Share

Read Next

Last year, we met Jack and Mike and learned about their successful company and the challenges they faced as they strategized for growth. Through a series of meetings and discussions to overcome these challenges, Jack and Mike resolved to refocus the company on customers by developing processes and systems to prevent problems for customers.

The overall framework they used was called process maturity, which laid out the path for Jack and Mike to systematically develop the necessary problem-prevention-based systems in the company. As a result, they experienced a breakthrough in employee engagement, resulting in enthusiastic buy-in, participation and contribution to change.

The next step was working with their re-energized employees to capture the real processes and interconnections within every part of the company. As Jack and Mike started to understand the real processes of the company better, they also started to understand the power of data to help improve outcomes. It was hard to avoid all the press articles and reports on digital transformation, but what it was and how to do it was not clear.

“So when are we going to get started implementing all this digital transformation stuff,” Jack jokingly asked Mike one day. Responding in kind, Mike said, “As soon as we figure out what it is exactly!”

Defining Digital

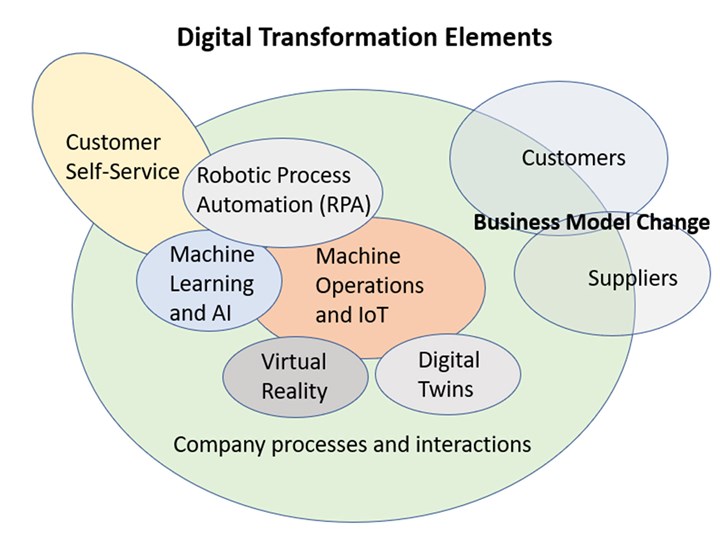

Research on the topic revealed a multitude of terms and meanings for digital transformation, including the Internet of Things (IoT), Industry 4.0, virtual reality, digital twins, robotic process automation, smart applications, machine learning and artificial intelligence. It was clear that digital transformation by itself was a generic term for many different concepts that may include a focus on customer interaction, internal processes, machine operations and/or actions to reduce downtime or improve outputs. Digital transformation could even include a complete change in the business model and how establishing new ways to work with customers and suppliers.

Shops must choose the right elements of digital transformation to pursue based on the shop’s business objectives. Images courtesy of 4ABetterBusiness.

After much discussion with the team, Jack and Mike concluded that digital data was the only common element among all of these concepts. So, they started evaluating their current data collection, analysis and usage. What they discovered was that the metrics in place were not effective for moving the business forward. Their metrics did not link to the success of the business (they measured activities, but not outcomes); they did not link to the process, yielding ambiguous results; they did not prove useful for monitoring performance or taking action, and they did not allow people to connect their actions to the results.

While they recognized data was important, Jack and Mike decided to dig deeper before generating more data. They wanted to get a better handle on the data the company already had and how the team was using it. That exercise revealed the following:

- Data quality was poor. Information in the ERP system was inaccurate and inconsistent, leading employees to develop their systems at a further cost of productivity and accuracy.

- The company was using an overabundance of Excel files, with each one dedicated to a local purpose and not linked to other data.

- The company was collecting data, losing it, then trying to find it again at another point in the process. The excessive number of Excel files, and for example, using different names for the same data, were clearly factors preventing data flow and accessibility.

