Technology for Improving Five-Axis Capability

With five-axis in place, it’s time to look at the advantages of investing in new software technology to improve processes, new approaches to part setup and the factors to consider before your purchase.

If you have already embraced five-axis machining, the following article will provide information about new software technology developed to improve processes and illustrate examples of new approaches to part setup that might make your shop more productive. If you haven’t taken the five-axis leap, this article will illuminate the advantages of investing in such technology and things to consider before your purchase.

Measure Twice. Cut Once.

Even though it is considered the carpenter’s mantra, the gist of the saying, “Measure twice. Cut once,” is applicable—spend more time thinking, preparing and planning instead of rushing to make chips.

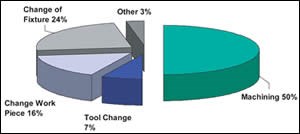

Sometimes the most inexpensive way to find productivity is to take the time to evaluate each job. Chart 1 shows that 24 percent of a job’s capacity is spent on fixturing. To increase efficiency, some shops try to minimize time spent on fixturing by using a row of vises and then flipping each part into the next vise. Other shops opt for the more efficient index table, but the operator is still required to handle the part to refixture it. The key to peak efficiency is finding the sweet spot—at what number of parts is the investment in a palette changing system worthwhile.

Also, evaluating whether it’s more effective to machine a part from a billet versus castings can increase productivity—one customer found machining from a billet not only saved time and money, but gave them more control over deliverables. By machining the part from a billet, the customer eliminated delays due to leadtimes for the castings and saved time/money on storing the castings.

Obviously, upgrading your equipment can provide greater efficiency.

The trick is to figure out how quickly you will see the return on your investment. One customer analyzed his primary part numbers and discovered that upgrading to a machine with faster feedrates and more torque would cut cycle time in half on his biggest job—from three hours to one hour and 30 minutes.

Technology Solution: Software Designed to Solve Problems

Beyond the machine specifications, technology benefits reside in the control’s software—features that were designed to solve problems and help you be more efficient.

Multiple Part-Zero Setups

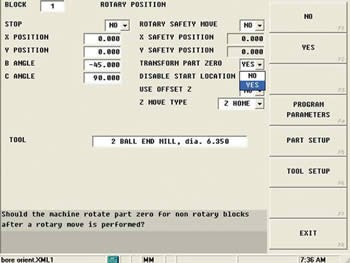

For instance, even an uncomplicated part that is five-sided requires multiple part-zero setups. A software feature called transform part zero (see Figure 1) reduces setup time and eliminates the hassle of setting up part zero five times. The technology does the work so you can start making chips. You just need to locate one part zero and the remaining part zero locations can be defined as incremental measurements from the original location. Additionally, you can still program the geometry on each of the sides if you’re programming in an XY plane.

Redundancy in Posting a Five-Axis Program

Each time you refixture, you have to waste valuable time re-entering the distance from part zero to the center lines of rotation and then repost the program. If your control has a software feature such as tool center point management, you only have to post the program once and machine the part—no matter where it is in relation to the center lines of rotation on the machine.

Tool center point management solves the problem for CAM software. The CAM programmer generates the toolpath based on the part model’s zero location. Therefore, you can post the program independent of where the stock is fixtured on the table—a substantial time saver for a five-axis part.

Complex and Difficult Post Processors

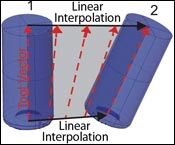

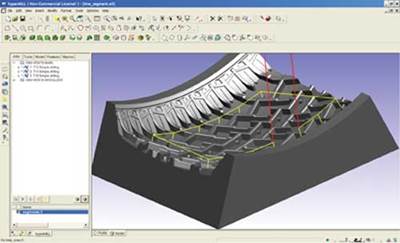

CAM systems generally use tool vectors to generate the toolpath. To make programs independent of the machine’s rotary configuration and to simplify the post processor, there is a tool vector input control software feature for five-axis machining centers (see Figure 2). This feature lets you specify the tool tip location relative to the workpiece and the tool axis vector instead of using address letters to specify the B and C axes angles. Executing the program is much faster because the post doesn’t need the machine configuration and the centerline of the rotary axes.

Marks on the Part

Simultaneous five-axis toolpaths can result in odd looping rotary moves that leave marks on the part when the program is interpolated by the machine’s control. One solution is a feature called toolpath linearization, which is specific to five-axis, G-code programs. It eliminates the many line segments in the form of XYZBC moves that a CAM system uses to create a smooth part. With toolpath linearization, the tool tip and tool vector can be interpolated between tool positions with respect to the workpiece even with the tool and part rotating inside the machine (see Figures 3ab).

Reposting to Adjust for Tool Wear on 3-D Surfaces

For 3-D surfaces, you cut off of the tool centerline to get a better surface finish. Because you have to adjust the tool diameter for wear, you are sometimes forced to repost the program. A software feature called 3-D tool compensation eliminates the need to repost the part program because the control’s software compensates for the tool geometry (see Figure 4 for visual explanation).

Summary

In this competitive environment with skilled labor shortages and demanding schedules for complex parts, investing in machine tools with the latest technology is the most efficient way to see measurable productivity gains.

Related Content

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreHow to Produce More Accurate Molds and Reduce Rework

Patented micro-milling process for manufacturing steel plate flat and parallel helps mold builders shorten mold build times and increase accuracy.

Read MoreRead Next

Improve Shop Competitiveness With Five-Axis Capability

The key to keeping work local, while still remaining profitable, is a willingness to evaluate and dramatically alter your shop’s processes by investing in new technology.

Read MoreFive-Axis Machining: What Are The Benefits and How Can You Achieve this Capability?

The alternative you choose to achieve five-axis machining benefits will be application driven and can have a significant effect on your bottom line.

Read MoreMaximizing Machine Tool Potential with CAM Software

Identifying specific items where CAM software can take advantage of machine capabilities to the benefit of the user and maximize exploitation of milling machine potential.

Read More