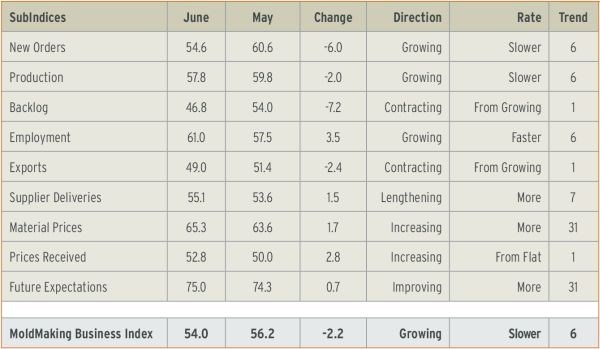

With a reading of 54.0, the MoldMaking Business Index showed that the moldmaking industry expanded in June for the sixth straight month and the eighth time in nine months. The rate of growth in May was the industry’s slowest since February. This appears to have ended the uptrend that began last August. The month-over-month rate of change was 7.8 percent in June, which was the fourth consecutive month of month-over-month expansion. The annual rate of change has grown at an accelerating rate each of the last four months.

New orders grew for the sixth month in a row and the eighth time in nine months, however this rate of growth was the slowest since February. Production has expanded every month but two since January 2013. The backlog index contracted for the first time since February, but, compared to one year earlier, it increased by 6.8 percent, which is the fourth month in a row of month-over-month increase. The trend in backlog is indicating higher capacity utilization levels and capital spending. Employment has increased at a significantly accelerating rate since February. In June, the employment index reached its highest level in the history of the index. After growing in May for just the second time since December 2011, exports contracted in June, but, the export index has been trending up since February. Supplier deliveries continue to lengthen at a fairly normal rate.

Material prices increased at a faster rate in June, but the overall trend in the material prices index has been down since February. Prices received increased for the first time since March, growing at their second fastest rate this year. Future business expectations ticked up in June and remain at a relatively high level.

Plants with more than 250 employees continue to grow at an exceptionally strong rate. Their index has been higher than 60.0 in four of the last six months. Facilities with 20-249 employees saw an increase in business activity in June compared to May, but facilities with fewer than 20 employees were the main reason the industry saw slower growth overall. In May, these small facilities saw their index jump to 57.4, but in June, their index crashed to 43.8. These small facilities have seen only two months of growth since August 2012.

Both custom processors (molders) and metalcutting job shops (moldmakers) have grown five of the last six months, but the rate of growth at custom processors has decelerated each of the last two months. However, metalcutting job shops continue to grow at a strong rate; their growth rate in June was the third-fastest since June 2012.

Future capital spending plans for the next 12 months were more than $1 million for the fourth month in a row. Compared to one year earlier, future spending plans increased 59.5 percent, the fastest rate of growth since last November. The annual rate of growth accelerated in June, reaching its fastest rate of growth since January.

To see the historical breakdown of our business index and each of its subindices, visit gardnerweb.com/forecast/moldmaking.htm.

Related Content

Think Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreMaking Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreTop 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.JPG;width=70;height=70;mode=crop)