- Old “rules of thumb” and tribal knowledge were driving many activities. They were not incorporating important knowledge into their decision-making, which created resistance to change, increased employee turnover risk and made it harder to quickly develop productive employees.

- Existing data had no clear ownership in terms of who was requesting the information and what the plan was for collecting, maintaining and acting on the data.

As the team resolved these issues, the right metrics became apparent, data quality markedly improved and they were able to establish clear links between data analysis, actions to take and the improved results achieved.

Going Digital

Jack and Mike often heard tales from colleagues about putting technology in place and then trying to figure out what to do with the data, without much success.

It seemed to Jack and Mike that digital transformation involved a lot more than buying technology. Jack and Mike wanted to set a clear direction on the business objectives for applying digital transformation, identify the type of data that would help them better run the business, and then decide on the necessary technology to provide what the team needed to improve the business.

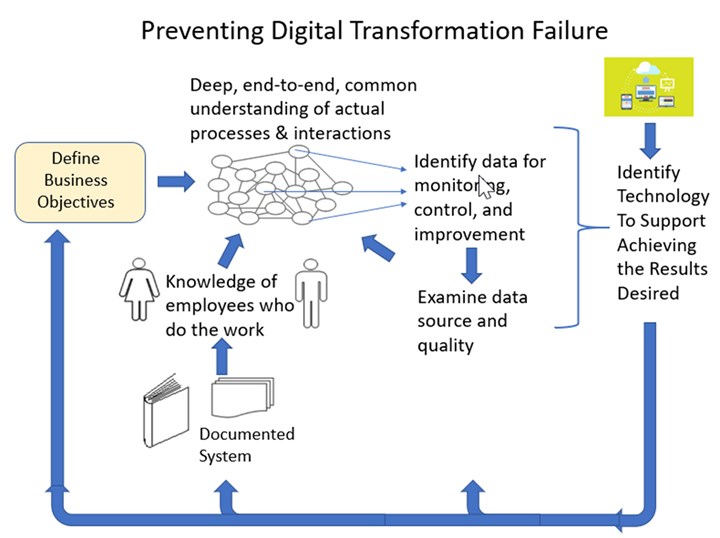

Shops can prevent digital transformation failure by determining their business objectives, involving employees closest to the work, developing deep, end-to-end process understanding, identifying data needs, validating data and then choosing technology that meets the shop’s needs.

Jack, Mike and the rest of the team came up with a five-step strategy:

- Define clear business objectives.

- Engage the people closest to the work to ensure they have a deep (and common) end-to-end understanding of the processes involved in achieving those business objectives

- Establish the data that the team will use to monitor and support the achievement of those objectives.

- Examine the source and quality of the data.

- Identify the technologies that will support achieving these results.

In their eagerness to move on to a solution, in the first project the managers jumped over the second step (engaging people closest to the work), believing that they already understood the processes. As a result, the effort fell apart.

It turned out that the processes worked the way they thought (and according to the documentation) for about 80% of the cases. However, for 20% of the cases, the processes did not work together as documented, and employees were spending 80% of their time on the 20% of cases. These discrepancies made it difficult to establish reliable and meaningful metrics.

For the next project, the managers included step two and engaged the people closest to the work to help identify and resolve issues that were causing loss of productivity and time. The savings from resolving these issues turned out to be a significant source of funding for technology solutions that would further accelerate improvement.

As the team resolved these issues, the right metrics became apparent, data quality markedly improved, and they were able to establish clear links between data analysis, actions to take, and the improved results achieved.

Jack and Mike began to see digital transformation not as a one-time event, but rather as an ongoing process integral to the operation of the business. Now, they set out to use the process to understand and tackle the aspects of digital transformation that would provide the biggest bang for their buck.

Related Content

What You Should Consider When Purchasing Modified P20 Steel

When buying P20 steels that have been modified, moldmakers must be aware of the variations and key issues that affect delivery, cost and lead times.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

Systems and Structure Empowers Employees and Reduces Challenges and Leadtimes

A team will achieve company objectives and improve customer service with a common understanding of processes.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More