Custom Mold & Design: Making History

This longtime moldmaker’s molds boast long running times and millions of cycles thanks to the best equipment and dedicated employees

Custom Mold & Design (Minneapolis, MN) has survived—and thrived—through 42 years in an industry known for its ups and downs. Its ability to rise above these challenges is a testament to its hard-working employees who have the good fortune to work with the latest and greatest equipment and software to produce molds that have a history of running as many as 20 years as well as molds with 20 million cycles.

The company’s specialization in complex, high precision molds also has helped the company excel over the years. Multi-cavity, hot runner, two-shot, metal injection, stack, two-shot, unscrewing, silicone, reel-to-reel and die-cast are among the molds Custom Mold & Design designs and manufactures. In addition, the company prides itself on the fact that they routinely build molds with fully interchangeable cavities and cores.

According to Plant Manager Mark Casey, customers with long-running molds will call to order replacement cores, cavities or inserts with complex shutoffs. “We build them to the numbers, while they continue to run the mold,” Casey notes. “Then, we ship the replacements, they bolt them in the mold, and they work. No fitting or adjustments—they just work! This is a huge benefit if tools are run in various global locations.”

Custom’s Evolution

Duane Treiber founded Custom Mold & Design in 1965 with his first employee, Walt Halberg. Halberg remains at Custom Mold & Design today as a key part of the company’s past and future success. Casey notes that a high quality product, superior service to the customer and a dedication to the well-being of each employee has always been the company’s focus.

Over the years, the company evolved and grew building high precision single cavity and multicavity molds, prototypes and special machining services related to the injection molding industry. “When you are the best at supplying the complex precision tools that a major manufacturer needs to mold their products, you can earn repeat business and recognition,” Casey says. “In Custom Mold & Design’s case, it went further than mere recognition. A major manufacturer of telecommunications products decided to purchase the company from Duane Treiber, who chose to retire in January 2001. They were looking to expand their moldmaking capacity and felt Custom Mold & Design was the best they could buy.”

Then came the bad news. Shortly after the purchase, the bottom fell out of the telecommunications industry. “Before this bubble burst, we had just sent out letters to all of our customers stating that Custom Mold & Design had become a captive shop and would no longer build molds on a contract basis,” Engineering Manager Dave Parks recalls. “In other words, we were forced to cut ties with all existing customers. Suddenly, our new owner was the only customer that we had, and they were now not in any position to buy new molds.”

Late in 2002, it looked like the auctioneer might be writing the last chapter in the story of Custom Mold & Design as the new owner decided to liquidate the company. But Walt Halberg stepped in and asked for the opportunity to see if a new owner could be found that might be able to keep the company in business.

“Ray Newkirk, who was a former co-worker of Duane Treiber and a long-time acquaintance of Walt, was contacted,” Parks says. “The purchase was made in January 2003; and the long struggle to breathe new life into Custom Mold & Design was underway. Walt Halberg and I contacted every customer Custom Mold & Design had ever worked with in the past, to re-enter the contract mold manufacturing business. The loyal customers returned thanks to the past performance that had been demonstrated.”

Today, the 35-employee company occupies a 22,000-square foot facility and is committed to continuous improvement—whether it be skill sets, equipment or its facility. “We feel more strongly than ever that this company is team-driven to succeed,” Halberg emphasizes. “We have designed and manufactured more than 5,000 molds since the company was founded.” The combined experience of the company’s engineers and moldmakers is in excess of 550 years and the average employee has 20 plus years at Custom Mold & Design.

Machining/Software Combo

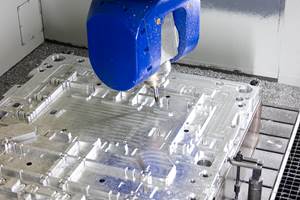

The company credits the most modern equipment combined with the latest in software as a major factor in the company’s continued success. “When we made the decision to buy a Yasda CNC hard milling machining center and Cam-Tool software, we purchased the best quality possible,” Casey elaborates. “We also recently bought a new Mitsubishi EDM sinker to achieve better finishes and tighter geometry on smaller parts. Our reputation is based on our quality and our company’s mission is to listen and communicate in order to meet the requirements and demands of each and every one.”

Custom Mold & Design spares no expense when it comes to equipping the shop floor. “We buy the best to assure the best quality possible, no matter what the job,” Casey notes. “On the surface, it may seem that the initial cost of some of this equipment is high, but the bottom line is the overall value that it provides. If we can eliminate fitting or polishing, we save hours. If the people running the machine know that it will achieve the tolerances we need every time, they spend less time creeping up on dimensions. In the final analysis, this high-end equipment is the most cost-effective solution for our customers and our company.”

Cultivating Talent

One of the company’s bigger hurdles is attracting new talent—a universal industry problem. “Some of the ways we compete for the best people are having the best equipment and facility for them to work with, a team environment, and a commitment to continuous improvement,” Casey says. “Custom Mold & Design has always been committed to the training of young people. Duane Treiber and Ray Newkirk are both Dunwoody College of Technology (Minneapolis, MN) alumni. Ray currently serves on the Board of Trustees for the college. Dunwoody is one of very few technical colleges that are expanding their machine tool programs in the U.S.”

The company also doesn’t ignore the business side of moldmaking. “The management team utilizes strategic planning on a regular basis to create a vision for the future as well as the disciplines and strategies to get there,” Casey explains. “We take the planning and organization side of the business very seriously as these areas are where some of the biggest gains can be made.”

Plan for Growth

Casey notes that the company’s R&D efforts are focused on expanding its hard milling capacity and technologies for the benefit of its customers. “We are working closely with our cutting tool supplier, machine supplier and software supplier as a team, to document the various speeds, feeds, chip loads, cutters and coatings, to achieve the best finish, tolerance and quality possible,” he states. “We serve our customers with the best technical knowledge and we feel our suppliers are a great resource for our team to achieve our goals.

“We pride ourselves on meeting the ever-changing needs of our customers,” Casey continues. “They rely on us for advice in all phases of their molding requirements. We typically participate in the part design as well as taking full responsibility for the mold design and manufacture—including mold qualification. The molded part costs are highly influenced by the design of the mold as well as the design of the product being manufactured. Our highly experienced engineers and moldmakers are capable of providing the creative input necessary to make the best possible decisions. Attention to detail and the manufacturing discipline employed create precision components that provide our customers the benefits of interchangeability of components. These benefits provide lower maintenance costs, longer mold life, and more consistent product quality.”

Related Content

In "Hybrid" FIM Process, 3D Printing Complements Injection Molding

Alpine Advanced Materials used a desktop 3D printer and the freeform injection molding process to reduce prototype tooling production time and cost for its customers.

Read MoreHow to Harness 3D Scanning for Mold Tool Repairs

3D scanning supports the repair of molds with no history, drawings or design files.

Read MoreSpeed, Productivity Gains and High Uptime Ease Decision for Second Five-Axis Machine

Byrne Tool + Design reduced setups and gained speed and productivity thanks to fast, accurate and compact five-axis CNC machining centers.

Read MoreTrue Five-Axis Machine Yields More Throughput, Greater Productivity

CDM Tool & Mfg. Co. LLC increased shop capacity thanks to a versatile high-speed/high-accuracy five-axis Fooke mill capable of cutting very large workpieces quickly and accurately with fewer setups.

Read MoreRead Next

Tech Tool & Mold, Inc.: Staying Focused

This moldmaker’s firm belief in continuous education for its employees combined with advanced training and cutting-edge technologies increases total delivered value of its products.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More