Share

We are only halfway through 2022 and we have already seen a lot of new and exciting products in the moldmaking industry. From software to machining, our audience has been reading about some exciting innovations this year. The MMT Team has compiled a list of the top ten most-viewed products this year based on Google Analytics.

Revisit some of your favorites or read about the products that you might have missed.

10.CAD/CAM Software Advancements Anticipate More Efficient Production

Hexagon’s Manufacturing Intelligence has revealed future capabilities for its EDGECAM 2022 software, as well as the “manufacturing aware” WORKNC CAD feature for mold and die makers. The software supports 3+2 machining and complex five-axis simultaneous milling in all configurations.

9. Reliable Mold Damage Prevention Achieved Through Ejector Assembly Securing System

Hasco America’s magnetic system is installed in the riser area of an injection mold to prevent unintentional movement during transport. It guarantees damage-free transport of injection molding tools, incorporating a magnet solution to secure the ejector assembly.

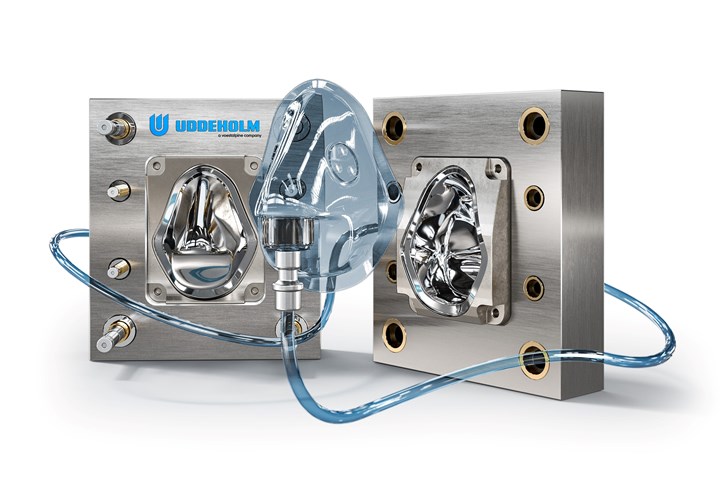

8. Corrosion-Resistant, High-Hardness Mold Steel for Optimal Surface Finishes

Uddeholm’s Tyrax ESR is a premium corrosion-resistant and high-hardness (up to 58 HRC) mold steel. It offers excellent polishability, says Uddeholm, making it a great choice for applications where surface finish is important.

7. Laser Welder Optimizes Mold and Die Repair Expenses

Using Sunstone Welders’ Orion Combo 200 laser welder, companies are able to easily maintain or repair expensive molds on their own. The Orion Combo 200 is said to make fast work of shaping and adding metal to worn or damaged molds and dies.

6. 3D-Printed Tooling Platform Ramps Up Injection Molding Tooling Capabilities

Nexa3D and Addifab have teamed up to provide faster, cheaper and greener injection mold tooling via a novel 3D-printed injection mold tooling platform.

5. Turnkey Package Enables Optimized Automation Integration

Kurt Workholding and its distribution partners at Absolute Machine Tools have created an automation package featuring a Mitsubishi Electric Automation LoadMate Plus plug-and-play cell, Kurt 3600A Pneumatic Vise and Kurt RV36 Robotic Gripper working in tandem with a Tongtai VP-10 mass production high-speed vertical machining center.

4. Integrated Software Platform Adds Product Design, Simulation Extensions

Autodesk Inc. has made available the Production Design Extension and Simulation Extension, which have been added to Fusion 360, the company’s integrated 3D CAD, CAM, CAE and PCB software for product design and manufacturing. Initially highlighted during Autodesk University (AU) in 2021, these extensions improve the platform’s performance, user experience and efficiency.

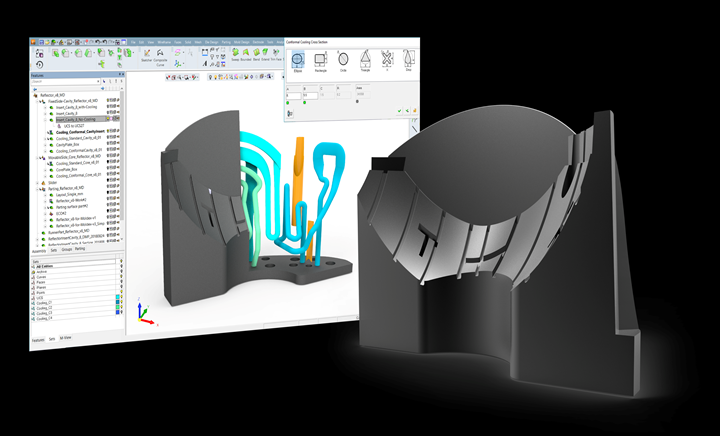

3. End-to-End Conformal Cooling Design, Production for Faster Cycle Times, Boosted Part Quality

To avoid longer cycle times, warpage and sink marks on the part, Cimatron, presents its intelligent conformal cooling channel design for faster cycle times, better part quality and a more efficient cooling process.

2. Excellence Center Enables Innovation Manufacture of Molds, Dies

The DMG MORI Die & Mold Excellence Center highlights its DMU 210 P machine maximized to produce highly demanding molds and dies with quality and precision.

1. Automated, CO2-Based Blast Systems Specializes in Cleaning Mold Surfaces

Cool Clean Technologies, utilizing CO2-based technology, has shifted its focus from gentle CO2 spray cleaning solutions to incorporate a powerful, blast cleaning product to clean various surfaces, molds and tools. The company’s Omega CO2 cleaning solutions specialize in cleaning mirrored finishes and micro molds, by removing thin films, residues and oils from the mold surface that create defects on a molded part.

Read Next

Speed, Productivity Gains and High Uptime Ease Decision for Second Five-Axis Machine

Byrne Tool + Design reduced setups and gained speed and productivity thanks to fast, accurate and compact five-axis CNC machining centers.

Read MoreMoldMaking Technology's Top-Viewed Content in 2022 So Far: Features

A list of the most-viewed features in MoldMaking Technology from January-May 2022, from vertical machining to achieving the best mold finish. Give your favorites another look or catch up on what you might have missed.

Read MoreCeramic Deburring, Deflashing Tools Take Into Consideration Difficult Materials, Operator Safety

Boride Engineered Abrasives introduces its new mold polishing equipment, the Work Finisher Tool, which is lightweight, long lasting, won’t rust and is safer and easier to use.

Read More