With spring right around the corner, MoldMaking Technology is highlighting the latest hot runner and mold component technologies and services being offered to the moldmaking industry. Below is a sneak-peak of some prominent companies that offer products in these categories and appear in the upcoming April 2021 issue, including Mold-Masters, Agathon Machine Tools, Technoject Machinery, Thermoplay, CUMSA, Husky and much more.

MMT publishs new/proven products/services on a daily basis, so browse our “New Tech” section on the homepage of our website, or find them via the website search bar. Follow each title link below for the full product post.

Find March’s print (which covered extensive cutting tool offerings) or digital-only technology roundups here.

Hot Runners

The Equatemp Dual Zone Sprue Bushing from Melt Design is a robust, internally heated hot sprue bushing with two zones that are said to provide ultimate temperature control and uniformity. Designed for applications that demand higher precision, this bushing is ideal for use in the automotive and medical industry.

The Dual Zone Hot Sprue Bushing offers dual heaters for independent adjustments. It is designed to retrofit cold sprue bushings and ideal for high-temperature engineering resins. The thermocouple is replaceable if needed.

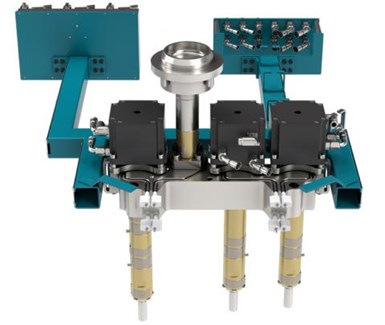

Mold-Masters’ new, second-generation SeVG+ (Servo Electric Valve Gate) motor is a compact, direct drive design that has reduced stack height by 48% (at an installed height of 114 mm), simplifies mold design and offers superior process control for demanding applications.

With a footprint of 108 x 108 mm, the servo motor is interchangeable with Mold-Masters’ hydraulic actuator for added flexibility. The design itself has been made compatible with the company’s full range of valve pin diameters (2.0-9.5 mm) and incorporates integrated water-cooling channels for high-temperature applications. It is also well suited with molds utilizing magnetic clamps.

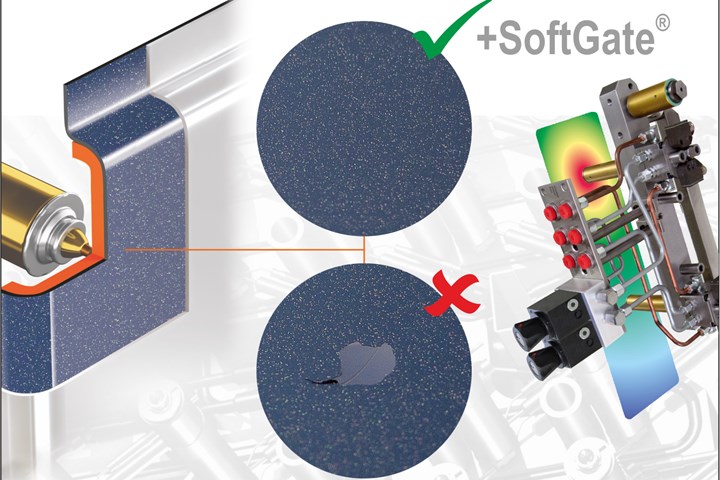

Several years ago, INCOE recognized the challenge of direct valve gating a part while overmolding film or fabric in mold decorating. Using control technology, the company’s SoftGate Velocity VG pin enables these applications to be direct gated. This allows for the “gentle” flow of plastic into the cavity, eliminating blemishes that can occur with uncontrolled flow.

Mastip recently launches the latest development in its Guided Valve Gate Tip range (GVG5) with a focus on durability, efficiency and long-term value. Delivering precise valve pin alignment for cylindrical gates, the GVG5 tip aligns the valve pin before shutting off in the gate to improve gate life.

Available in both thermal and valve gate options, the GVG5 tip range is engineered specifically to process highly filled engineering polymers with fillers like glass or carbon fiber, and talc. Mastip Guided Valve Gate Tips are constructed from tungsten carbide with a TIN coating.

