The New Rules of Innovation

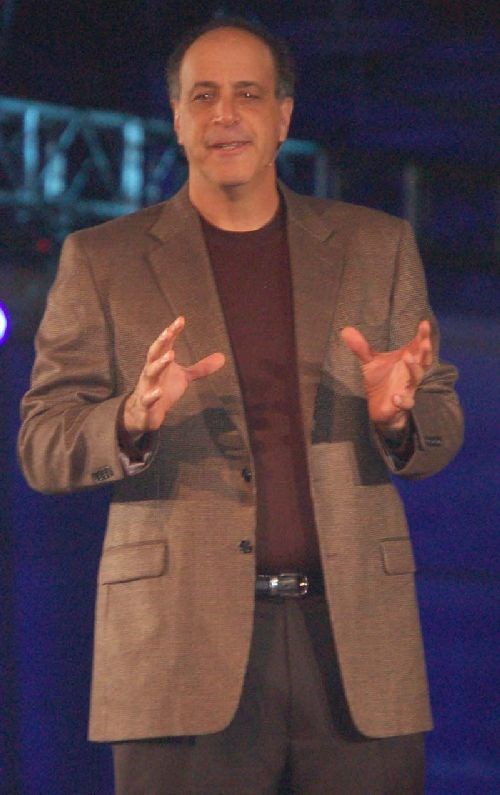

"Focus on agility and innovation because quality is expected." That was the message of Carl Bass, president and CEO of Autodesk, in his address at an indusry event last month. He defined innovation as "making products that differentiate you from your competition" and explained that agility is "how quicky you can bring a product to market." Both are quite apropos for today's mold manufacturer.

"Focus on agility and innovation because quality is expected." That was the message of Carl Bass, president and CEO of Autodesk, in his address at an indusry event last month. He defined innovation as "making products that differentiate you from your competition" and explained that agility is "how quicky you can bring a product to market." Both are quite apropos for today's mold manufacturer.

He went on to dissect five critical trends in manufacturing:

1. Access and experience instead of ownership. For example, no more buying CDs, we simiply download music.

2. Business being un-usual. For example, model of the venture capitalist is being disrupted with "crowd funding" and "crowd sourcing;" use of kickstarter.com.

3. Digital fabrication. For example, additive manufacturing; additive with subtractive manufacturing; shape complexity comes free; nanoscale technology.

4. Access to information. The rise of information.

5. Infinite computing.

Mr. Bass also cited three very innovative companies to check out for their accomplishments despite their size: Moon Express, Lightning Motor Cycle and Cambrian Genomics.

Related Content

-

What is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

How to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.