Are you a fan of MoldMaking Technology’s monthly print product/service roundups? Then you’ve come to the right place.

In order to acknowledge all of the amazing content we receive on a weekly basis, MMT has compiled all of its digital-only product/service items below for this month to keep your shop engaged in the latest and greatest products that are being offered in the moldmaking industry.

Missing out on the new and proven technologies and services we showcase in our print issues? Head on over here for the June issue roundup, or visit the “Magazine” tab.

Mold maintenance, repair and surface treatment and miscellaneous products in the mold component and software categories are highlighted below:

Mold Maintenance, Repair and Surface Treatment

Trumpf Inc. has released its first automated arc welding system, the TruArc Weld 1000. The system comes with a collaborative robot (cobot) which, once manually guided over the part by the operator, automatically creates the weld program, eliminating reliance on values from an offline source or entering positional data manually. CE-compliant and approved by TÜV Austria, the TruArc Weld 1000 is said to meet the highest safety standards.

Slide Products Inc. presents X-EMPT, a mold cleaner that contains only

EPA-exempt VOC compounds, guaranteeing air quality regulation compliance for plastic processors. The cleaner surpasses California Air Resource Board (CARB) standards, and like Slide’s other products, has no chlorinated solvents.

According to Slide Products President Michael Muth, X-EMPT is specifically designed to clean molds that have cooled to temperatures ranging from 32-200ºF (0-149ºC).

Grieve Corp.’s 500°F (260°C) top-loading, electrically heated oven can be used for heat treating parts at the customer’s facility. Workspace dimensions measure 96” width x 20” diameter x 20” height. Eighteen KW are installed in Incoloy heating elements, and a 2 HP blower provides back-to-front airflow to the workload.

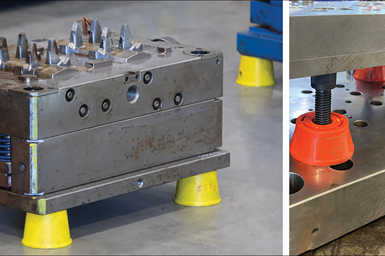

From molds on the floor to tools on the bench, Progressive Components’ new RhinoFeet are said to be a simple, safe and efficient solution for elevating and storing heavy items within the shop. This makes for a safer, cleaner approach when used under molds, eliminates the trip hazard of wood and skids strewn about the plant and improves 5S standards within the shop.

(See also: “Think Safety: Eliminate Hazards Throughout the Shop”).

Mold Cleaner Plus Degreaser 4 is the next generation of Slide Products’ most popular mold cleaner. According to the company, the product contains no chlorinated solvents—making it better for workers and more environmentally friendly—and is less expensive, enabling more low-cost mold maintenance.

Lifting and lashing technology supplier RUD Ketten Rieger & Dietz GmbH u. Co. KG has launched new variants of the RUD ACP-TURNADO to achieve heavier loads up to 16 tons for higher working load limits (WLLs) and expand its application range. The intelligent-centric lifting point automatically rotates in the load direction when the load is lifted, preventing the lift bail from coming to a dangerous standstill and avoiding other associated high shear forces. This eliminates sagging and sudden reversal of the suspension bail, and enables a higher level of safety when handling load, crane and load-handling equipment.

Miscellaneous (Software, Mold Components)

Progressive Components introduces the C-Series UniLifter mold undercut release system, which is able to compensate for misaligned mold ejector plates.

The new C-Gib features a cylindrical surface that the C-Coupling travels along when ejecting a molded undercut. Said to be able to self-adjust in both the X- and Y-axis, smooth travel along the black-nitrided surfaces reportedly prevent stress and wear between core blades and mold inserts, while providing a surface against molding pressure versus the single point contact of dowel pins or tooling balls.

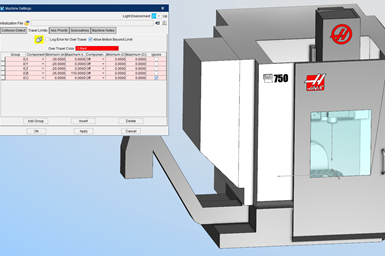

CGTech has announced that its Vericut software for CNC machine simulations can now read in Geometry Description Markup Language (GDML) files with a new 3DLive Interface. GDML is an application-independent geometry description format based on XML.

3DLive is available in MachiningCloud for products that require kinematics such as machine tools and workholding devices. MachiningCloud has traditionally been known for the ability to provide 3D models of cutting tools for use in Vericut and other related CAD/CAM and simulation software.

FactoryFix is an online platform that matches vetted manufacturing workers with companies seeking specific skill sets. Unlike conventional online job boards or recruiting services, FactoryFix reportedly provides additional value to manufacturers beyond simply suggesting candidates, such as providing a personalized career coaching experience to enhance and coordinate professional development. The platform’s technological advancements are said to also accelerate speed-to-interview and hire, translating to a lower cost per hire and access to a vast network of qualified candidates.

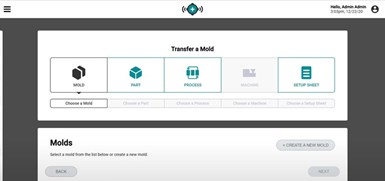

RJG’s injection mold networking software, The Hub, now has a new application available: The Hub for Mold Transfer.

The Hub for Mold Transfer is said to permit an easy transfer of molds by automatically generating machine-specific setup sheets, recommending compatible machines and providing a database to store and share part, mold and machine documentation across the organization.

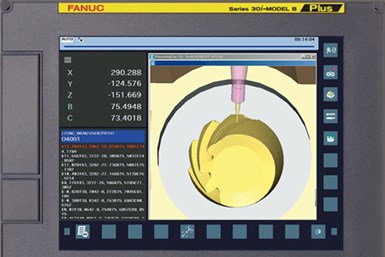

Automation solutions provider FANUC America and CNC Software, CAM systems provider of Mastercam, introduce a new post processor designed to optimize FANUC CNC five-axis capabilities. The new post processor reportedly enables advanced machine tool operators to reduce their cycle times while boosting part accuracy, particularly for CAD/CAM-generated five-axis simultaneous contouring part processes. Further, machine tools will be able to produce parts—modeled in the CAD system—more precisely.