Systems and Structure Empowers Employees and Reduces Challenges and Leadtimes

A team will achieve company objectives and improve customer service with a common understanding of processes.

This is a story about two experienced moldmakers, Jack and Mike, and the formation and ongoing development of their successful mold manufacturing business. The story is built around the challenges many shops encounter as they grow and describes some practical steps to develop buy-in and participation in change and scalable processes to enable growth.

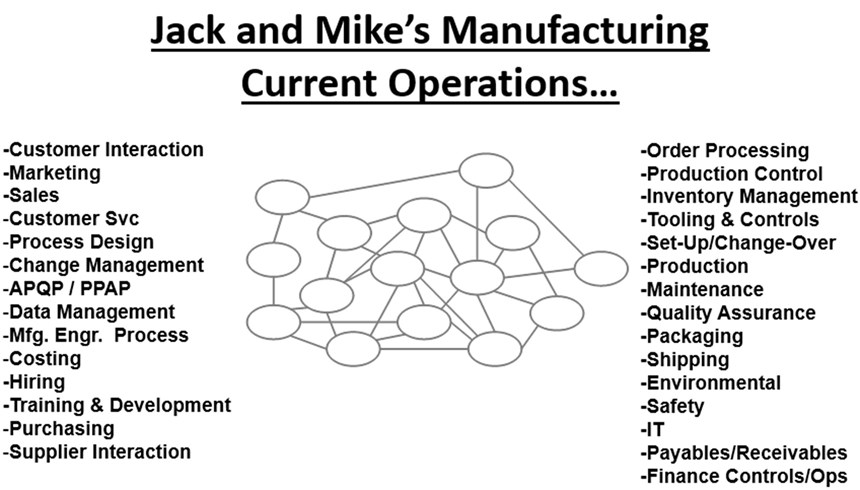

Jack and Mike launched a new mold shop business based on long-standing industry relationships. The business started small, but with hard work, the shop developed a reputation for quality and on-time delivery. Soon the business grew beyond what the two men could handle alone. They hired a sales person to develop more business, a mold designer and staff for the production department. Then they started to focus on larger and more complex molds, which demanded more staff for the additional machinery they acquired to do the work.

As the business continued to grow, work previously handled by one person was divided among three or four people, depending on the area. People working in a specific area grew to understand the details of “who does what”. Eventually Jack and Mike grew the workforce to include a program manager, quality manager, mold design team, metrology specialist, plastics engineer, CNC machine operators, manufacturing process engineers and assembly technicians.

All this was done without a lot of documentation, relying on employees to work together. Employees often adopted their own “local” standards for mold features, tooling, tolerances or other aspects of the mold or manufacturing, resulting in “tribal knowledge” only known to a few.

Jack and Mike added technology in bits and pieces, too. Keeping track of everything on paper and in Excel started to get out of hand. They bought a scheduling system. When they outgrew that, they bought a full manufacturing resource planning (MRP) system. The MRP system didn’t meet all of their needs, but it seemed to work well enough to get them to the next level of operations. Somehow, it always took a long time to get anything new working right. More experienced employees would continue to use old approaches.

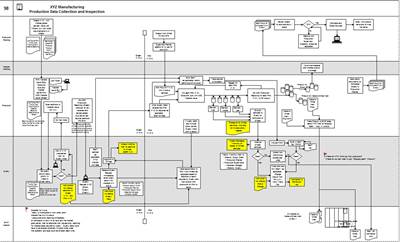

Once they established the visual processes, they could define the data they wanted to analyze, use and link to a process for improvements. As everyone gained a better understanding of processes and interconnections, the company defined sensible metrics more easily and directly connected data to processes.

Losing Focus

With growth came new issues. For example, a type of job that had always run smoothly through the shop suddenly ran into problems. The lack of documentation and dependence on tribal knowledge became more problematic, as people moved departments or left the company. The frequency of errors continued to increase, and customers noticed it was impacting lead times.

