For the month of March, MoldMaking Technology focused on cutting tool products. Below is a sneak-peak of some prominent companies that offer products in this category and appear in the upcoming March 2021 issue, including Tungaloy, Walter, Seco Tools, Big Kaiser and more.

MMT publishs new/proven products/services on a daily basis, so browse our “New Tech” section on the homepage of our website, or find them via the website search bar. Follow each title link below for the full product post.

View February’s print or digital-only technology roundup.

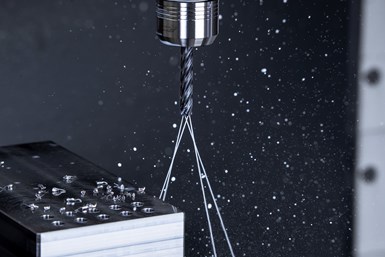

Ceratizit USA Inc. features the WTX High-Feed Drill, what the company says is the first of its kind on the market. The drill offers customers four effective cutting edges for increased precision, productivity and service life.

The innovative pyramid geometry of the WTX ensures aggressive and precise drilling performance, achieving positioning accuracy of 0.03 mm and excellent centering properties. Higher levels of drilling quality, hole tolerance, surface finish and positioning accuracy increase component quality, reducing potential reworking and low burr formation.

Walter USA enables wider versatility with an expanded range of tolerances for its popular TC117/TC217 Advance tap product line.

Reducing the number of taps needed, the new oversized blind and through-hole taps deliver high threading productivity in a wide range of different materials. The TC117 (blind-hole) and TC217 (through-hole) taps tackle material ranging from steel and stainless to cast iron and non-ferrous materials (ISO material groups P, M, K and N), and materials with hardness up to 40 Rc (370 HB).

Seco Tools presents the Turbo 16 square shoulder cutter to its Turbo portfolio to acknowledge secure processes and long tool life, two characteristics the company says that have not experienced high importance in the cutting tools category.

With optimized features, the cutter generates exceptional tool performance across a broad range of applications and materials. A smooth cutting action and low cutting forces reduces power consumption and tool wear, boosting tool life by up to 130%.

Tungaloy America Inc. introduces a new VFM-style milling head to the TungMeister series of exchangeable-head end mill systems to enable face milling operations.

According to the company, TungMeister is designed to reduce a significant amount of tool changeover time through its ability to replace used heads instead of an entire tool. Short setup time is reduced to one tenth of the time it would typically take to replace solid carbide end mills for maximum productivity and cost effectiveness.

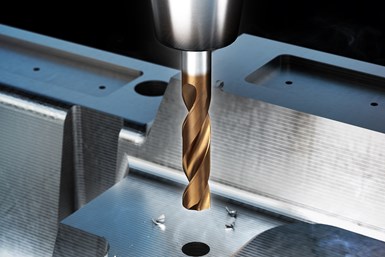

YG-1 Tool Co. has beefed up its Dream Drills lineup with the announcement of its new Dream Drills Pro line optimized for machining in steel and cast iron.

The drill line are made with micrograin carbide for exceptional core strength and longer tool life. They also feature YG-1’s wave-shaped cutting edge to reduce cutting forces, and an advanced, wide-flute design optimized for faster, reliable chip evacuation. A self-centering 140° point angle reduces torque and extends tool life.

Allied Machine and Engineering has expanded its boring line with the Wohlhaupter VolCut insert holder. The rough boring system removes large volumes of material at high speeds and light feed rates in just one cut.

VolCut combines the modularity of the Wohlhaupter MVS connection with Allied Machine and Engineering’s large-diameter holemaking solution. The company says this combination offers increased material removal and excellent chip control at greater depths for large-diameter applications.

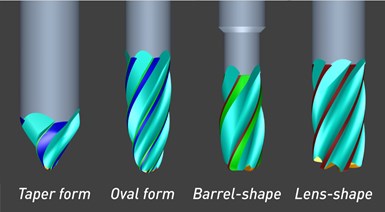

ANCA Inc. showcases the support of the barrel shape ballnose (BSB) tool type in its up-to-the-minute ToolRoom RN34 software for machining. The software’s latest enhancement also comes with revamped double corner radius (DCR) endmills, and support four tool types, including taper form, barrel, oval and lens shapes, which are predominately used in die mold, aerospace and general machining applications.

With the support of these forms, ANCA says, the ability to create endmills with a larger radius edge has been made possible, thus permitting greater step over increments, which in turn improve productivity, longer tool life, faster cycle times and improved surface finish.

Paul Horn (USA and Mexico) have recently added several cutting tool products to its offerings, including the System Mini tool system for threadcutting by turning; its DDHM/DSFF tools for carbide and core drilling; and a range expansion for its M310, 383 and M101 slot milling tools. All products offer improved stability and higher performance.

Big Kaiser Precision Tooling showcases the Noventa from Sphinx, the newest addition to its milling cutter lineup. The Noventa is ideal for 90° front-and-back chamfering, and deburring holes up to 4xD.

According to Big Kaiser, the Noventa from Sphinx can transform the tedious, time-consuming process of chamfering the entry and exit of 0.80mm to 6.00mm holes using an innovative geometry that improves cycle time, tool life and surface quality.

Dormer Pramet’s long-time Precision Twist Drill brand continues to illustrate its quality and consistency with the HX series of High-Speed Steel jobber drills, which offers a purple/bronze oxide finish for increased wear resistance.

According to the company, the series combining the toughness of HSS substrate with a 135° split point design, which reduces thrust requirements and eliminates drill “walking” while providing greater strength and rigidity than general purpose drills.

Thinbit, manufactured by Kaiser Tool Company Inc., introduces its angled round toolholders, which are designed for CNC, conventional and end working positions on Swiss screw machines.

The angled round toolholders position the insert at 30°, 45° or 60° angles for reliefs, undercuts and angled OD and face grooves. Round shank sizes are available in diameters of ½, 5/8, ¾, and 1 in. and 20 mm and 25 mm.

RobbJack unveils two new cutting tool-based products, the through-coolant slitting saw arbor and ER-style collet integrated saw arbor.

According to the company, the through-coolant slitting saw arbor will achieve faster and more consistent speeds and feeds, and extend tool life.

RobbJack’s solid, ER-style saw arbors have precision ground tapers and saw journals for unparalleled ease of use and advanced productivity.

Machine Metrics showcases the Predictive Tooling Calculator which diagnoses, predicts and avoids tool damage and quality issues—such as subtle anomalies in machine load, torque, acceleration and spindle speed—before it happens. This, in turn, can also reduce production costs, from machine downtime, damaged tools or scrapped parts.

Issue variables are determined by a specific list of questions the calculator provides.

.png;maxWidth=300;quality=90)