Let’s start off the fall season right with MoldMaking Technology’s monthly product/service roundup. The highlighted companies and pieces found below provide a brief glimpse into what you might see in MMT’s October 2021 print issue. The focus is mold components and includes new/proven technologies from core pins, to an ante-chamber bush and more.

Never seen some of these before? We publish products/services on a daily basis, so browse our “New Tech” section on the homepage of our website, or find them via the website search bar for a more streamlined approach. Follow each title link for the full product post.

In case you missed it, check out the September product roundup.

Mold Components

Mechanical cycle counters A5730HT and A57300HT, which can be used wherever there is a need to monitor process data, mark a further addition to the Hasco counter range. As a high-temperature version, the cycle counters can be used at temperatures of up to 200°C.

Potential for left- and right-hand operation provides for a high level of flexibility in assembly. The cycle counters can be mounted both on the fixed and the moving mold plate.

The high-temperature cycle counters feature a seven-digit mechanical, non-resettable counter, are quick and easy to mount, completely maintenance-free and independent of the power supply. The reliable counting with each injection molding cycle guarantees optimum process data control.

PFA Inc.’s new 70 series mini hydraulic locking cylinder—part of the KOR- LOK side-action system product line—features preloading capacity in a small cylinder footprint. According to the company, the product’s main advantages are high output force with locked in preload. The mini’s 8,000 lbs of preload activates force in a new narrow format, enabling multiple small cores to nest together and time independently.

Progressive Components introduces a new angle pin holder engineered to simplify the installation and removal of angle pins.

For the mold builder, Progressive’s angle pin holder is designed to avoid angled machining, and on large A plates, it eliminates the need for long angle pins and long bored holes. For the molder, removal of broken angle pins from the parting line is said to be simple, and unlike other approaches, does not require the mold to be removed from the press.

DME introduces its advanced solution to molding threads and undercuts with its new S-Core Collapsible Cores. The S-Core is a dynamic design that can be produced in six, eight or 12 segments, enabling parts to be produced as small as 6 mm and as large as 400 mm. The length and depth of the part feature dictates the number of segments required to release the undercut.

Smith Enterprises’ custom core pins expanded DedTru systems grinding capacity with dimensional repeatability, accurate tolerances and concentricity within 0.001-0.0002. Ideal for medical and electronic applications, the core pins are suited for high-cavitation molds running 24/7.

CUMSA is introducing a new component to work with its current line of external ejection systems, that control the plates during the mold opening and closing sequence. This new product is an adapter (EB), also called an external fixing, which now offers a standard component solution without the need of a homemade adapter.

Meusburger US presents its cooled ante-chamber bush, which ensures optimal cooling in the gate point. Ante-chamber bushes are used in hot runner nozzles for providing the required nozzle shape in the cavity plate. They help to quickly restore the gate point quality in applications with abrasive plastics.

Crafts Technology engineers and manufactures CraftAlloy tungsten carbide core pins, inserts, bushings and other injection mold tooling.

According to the company, CraftAlloy tooling is more rigid than other mold tooling materials on the market; it reduces core shift and deflection, which reportedly allows for the highest possible process capability (Cpk) with injection molded parts.

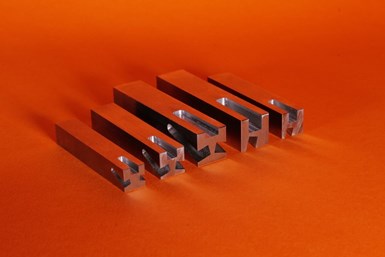

The Almo company manufactures and supplies edge gate cutting pins used to separate the runner and gate on the edge of the plastic molding during mold opening.

Almo has recently introduced a range of square cutting pins, which can be modified to the plastic moldings’ edge profile.

Established in 1990, Romeo, Michigan-based Mac-Mold Base has more than 30 years of experience in the mold manufacture industry. The company specializes in 3D machining, and can handle large plate capacity. The use of multi-axis machining centers and its complete in-house support services enable Mac-Mold Base to streamline its processes and ensure on-time delivery.

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)