

| Problem with cleaning agent(s) |

Associated mold production/repair problems | Additional problems | Solutions |

| cleaning agents do not remove soils efficiently |

|

|

|

| large assortment of cleaning agents present |

|

|

|

| “mystery mixes” & household products |

|

|

|

| unacceptable chemicals & processes creep back |

|

|

|

| Common cleaning agent problems and solutions. Table courtesy of BFK Solutions. | |||

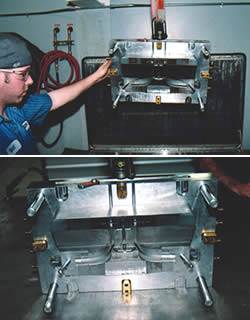

Benchtop or Hand Cleaning

Hand cleaning may be the only practical way to clean molds; and it is typically the least-controlled cleaning process. Usually, such cleaning is at room temperature; and the force is provided via elbow grease. Look over the cleaning agents that you, your employees or your service technician is using. If there are assorted bottles and aerosol sprays, it is probably time to define what can and cannot be used (see Figure 1).

Many people think all cleaning agents are alike. Not so. Matching the cleaning agent to the soils gives faster, more thorough cleaning. All too often, the person in charge of cleaning grabs the first bottle or spray can on the shelf. Each technician may have a particular favorite. You would not think of letting each technician design a mold differently; the same should hold for cleaning.

Limit and Define the Cleaning Agents

In addition to wasting time and money, using a random assortment of cleaning agents can actually cause more problems than they solve.

The cleaning agent itself can cause residue build-up; the mold may actually be more soiled after the cleaning process. If you look at the mold carefully after cleaning, or test the cleaner by repeatedly applying it to a polished metal surface, you can very often see this residue. Some cleaning agents, including water-based cleaning agents, have high levels of non-volatile additives like salts that adhere to the surface of the mold.

Other cleaning agents, including some solvents and aerosol blends, may ultimately evaporate, but, because of extremely high boiling points, they adhere to the surface, forming a sticky or oily residue. Many bio-based cleaning agents such as orange terpenes, pinenes, soy oil, or other vegetable oils can remove soils, but need to be rinsed to avoid build-up on the surface. Some of these natural products can oxidize; this means the chemical nature changes; when this happens, aside from flammability issues, the residue can be even more adherent.

Quality, Responsible Cleaning Agent Suppliers

It is tempting to use household cleaners on molds. Your workers may obtain them at the local supermarket or hardware store. The packaging and advertising may indicate “Xtra cleaning power!!!” But, it is recommended that if you use consumer, household products, to replace them with something else.

Household cleaners are designed to be pleasant for consumers. Therefore, they may contain perfumes and lotions that can leave a deposit of residue on the mold. This is a particularly important consideration where spray or aerosol bottles are used repeatedly and at the discretion of the technician. In addition, many consumer products are designed to hold soils in suspension, so if you immerse the mold in the cleaning agent, there can be enough soil buildup in the tank that you are actually redepositing soils on the part. Finally, consumer products are subject to reformulation without notice, which is why phrases like “new and more powerful” appear on the label. The reformulated product may behave quite differently. If the product is for consumer use only, you have no one to complain to.

A few consumer products might be termed “cross-over” products in that they are supported for both consumer and industrial product applications. There are two exceptions where you might consider consumer products:

- The supplier provides assurances that the product is suitable for use in industrial product cleaning.

- There are accessible chemists or technical support specialists.

In fact, service and product support are important considerations in selecting any cleaning agent for the manufacture or maintenance of molds. There are many suppliers and formulators of industrial aqueous cleaning agents. With all cleaners, find out:

• What you are cleaning with.

Beyond the label, there needs to be an MSDS. Read it; and, if it does not provide enough about the actual ingredients, ask for information. This is important for worker safety, environmental compliance and product quality. Many blends contain materials that are not listed on the MSDS because they do not impact the employees, but they may impact product quality.

• Which technical person to contact in case of problems.

Sales reps vary considerably in their knowledge and understanding of cleaning agents. If you run into problems, you need support beyond vague assurances that switching from the red bottle to the blue bottle will solve everything. Particularly if molds will be used in critical applications like aerospace or biomedical, call the technical contact before you start using the cleaning agent.

Understand the Customer’s Cleaning and Surface Residue Requirements

While we all know that the customer is always right, taking the time to understand the critical surface cleanliness requirements of the customer can distinguish you from your competition, particularly for aerospace and medical applications. In aerospace, particles and non-volatile residue (NVR) are the two workhorse requirements for cleanliness. In some critical applications, the customer may need to avoid specific chemical residue.

When you think about regulatory requirements, the Environmental Pro-tection Agency (EPA), the Occupational Health and Safety Administration (OSHA), or a local air or water quality agency probably comes to mind. When medical device manufacturers discuss regulatory issues, they are often referring to the Food and Drug Administration, whose requirements involve product cleanliness; often this is referred to as product residue.

With medical devices, Total Organic Carbon (TOC) has been one historic indication of cleanliness. However, with increasing expectation for the longevity of medical devices (along with the longevity of the people receiving those devices), there has been increasing realization that TOC is not enough. In part, this is because organic carbon could indicate the presence of any of untold numbers of organic compounds. The dose makes the poison; and in medical devices, many otherwise benign materials can be an issue; so there are many potential poisons. In medical devices, toxicity and level of the poison have to be considered.

There are several national and international standards that medical device manufacturers currently use. One ex-ample is ISO-10993-17 that deals with characterizing leachable residue from medical devices. Others are Federal Regulation 21CFR-820 and ISO Standard 13485:2003 that relate to establishing and documenting a Quality Management System (QMS). The Federal Regulation applies to devices for U.S. applications; the ISO Standard 13485:2003 applies to most non-U.S. applications. The standards give responsibility to the final assembler; and they also impact facilities involved in earlier stages of production, perhaps your shop.

Identify the Cleaning Challenges, Stay Profitable

Your competition may consider that as producers of molds or as the shop that maintains the molds, they are not concerned with final assembly or fabrication. You, on the other hand, can be forward thinking; you understand that residue from mold manufacturing and mold repair can impact the final product.

Forward-thinking companies look at the full impact of surface cleanliness and surface quality on final product performance. Therefore, even if a potential customer does not provide specific cleaning or residue requirements, it is prudent and profitable to raise the issue with them.

Of course, first you have to understand the sources of contamination, how to minimize contamination, and how to remove contamination that cannot be avoided. Cleaning and surface preparation issues present challenges to the mold engineer, the mold builder and the mold repair technician. Your optimal solutions depend on your product, your production situation and the requirements of your customer. Step back and look at your current industrial and critical cleaning processes. Even if you cannot figure out all the solutions, you will identify the problems—a great first step.

![]()

Related Content

Questions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MoreHow to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MorePrecision Welding Services Offer Rapid Turnaround Mold Repair and Reduced Molder Downtime

X-Cell Tool & Mold relies on outsourced, high-quality welding repairs from Lewis-Bawol Welding to ensure its customers' molds are back in production quickly and affordably.

Read MoreRead Next

Streamline Your Mold Cleaning Process

Ultrasonics can help your shop reduce labor costs and product waste while boosting efficiency and product quality.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More