Husky Injection Molding Systems presents the UltraShotTM Injection System, a next-generation melt delivery and control system that is said to eliminate traditional injection molding process deficiencies and achieve risk-free scalability, improved capability and overall part design freedom.

UltraShotTM Injection System’s identical system behavior for each injection circuit provides process condition consistency with cavitation scaling. A predictable process from pilot to high cavitation—scalable to 128 cavities—enables producers to maximize cavitation without negative performance on balance or shot-to-shot variation. Accelerated prototype to high cavitation production qualification further increases speed-to-market.

Thermoplay S.P.A. presents its D-bushing component for hot runner nozzles, a solution for high cavitation molds with frequent version changes. Meant to preserve gate point quality and prevent plastics wear in nozzle components, the company’s gate bushing is said to improve safety, stability and reliability during the molding process and consume less energy.

Designed for Thermoplay’s TF nozzles, D-Bushing is equipped with a double sealing ring on the external diameter to protect the injection system—the tips in particular—from thermoplastics leakage, and preserve internal components from wear and potential damage during assembly and disassembly operations, and allows for more frequent changes to the mold version.

Heitec Hot Runner Systems’ products, available in North America through Technoject Machinery, has introduced a new Starline Edge Gate Nozzle, a short and compact component made for short installation height. It is suitable for small tonnage injection molding machines and for miniature article weights where residence times are critical. The nozzle’s height makes designing into small molds with limited mold height possible.

Hotset America’s Z-System is an efficient temperature control solution for injection-molded tools, which prevents unfavorable surface flaws, such as weld lines or dullness. Forming tools or cavities can be heated and cooled rapidly in a targeted manner, both partially and in short cycles. The Z-system also boasts a heating rate of 60 K/s at the tool wall.

Plastixs, a U.S. and Canadian distributor for AIRTECT, introduces the AIRTECT Plastic Leak Alarm System. Offered in a number of configurations depending on the application and how the injection molder operates, the system detects machine nozzle and hot runner leaks early.

A small amount of air moves through robust, 1.6-2-mm stainless steel tubes (2-3 psi, <0.01 cfm per tube) placed in the hot runner. A built-in pressure differential sensor sets off an alarm whenever airflow on any tube is blocked. A small length of high-temperature silicone tube can also be added to the stainless steel tube for increased sensitivity. Plastixs notes that this system enables the ability to perform mold repair and return the mold back to service within 1-2 days.

The S Series Cylinder by HRSflow for hot runner systems is a compact solution that enables reduced pitch and is suitable for technical materials.

With its compact shape, lowering plate thickness is now possible. A reduced width further enables a minimum nozzle pitch of 37 mm (1.46 in.). HRSflow offers two layout versions: The basic version offers a cutout height of 65 mm (2.56 in.), and the adjustable version, with a needle position that can be adjusted ± 1 mm, offers a cutout height of 73 mm (2.87 in.).

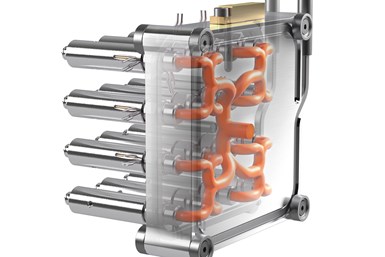

Hasco’s Steamrunner is the culmination of the company’s move into additive manufacturing for hot runner manifolds, which it first started back in 2016.

The company says that as an additively manufactured hot running manifold, the Steamrunner offers moldmakers and injection molders unprecedented freedom in design. Using this technology, manufacturers can configure flow channels with optimum rheological layouts, avoiding sharp edges and areas with poor flow.

Mold Components

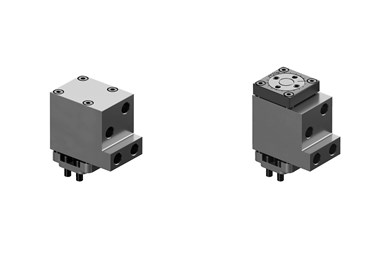

Now offered in a Ø24-mm diameter, the CUMSA Sprue Adjuster (SA) family has been made available in 4 sizes. As with its smaller SA types, CUMSA says these sprue adjusters are offered in two versions—SA240022 and SA240822—which are suitable for molded parts which require larger runner gates, and are compatible with larger nozzle diameters up to 22 mm.