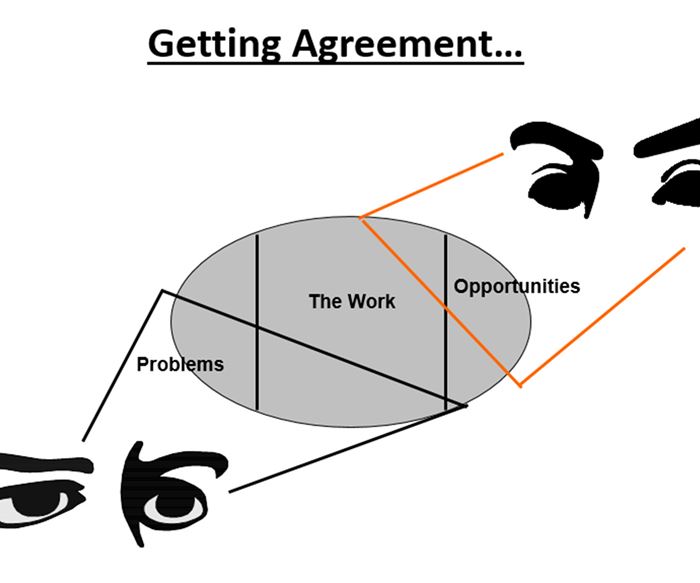

As these problems occurred,Jack and Mike would figure out a solution and send a notice to meet with the involved employees and discuss the problem. It became apparent in these meetings that even people working in the same area had different ideas about how things actually worked. As a result, there were disagreements on proposed solutions.

The data they collected wasn’t much help, as it was seldom clear whether the data was helping to pinpoint a problem or simply identify when someone with the tribal knowledge was absent. When a change was implemented, it often didn’t solve the problem, or worse yet, created a new problem. In a few weeks, everyone went back to the prior way of working.

Jack and Mike tried encouraging employees to make suggestions on how to make things work better. The suggestion boxes they put up were rarely used. Then they tried encouraging everyone to take action in their own area. People offered ideas to their managers, but managers were often pressed for time to handle problems, and so, they would not take any action. Not surprisingly, the flow of ideas stopped.

Jack and Mike then set up teams to address involvement across all functions. They sent leaders to training courses on how to manage teams and how to run effective meetings. Once the effort got off the ground, the teams got bogged down with formalities rather than addressing the pressing issues. Soon people stopped going to the meetings, and the effort dissipated.

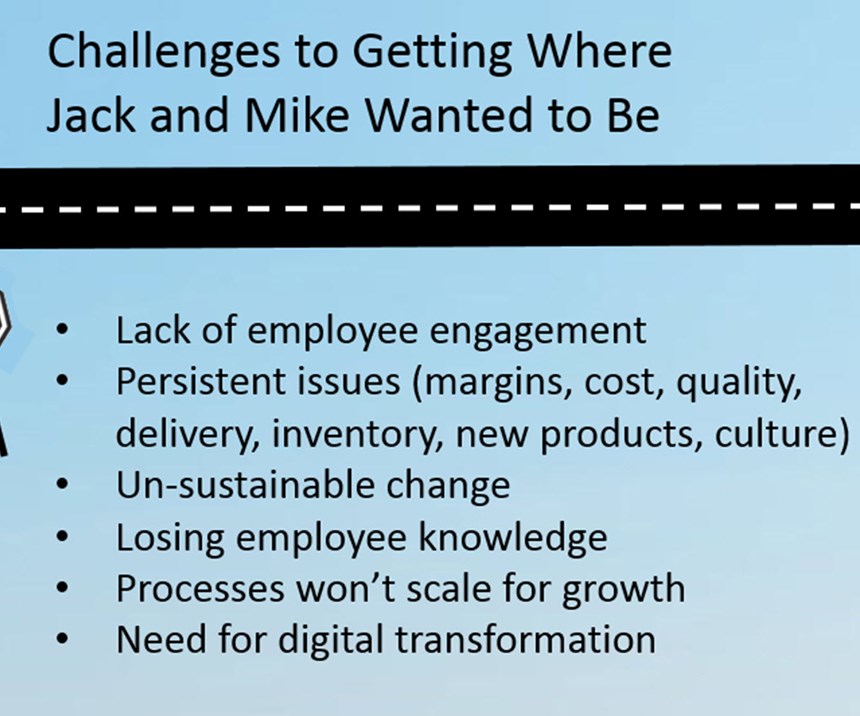

Jack and Mike even tried brainstorming sessions with management about what customers want and what customer do not want. This exercise revealed that customers want short lead times, quality, added service, responsiveness, technical capabilities and no problems. Jack and Mike then categorized areas with problems that impacted the customer. These problems included lack of employee engagement, persistent issues (margins, cost, quality, delivery, inventory, new products, culture), unsustainable change, losing employee knowledge with retirements, departures or changes of assignments, inconsistent processes that don’t scale for growth and the need for digital transformation. Everything seemed to result in increased lead time.

Now with a common understanding of processes and interactions, the company easily identified opportunities for adopting Industry 4.0 and other new technologies, as well as a significant addition to the MRP system.

