Systems Engineering Meets Moldmaking

A combination of systems engineering and systems integration approaches improves communication, which yields better mold manufacturing overall.

Share

Is systems engineering necessary for moldmakers? The answer depends on what you include and exclude from systems engineering, and on whom you ask.

A typical reply from moldmakers is, “We have been building molds here for 20 years. For even the largest and most complicated jobs, our customers know we will perform. Systems engineering is for inventing new things.” But as with so many other technical topics, the truth lies deeper.

To address this deeper truth, consider the large market for injection-molded automotive interior trim panels. These plastic trim panels that form the interiors of cars and light trucks are both decorative and functional. Interior trim surfaces can be important selling points in dealership showrooms, where appearances are anything but superficial. Much attention and expense are devoted to dashboards, instrument panels, headliners above the windshields, inner door panels and consoles between the front seats.

Trim panels are regularly redesigned to incorporate the newest ideas in luxury, such as leather-like textures or visually complex and appealing burlwood. Given the increased incorporation of electronics in vehicles, there are often new digital features to accommodate, while layouts of gauges, readouts and climate controls regularly need to be redesigned or refreshed.

In other words, complexity, continuous innovation and speed rule the interior trim moldmaking business. To cope, many moldmakers rely on systems engineering in some way.

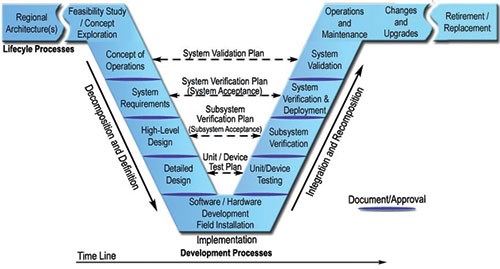

Although moldmakers generally agree that systems engineering in its formal sense (see Figure 1) is best left to the OEMs, they still need a portion of the systems engineering Vee diagram. And those moldmakers who expect systems engineering to play a large future role in their business are steadily enlarging their understanding of its processes.

In the practical world of getting injection-molded parts out the door, moldmakers who use systems engineering note that it is linked to systems integration.

This Vee diagram is the most common schematic of systems engineering, but it lacks all-important communication factors. Wilbert Plastics’ Wayne Hertlein says it does not reflect essential and constant communication among Tier 1s, 2s and 3s and with the OEM, and there are no feedback loops.

Sorting Out the Terminology

Combining the principles of systems engineering and systems integration can improve communication, resulting in better overall mold manufacturing. A review of some fundamental terminology is a good place to start in explaining this double-duty approach to managing shopfloor operations.

Systems engineering is an interdisciplinary that focuses on defining customer needs and required functionality early in the development cycle, documenting requirements, then proceeding with design synthesis and system validation, all while considering the complete problem: operations cost and scheduling, performance and evaluation, manufacturing, testing, training, support, and disposal. It integrates a variety of disciplines and specialty groups into a team effort, forming a structured development process that proceeds from concept to production to operation. It considers both the business and the technical needs of all customers with the goal of providing a quality product that meets the user’s needs.

Systems integration connects the factory floor systems of production—machining, testing and evaluation, and assembly—and their electrical/electronic controls, plus ergonomics and safety, material handling and packaging. Systems integration focuses on the actual assets rather than intellectual assets. It is the “physical” counterpart to systems engineering.

Both systems engineering and systems integration are strategic. They are proven approaches to the management of product engineering and development.

Complexity Calls for Communication

For moldmaking, systems engineering and systems integration are two sides of the same fundamental coin, which are necessary to carefully manage the myriad of processes on which the enterprise is built. And within moldmaking, that enterprise is complex.

If moldmakers expect one trend to continue, that would be complexity—both in the ceaseless need for innovation in the products for which they make tooling and in the tooling itself. That makes this a good time to look into the use of systems engineering and systems integration in moldmaking.

“Complexity is everywhere in moldmaking,” says Wayne Hertlein, program manager at Wilbert Plastic Services in Troy, Michigan. “As a result, we have many masters.” Thorough communications and deep understanding of programs take precedence over any formalized systems engineering approach.

“Communication has to sort out the many possible conflicts in a mold program.” Among the many potential conflicts he sees:

• Feasibility, manufacturability or “tolerability” studies to determine whether a part can be molded as designed.

• Mold design and manufacture, and computerized mold flow analysis and optimization.

• Alignments throughout the program such as stage gates (go/no-go decisions), part runoff and approval levels, terms and conditions, and quoting.

• A squeeze between the due dates for the parts and delivery of the tool steel blocks from which the mold components will be machined.

• The imperative to fully understand the people and planning processes of the OEM automaker, the large Tier 1 supplier providing a vehicle’s “cabin,” the Tier 3 “build-to-print” suppliers of parts and components, and the injection molder/moldmaker itself.

Wilbert Plastics usually works as a Tier 2 supplier of custom-built mold tooling. It sells to medical, telecommunications and toy markets, as well as automotive. “We strive for no surprises,”

Hertlein says. “Surprises are almost always painful.”

