The MME Group: From Moldmaker to Mold Manufacturer

This moldmaker has evolved into a full-service contract manufacturer by adopting continuous improvement and lean manufacturing initiatives combined with a focus on quality control.

|

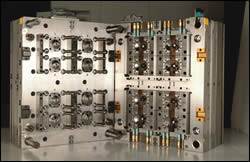

Known as Minnesota Mold and Engineering when first profiled nearly 10 years ago in MoldMaking Technology, the MME Group (Vadnais Heights, MN) has evolved into a full-service contract manufacturer. MME Group increased their end-to-end offerings to include: product development, engineering, program management, plastic and metal tooling design, tool construction, custom injection molding, LIM, and cleanroom. MME Group also provides additional value-added services including: sub-assemblies, pad printing, paint, sonic weld, sterilization and other deliverables to serve the medical, telecommunications, consumer, automotive and government industries. A number of changes have taken place in the organization over the past decade. Changes in the world’s manufacturing landscape led MME Group President Robert Archambault and Vice President of Operations Brian Bussmann to springboard off Minnesota Mold’s momentum and develop into this full-service provider. The duo acquired the tooling company in 2004 from its founder, Don Chlebeck, and merged it with the molding to become an end-to-end provider. In 1999, the company had 55 employees. Today, MME Group boasts 135 employees between two locations—a total of 75,000 square feet of floor space. The main building is located in Vadnais Heights, MN; the second location in North St. Paul. “The opening of our newest location in October 2007 is due to our tremendous growth over the past few years,” General Manager Tom Croce states. “The new location houses molding, assembly, pad printing, shipping and receiving, and space for storage. Our Vadnais Heights location remains very active. It will continue to grow and become home to our engineering group, tooling division, support groups, mold development, cleanroom molding and assembly operations.”

From Shop to One-StopOver the years, the MME Group recognized its customers were looking for a one-stop shop that was built for speed. According to Archambault, this realization resulted in the company’s evolution from a toolmaker and world-class tool shop to more of a molder/contract manufacturer. “Our customers are looking for a company that can provide all that they need, and ensure that all the services are fast, accurate and on-time,” Archambault explains. “We are becoming a true contract manufacturer in that we offer more value-added services, which includes assemblies, sub-assemblies and sourcing. We are able to get the project done fast, accurate and on time by driving projects with a concerted effort from the OEM through the entire supply chain. Having most of the molding services in-house has truly helped us maintain aggressive schedules on small to large programs.” “Over the last few years we have had exciting growth and have expanded our floor space,” Bussmann adds. “Our new location will give our customers an opportunity to see our capacity and strength that MME Group has by controlling two locations. We have company veterans spread throughout the company and a great mix of new talent. Over time the customers also have changed. We are working more with OEMs and are involved in projects months and sometimes years before the product goes to production. We also are given more ownership of the project—which drives us to success.”

Quality ManagementMME Group’s Quality Manager Steve Greisinger notes that the company’s goal is to “surpass the customers’ needs” and will do so through quality, service and continuous improvement. “We started and are following the evolutionary quality path known as Quality Management Systems (see QMS sidebar),” he states. “As part of our QMS, we have seen the implementation and modifications with ISO and TS requirements as the systems have changed and matured. Currently, we hold ISO 13485 Medical certification and are currently pursuing TS 16949 Automotive certification. Continuous improvement, along with strong corrective action systems, has been revolutionary in terms of identification and resolution for inefficient, broken-down business and production systems. “It has been identified and published that over the past 10 years non-QMS companies have had extremely high spending issues,” Greisinger continues. “Between 25 and 40 percent of their revenues were going to fixing problems. This is known as the cost of quality—or more accurately—the cost of poor quality. We focus on improving quality (i.e., reduce waste) to help us produce products and services better, faster and cheaper. Our QMS focuses on defect prevention, cycle time reduction and cost savings.”

Continued GrowthMME Group will continue to focus on contract manufacturing over the next decade, Bussmann states. “We are lean-manufacturing driven,” he notes, “and offer our customers turnkey manufacturing solutions. We are focusing more and more on the entire program—concept through production. It is a relief for many customers to have a one-stop location. They can count on MME Group for Design for Manufacturing Assistance (DFMA), sourcing and coordination of the entire program.” To that end, the company has created a 4 Diamond Flow process helps take the project from engineering to tooling to molding and value-added services in a fast and efficient method. “We have very technically strong individuals in all areas that work together to help the customer with all of their needs,” Bussmann notes. “The customer is number one! We will continue to drive to understand our customer’s needs and provide the services that meet or exceed those expectations.” As for physical growth, plans are for MME Group to expand its cleanroom, an aggressive capital plan and another North American location in the 2009 timeframe. “We also are seeing growth in our (LIM) silicone molding due to our ability to provide LIM tooling and molding faster than the industry standard,” Bussmann states. “If we stay diversified in our customer base and services, we will see unlimited growth!”

|

|

Related Content

How to Achieve Unmatched Accuracy in Very Large Workpieces

Dynamic Tool Corp. purchases two bridge-style double-column CNCs to increase the cutting envelope and maintain 5-micron cutting accuracy in the long term.

Read MoreLaser Welder Yields Fast, Precise Mold Repair

Intralox's integration of the Alpha Laser ALFlak has significantly improved their tool room efficiency when it comes to difficult welds and urgent repairs.

Read MoreIn "Hybrid" FIM Process, 3D Printing Complements Injection Molding

Alpine Advanced Materials used a desktop 3D printer and the freeform injection molding process to reduce prototype tooling production time and cost for its customers.

Read MoreSpeed, Productivity Gains and High Uptime Ease Decision for Second Five-Axis Machine

Byrne Tool + Design reduced setups and gained speed and productivity thanks to fast, accurate and compact five-axis CNC machining centers.

Read MoreRead Next

Custom Mold & Design: Making History

This longtime moldmaker’s molds boast long running times and millions of cycles thanks to the best equipment and dedicated employees

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More