Taking Action

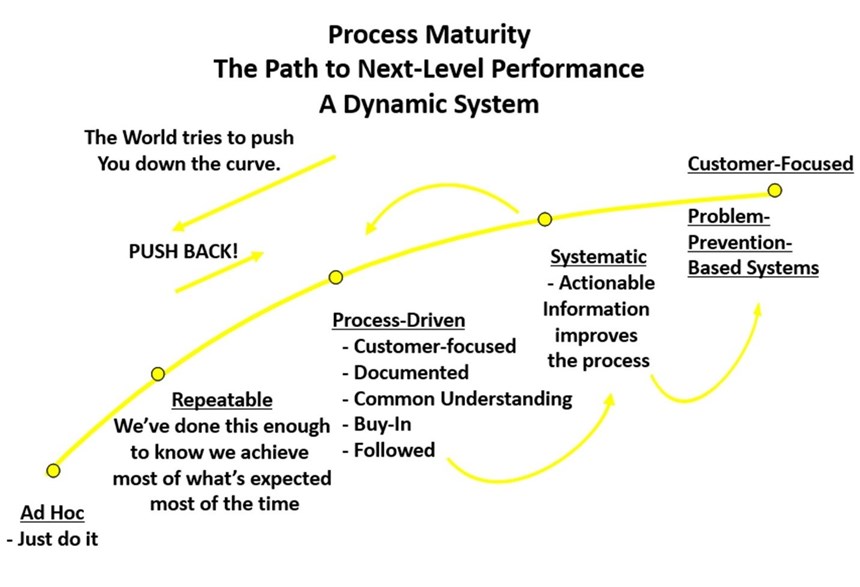

The outcome of the brainstorming session identified that customers wanted “everything with no problems.” Jack and Mike decided that to accomplish this goal, the company needed more than a “better way to work,” it needed customer-focused, problem-preventing systems. The overall framework used is called process maturity. One key aspect of the model for Jack and Mike included steps for moving beyond the repeatable stage, called the process-driven stage. The first step to developing these systems is recognizing that employees are the experts within their local systems and processes, and that almost all issues in a company are embedded in how the local systems and processes work and work together.

The characteristics of this new problem-preventing system are:

- Customer focused. Take into account the customer journey or experience in addition to shifting the focus streamline internally.

- Documented and common understanding. Documentation by itself does not develop common understanding, which is particularly true with text-based systems such as the numbering systems of ISO 9001 and related standards. For example, one section of a standard can apply to multiple parts of the business, and one part of the business may address multiple parts of the standard. This “many-to-many” relationship makes it difficult for employees to decipher how the different parts of the business work together. Companies using visual documentation, such as deployment flow charts, will more easily see inputs, outputs and interactions as well as risk, responsibility and authority. Well-understood processes make it easier to scale and implement digital transformation.

- Buy-in and followed. Defining a change and then trying to get employees to buy-in and follow that change is a typical strategy, but it often develops resistance to change. A more effective strategy is to start with the end in mind by identifying what is actually happening and what the company is currently following. As a company works through this process, it will discover the real issues impacting the business, for which it can gain employee participation and contribution to develop sustainable solutions, as well as buy-in to the solutions and ownership of the results.

Jack and Mike understood clearly that transitioning to a process-driven stage using data would help the company move beyond the repeatable stage, which was heavily dependent on tribal knowledge. Once they established visual processes, they could define the data they wanted to analyze, use and link to a process for improvements. As everyone gained a better understanding of processes and interconnections, the company defined sensible metrics more easily and directly connected data to processes.

Now with a common understanding of processes and interactions, they easily identified opportunities for adopting Industry 4.0 and other new technologies, as well as a significant addition to the MRP system. On top of that, customers began noticing the change in the company’s ability to address and prevent problems, even on projects in process. Employees were finding and addressing problems immediately, without finding fault or blame. With the new system, employees applied a consistent process to each project and got the unique results each project requires.

Over the next few weeks, as everyone in the company was engaged in process capture and assessment, the initial buy-in developed into participation in the change. Since they were clearly part of the solution (not viewed as the source of the problems), managers and employees developed ownership in the changes made and the results achieved. With a full view of the system and everyone contributing, they quickly resolved some problems the company struggled with for years. As a result, they created a roadmap for future actions and redefined their “way of doing business”.

Jack and Mike saw attitudes and expectations change from resignation to problem-solving. They called it their “improvement seeking” culture and began to see that the positive work environment gave the company a competitive advantage in attracting and retaining employees.

About the Author

Paul Vragel

Paul Vragel is president of 4aBetterBusiness.

For More Information

4ABetter Business

4abetterbusiness.com \ 847-606-2605 \ pvragel@4abetterbusiness.com .

Related Content

Top 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

Read MoreMMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreRead Next

Visual Tools Facilitate ISO 9001 Certification Upgrades

Capturing and visually documenting the processes of your shop with your employees maintains focus on business improvement not just compliance.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More