MGS Manufacturing Group uses both systems engineering and systems integration, says John Berg, director of marketing. One of the automotive industry’s largest mold producers, the Germantown, Wisconsin-company builds about 300 molds a year, achieving $40 million in tooling sales.

Systems engineering and systems integration blend neatly into MGS Manufacturing’s hands-on, face-to-face approach to project management. “We embrace the methodology of systems engineering,” Berg says. “It would be impossible to consistently deliver the high-end, complex and multi-functional tooling systems we build without it.”

There are dozens of phases in an injection mold project, and all of them must be tracked and managed. “There are too many tight tolerances, too many tight deadlines and too many different tasks to expect success if each phase were managed separately,” Berg notes. “We must have constant communication, reporting and evaluation.” That can only be provided by a cohesive approach to systems engineering and systems integration.

The systems engineering part of MGS Manufacturing’s operations is based on the need to pull together the basics of every mold and tool build. For every moldmaker, these include design-for-manufacture of the molded part, design of the mold cavity, material selection and procurement, machining operations and their programming, validating and fitting the steel components of the mold core, mold assembly and testing, and functional sampling of parts.

Many MGS Manufacturing projects are very ambitious. “The geometry of the molded parts can be challenging, with tight dimensional tolerances, strict flatness specifications and thin walls,” Berg says. “To create some part features, complex mold actions are required. We may have to work with multiple materials, multiple sets of mold cores and multiple sets of cavities. Cycle times and lead times are often very aggressive. All of these require additional resources, more elaborate planning and closer project management. Taking a systems engineering approach is invaluable.”

MGS Manufacturing puts systems integration to the test in its turnkey manufacturing operations. “Systems integration is the solution when a customer needs everything,” Berg explains. “We will supply design-for-manufacture engineering services, physical tooling such as an injection mold, specialty molding equipment, robotic systems, end-of-arm tooling, and inspection fixtures for assembly/nesting/decorating.”

Turnkey molding operations may also require extensive automation, packaging of the molded parts to OEM specifications, and training the team of users in operations, troubleshooting and maintenance, he says. The company also has in-house injection molding operations.

Unlike smaller mold builders, MGS Manufacturing has its own staff of programmers and code writers. They write standalone proprietary code as well as plug-ins and add-ons to commercial applications. The company also has invested heavily in machining centers, coordinate measuring machines, virtual machining applications (process simulation /digital manufacturing), mold flow simulation, CAD/CAM and robotics.

According to Berg, like every other business, MGS Manufacturing has computerized the methods it uses to manage projects, but it still uses actual, physical means as the primary tool set for communications. This means:

• Speaking face to face with anyone directly affected by any decision.

• Scheduling using computerized systems but backed up the tried-and-true way. Large printouts of machine schedules and work loads hang in the shop lunchroom, where they can be seen by everyone and regularly updated. “With one sweeping look, teams learn what is scheduled in every production unit,” Berg says. “The printouts show which teams may need additional resources and which teams have resources to share.”

Berg notes that every decision and action is documented and electronically accessible. “We cannot risk errors due to miscommunication or erroneous assumptions.” Otherwise systems engineering will not be effective, nor will systems integration.

Rockwell Automation’s Plastic Technology unit uses model-based systems engineering, an approach usually employed in aerospace engineering. “For the most part, we follow the traditional systems management lifecycle,” says Victor Baez, unit manager in Milwaukee. “We use some systems developed in-house, but we have support from enterprise-level business applications and database technologies suppliers, as well as product lifecycle, CAD and solid modeling, and supply chain management solutions.

“We have developed an internal stage-gate process to manage the lifecycle of production. Our product engineers own the processes and drive them from development engineering through all quality and engineering functions, and then through release to production.”

The use of owned processes is a proven way to ensure consistency within both systems engineering and systems integration. Bottlenecks are avoided, customer requirements and deadlines are met, waste is minimized, quality is assured, and budgets are not blown.

“The biggest gains are in data management from development to the customer and back to us; data management is also the biggest source of pain,” Baez explains. “The future at Rockwell Plastics is to extend systems engineering from the product/tooling level to the component level. This means integration with suppliers as well as internal improvements.”

Summary

This story does not end in a mold shop checking out an automated molding and parts-handling system. It does not end in a Tier 1 supplier factory that makes parts for car or small-truck interiors. Nor on an automaker’s final assembly line.

Instead, this systems engineering/systems integration story ends in a dealership showroom. Automobile salespeople know very well the importance of what meets a prospect’s eye when he or she first gets into a vehicle—the instrument panel, the front-seat console, the headliner and the inner door panels. When these features look good and fit together snugly, they elicit smiles and help get signed sales agreements.

Related Content

How to Determine the Proper Vent Depth

Vent depth is critical to optimizing mold performance, so here is one approach to finding that elusive right number.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreLine Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

Read More