Keep in the know about recent mold manufacturing with a review of recent products and services announcements from MoldMaking Technology’s comprehensive list of supplier companies.

Cutting tools are used on machine tools to cut metal, and are one component of the overall mold machining process to consider when looking to improve speeds, feeds, wear and surface finish. This week, we look at some highlighted cutting tools, which range from products that can help with finishing high-temperature superalloys in either continuous or interrupted cuts, handle both roughing and finishing operations effectively in all material types, enable access to clean fixturing surfaces and quick setup changes or make fine adjustments possible.

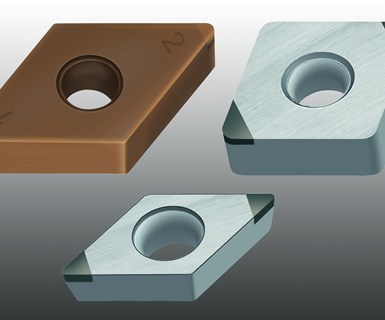

Walter introduces CBN grades WBH10C, WBH10 and WBH20 for improved turning of hardened steel up to 65 HRC. These grades provide users high quality surface finish with wiper geometry and long tool life with TiAlSiN-coated CBN grade (WBH10C). Inserts with laser etched chip breaker geometry TM-M2 are also available. All inserts are ground for process reliability. The grades are available in both positive and negative inserts and are suitable for both continuous and interrupted cuts.

Additionally, the company has also introduced WBS10, a CBN grade for finishing high-temperature superalloys in either continuous or interrupted cuts. Available in both positive and negative inserts, WBS10 features sharp “EM2” microgeometry and superfine grain with ceramic binder.

Seco expands its Niagara Cutter Stabilizer product family with the addition of the ST540 five-flute end mill. The STS540, STSN540, STR540, STRN540 and STRCS540 family of solid carbide end mills offers complete solutions for machining processes ranging from slot milling to side mill finishing as well as those involving up to 40% radial stepovers for fast material removal thanks to strong cutting edges and full eccentric reliefs.

In addition to smaller diameter tools for high-performance milling and 140 new inch sizes, including a new necked version for long-reach applications, the expansion also includes advanced helical chip splitters developed by Niagara Cutter to ensure good chip evacuation in even the most challenging applications. An offset design ensures superior surface finishes and makes for an all-in-one end mill solution that can handle both roughing and finishing operations and is equally effective in all material types, from steel to cast iron and stainless steels to superalloys.

Big Kaiser announces ChipFans and T-slot covers, two accessories crafted to improve in-process efficiency by helping machines reach maximum levels of productivity, even during downtime.

ChipFans offer many benefits when it comes to mitigating production issues and providing visible results. Mounting securely in either a collet chuck or end mill holder, chip fans are designed to integrate seamlessly into current machining cycles. In-process cleaning is created without halting production. Chip fan cycles can be programmed to minimize spindle downtime and maximize operator efficiency. A pre-drilled hole enables spindles to shoot coolant through the center of the fan to rinse tables, fixtures and workpieces. Two cleaning operations in one happen as the fan rotates, removing the chips and coolant, making a safe and economical alternative that requires little to no operator interaction.

The T-slot cover tool accessory serves to optimize machine performance, minimize manual operations and keep things running smoothly. The protection plates are designed with productivity in mind, preventing chips and coolant from collecting in machining centers and interfering with work. The covers keep slots clear of debris when not in use. The T-slot covers are easy to remove as soon as the machine slots are ready to be used, enabling access to a clean fixturing surface and quick setup changes.

Tungaloy expands its DeepTriDrill line of indexable gun drills to include new drill diameters ranging from ø12.0 mm to ø13.5 mm.

DeepTriDrill can address diverse deep drilling needs of automotive and mold set parts for maximum efficiency and stability. In addition, the drill diameter can easily be altered in increments of 0.01 mm to the required hole sizes simply by placing dedicated adjusting shims beneath the guide pads, enabling an overall reduction of cycle time and manufacturing costs in diverse deep drilling applications. A high precision H-class insert with cutting edge configuration provides hole accuracy at greater feed rates, while ensuring smooth chip evacuation. The drill reduces tool setup time with easy insert indexing, and fine adjustments are possible with dedicated adjusting shims.

Interested in More on Cutting Tools?

Be sure to check out the Cutting Tools Zone for the latest articles, blogs, products, news and videos.

Browse our entire database of moldmaking products in the products section. You can browse to stay updated on the latest product offerings, or search for specific product information based on categories.

.png;maxWidth=300;quality=90)