Tech Trends: Software Selections

Take a glance at latest software releases and product updates from MoldMaking Technology suppliers, such as SURFCAM from Hexagon Manufacturing Intelligence’s Production Software, Siemens Digital Industries Software and Kubotek3D.

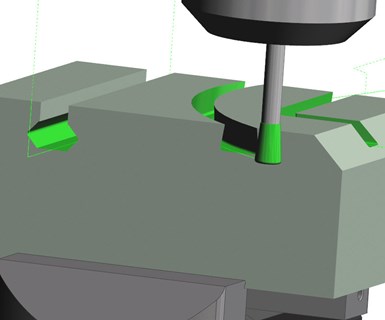

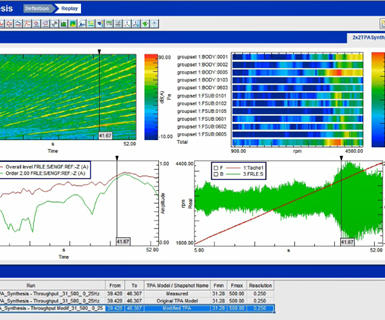

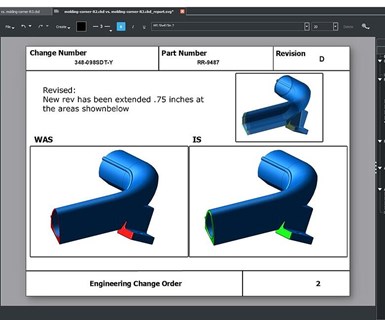

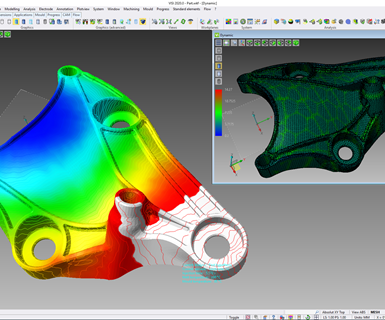

Design and engineering is essential to building a better and more cost-effective mold with shorter leadtimes. A variety of software is available to help overcome the daily challenges faced with data, quoting, designing and programming, so why not take a glance at some of the latest product offerings from some of MoldMaking Technology’s supplier companies? From giving greater flexibility to processes, access to technical guides and application-based materials, to updates and releases that focus on specific needs for machinist programmers, these selections offer a wide range of solutions to benefit your machining!

Interested in More?

Keep in the know about recent mold manufacturing updates with a review of recent products and services announcements from MoldMaking Technology’s comprehensive list of supplier companies.

Browse our entire database of moldmaking products in the products section, or check out our Software Zone Index. You can browse to stay updated on the latest product offerings, or search for specific product information based on categories.

Related Content

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreTips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreFour Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read MoreTolerancing in Mold Design, Part 1: Understanding the Issues of Conventional Bilateral Tolerancing

Mold designers must understand the location, orientation and form limitations of conventional tolerancing before changing to another dimensioning system.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More