A sprue adjuster is to be set manually from the mold parting line when the mold is open, by turning the cylindrical body, to open or close them, as necessary.

Extension of i-mold’s tunnel gate insert TG Series range with curved feed channels further supports compact injection mold designs for diverse application tasks.

Customers can choose between three sizes for shot weights up to 35 g (type I), 120 g (type 2) and 1000 g (type 3), as well as between three (low, medium, high) feed channel outlet levels. With these nine different configurations it is possible to optimize the sprue-to-molding volume ratio in applications involving large contour steps, moldings with a peripheral rim, or interior contours located above the mold parting line.

Edro Engineering and Specialty Steels, Inc. showcases its specialization in the manufacture of high-cavitation custom mold bases, designed to demonstrate precision alignment and long-lasting performance. Edro primarily produces high-cavitation stripper molds, stack molds, super structures, spin-stack molds and hot runner bases, as well as auto unwind and runnerless mold bases to exacting tolerances.

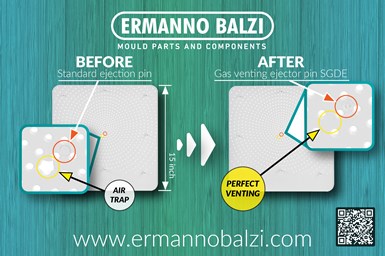

To help resolve common effects that result from poor cavity venting, Ermanno Balzi showcases its Internal Dynamic Valves SGD and ejectors SGDE, which, due to a larger venting surface and punctual positioning of the valve, are said to overcome most performance limitations common to standard venting options. In addition to achieving better quality parts and reducing scrap during production, the company says its dynamic valves also enable reduction of injection pressure and injection time.

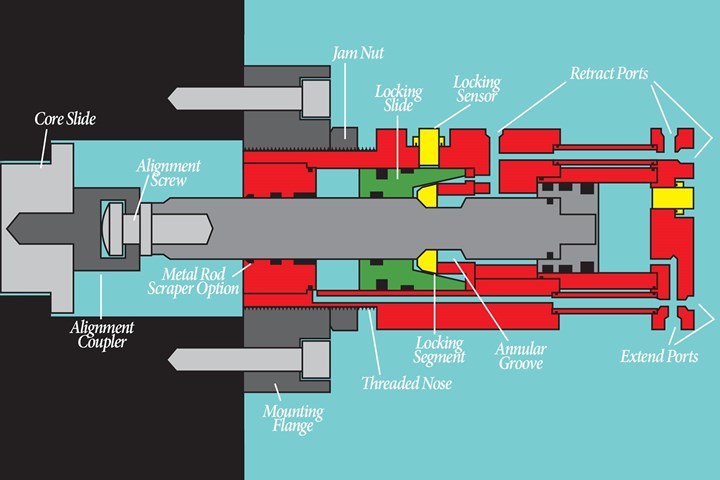

PFA Inc. provides a complete cylinder preloading and locking system for movable cores and core pulls on injection molds to help molders improve mold performance with off-the-shelf solutions, assisting in high-quality part production in a smaller mold footprint.

The PFA Kor-Lok side action system is said to have performance enhancements beyond standard hydraulic and locking cylinder systems with its ability to preload slides to high forces and maintain the force at 0 psi, a feature different from many traditional spring-locking, hydraulic-activated solutions which often do not lock, preload or maintain force without hydraulics.

DME’s proprietary Accualign Lifter possesses an improved design to help address current lifter shortfalls for optimized molding productivity, including potential misalignment during the molding process, which can often lead to costly, unplanned production shutdowns, part quality problems and possibly catastrophic damage to the mold surface itself.

