Successful mold builders are constantly honing their competitive advantage while managing the challenges of receiving accurate, timely customer data for making quality parts with ever-shortening lead times. Leading shops recognize that better integration of technology, processes, worker skill-sets, workpiece processing capabilities, shop floor, program and schedule management and the effective integration of the Internet of Things and Industry 4.0 can make a significant contribution to meeting and overcoming these challenges. Upgrading your existing ISO 9001:2008 system to ISO 9001:2015 is one way that your shop can achieve this improved integration to increase employee engagement, accelerate performance improvement and increase profits.

MoldMaking Technology kicked off an ISO 9000 series with its premier issue back in 1998, and this certification is still of great importance today. Moldmaking requires a high degree of integration among multiple functional areas. A closer look at the standard itself and how it has evolved is important to understand how an enlightened approach to upgrading to ISO 9001:2015 will improve the effectiveness of integration and process performance for your shop.

MoldMaking Technology kicked off an ISO 9000 series with its premier issue back in 1998, and this certification is still of great importance today.

Challenges of a Changing Standard

As part of its ongoing improvement process, the International Standards Organization (ISO) has issued ISO 9001:2015 to replace ISO 9001:2008. Companies intending to maintain their ISO 9001 certification must transition to the new ISO 9001:2015 standard by September 15, 2018. According to the International Accreditation Forum (IAF), all certification bodies have been required to conduct all ISO 9001 and ISO 14001 initial surveillance and recertification audits to the new versions (ISO 9001:2015 and ISO 14001:2015) starting March 15, 2018.

The upgrade involves new requirements and sections, moving specific elements to different sections and splitting and re-locating elements to other sections. However, four significant changes include integrating actions to address risk, engaging interested parties, increasing emphasis on a process-based approach and a new, 10-section structure instead of an eight-section structure.

The initial 1988 structure of ISO 9000 had 18 or 20 sections, depending on whether a company’s operations included a Design section. The 1994 version eliminated ISO 9002 and standardized ISO 9001 with 20 sections. The 2000 version of the standard changed the structure to eight sections with sub-sections. The 2008 version of ISO 9001 retained this structure. The 2015 version of ISO 9001 now has 10 sections, and it includes the shifts of existing sub-sections to new areas of the standard.

If your system was based on procedures written to match the structure of the standard, then any one of these changes caused a major disruption in your system documentation. You needed (or still need, if you are retaining a procedure-based system) to find the new location of each element in the new system and re-number your sections or create another way for everyone in the organization to be on the same page.

Even if you manage to keep track of all these changes, you still end up with thick notebooks of procedures. These text-based documents may describe your business in terms of the standard (literally, “document what you do and do what you document”). However, these documents represent a bureaucratic layer of documentation that is on top of your business, not a part of it. These documents do little to help you address and overcome the challenges that are described in the opening paragraphs of this article.

A procedure-based documentation system also complicates your ability to achieve a significant objective to address risk, which is introduced in ISO 9001:2015. A procedure-based system breaks the natural connections in a company’s operations down and re-distributes them according to the sections of the standard. Without a clear picture of the connections among all the processes of the business, it is difficult to get a meaningful grasp of risk, especially in the complex operating environment of a mold builder. A separate risk analysis process on top of procedure-based documentation further complicates the system without effectively identifying and eliminating or mitigating risk.

Using Process to Solve the Problem

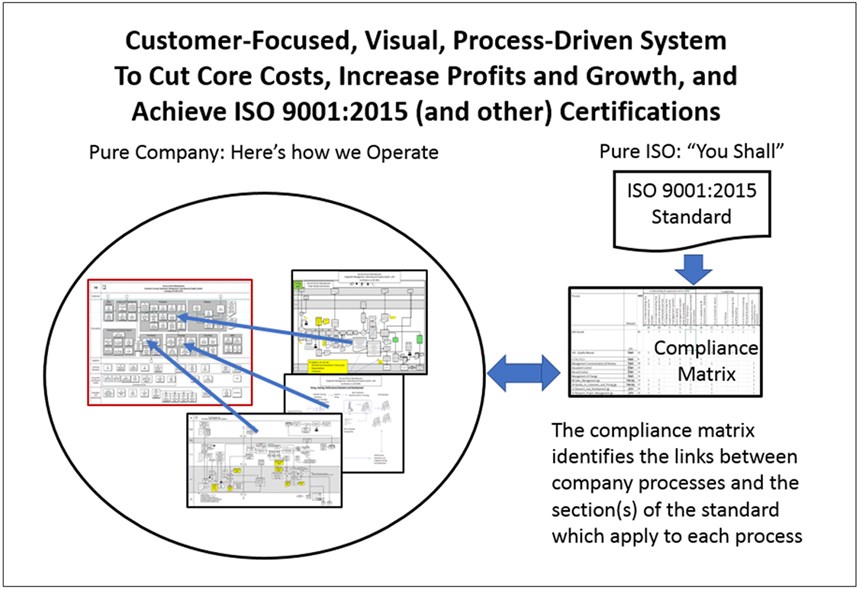

While procedure-based systems start with the standard and work backward, process-based systems start with the actual activities and processes of your business and support your management and employees in moving your shop forward.