According to DME, the Accualign lifter features a multi-axis self-adjustment system which compensates for misalignment.

eMoldino presents the next-generation IoT mold sensors and a mobile application compatible with its analytics platform. Through this, eMoldino anticipates improvements in quality, scope and reach for its tooling digitization solution. With boosted capability for predictive analysis, eMoldino says users can expect more accurate reports regarding digital mold management. This includes additional reports and predictive models on quality risk assessment, quality assurance, process change detection and mold life cycle.

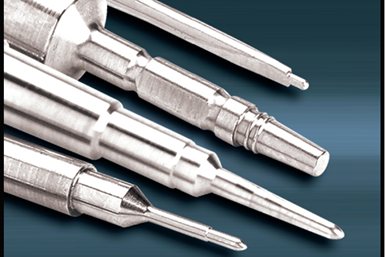

Smith Enterprises’ custom core pins expand DedTru machining systems’ grinding capacity with dimensional repeatability and accurate tolerances and concentricity within 0.001 and 0.0002 in. Ideal for medical and electronic applications, the core pins are suited for high-cavitation molds running 24/7. Consistent dimension control enables simple core pin replacement at required maintenance intervals.

SelfLube’s aluminum bronze T-Slides are an upgrade from the steel T-Slides used extensively in slide assemblies. Made in the same dimensions as its steel counterpart, the aluminum bronze component—a one-part slide solution designed to run in a T-slot cut in a base plate—enables a simple swap-out, and, as a less complex part overall, is said to be easier to transition than changing the base.

According to the company, in a typical slide assembly, a steel angle pin is often used to control movement of the T-Slide. However, the use of an aluminum bronze T-Slide neatly eliminates both instances of steel sliding against steel.

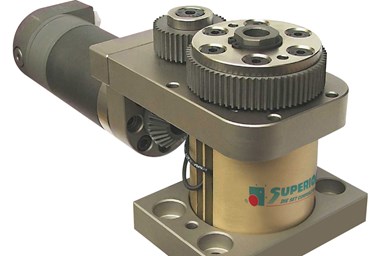

Superior Die Set’s Threadformer unscrewing devices alleviates the difficult task of unscrewing molds without compromising the part by rotating the core holder in and out of the mold via a compact, and powerful hydraulic motor. To guarantee a precise thread start position, the core holder runs against a fixed stop, which is typically the mold base.

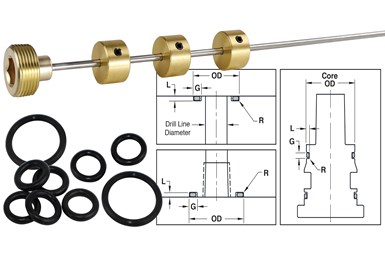

Progressive Components’ O-Rings addition provides mold designers with more route cooling line options within their tools, and an industry-standard that includes the machine groove detail. With this standardization, the subsequent replacement during mold maintenance has been made easier to locate and purchase by mold maintenance managers. O-Rings are available for both face sealing and core sealing applications and are offered in two material options: Buna-N for temperatures up to 225°F and Viton for temperatures up to 400°F. Sizes range from 0.566 OD to 4.872 OD, and cross-sections of 1/16th, 3/32nd and 1/8th.

Agathon Machine Tools now offers its new Guide System Plus, which performs guiding and centering tasks for the precise positioning of mold halves/mold component using only one system. Ideal for cleanroom, high-precision, micro-injection molding and high-temperature applications, the system is said to increase planning reliability in production, boost productivity and reduce overall production costs.

By design, each bushing and pillar comes with a freely positioned retaining ring that is adjustable to various plate thicknesses for improved adaptability when repairing or converting tools to newer guide systems. One component can be used in multiple designs.

Meusburger’s new clamping configurator tool enables customers to order plates they need to machine with the fitting holes for the clamping bolts of their zero clamping system already pre-drilled, reducing machine setup time, and eliminating a step in the mold plate manufacturing process. The company is offering this service for the P standard and P special plates range.

Machining sizes of the fitting holes are already preset, Meusburger notes, but certain parameters such as thread or counterbore depth can still be changed within defined limits.