While procedure-based systems start with the standard and work backward, process-based systems start with the actual processes of your business and support your management and employees in moving your shop forward.

For the first time, the ISO 9001:2015 standard explicitly recognizes principles involved in the use of visual, process-based systems and a compliance matrix to achieve improved performance and certification. The standard states, “It is not the intent of this International Standard to imply the need for alignment of documentation to the clause structure of this International Standard and use of the specific terminology of this International Standard within the organization.” In other words, you do not have to incorporate the specific words in any element of the standard in your documentation.

The foundation for developing visual, process-based systems is identifying the actual activities that take place in your shop, within and across functions and levels. These activities are then gathered into the “natural processes” of your business, which are defined as ones that have logical start points (a clear input or set of inputs), processing and activities that occur from that point, and a clear output or outputs.

The activities that actually take place often differ from what the existing documentation of the system describes. For example, documentation may be out of date because of the typically cumbersome actions that are required to update a procedure-based system. Text-based procedures make it easy to leave “loose ends” in describing how operations work, and the documentation may not address real issues in an integrated business like mold building. Alternatively, where parts of the system are not documented, differing perceptions of how a process actually works may exist. For example, there may be differing perceptions among the employees at your shop over the work your shop performs, the problems that exist and the opportunities that are available.

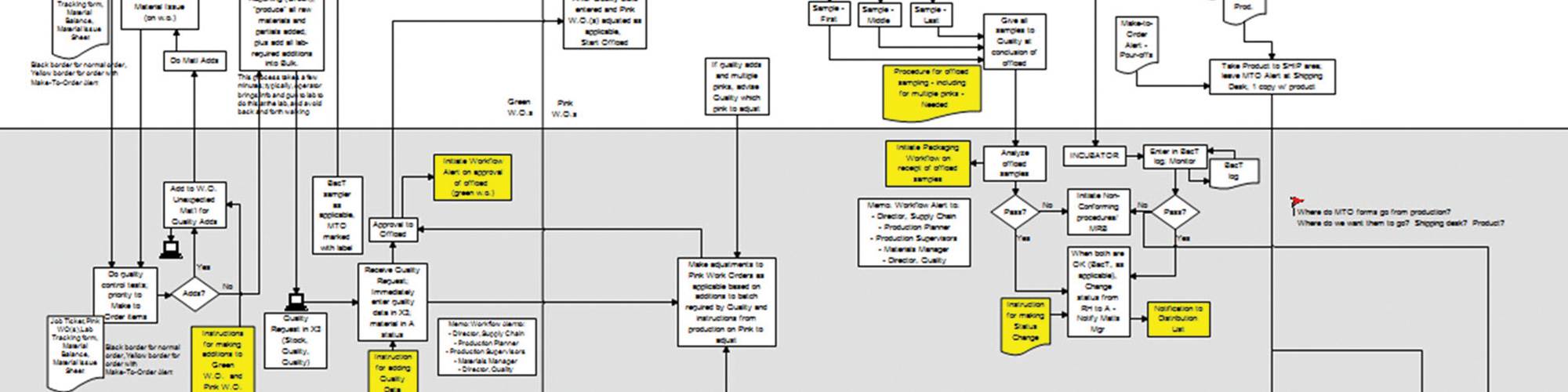

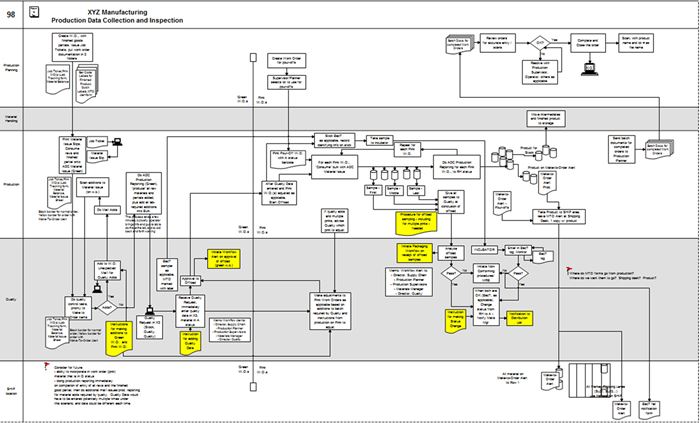

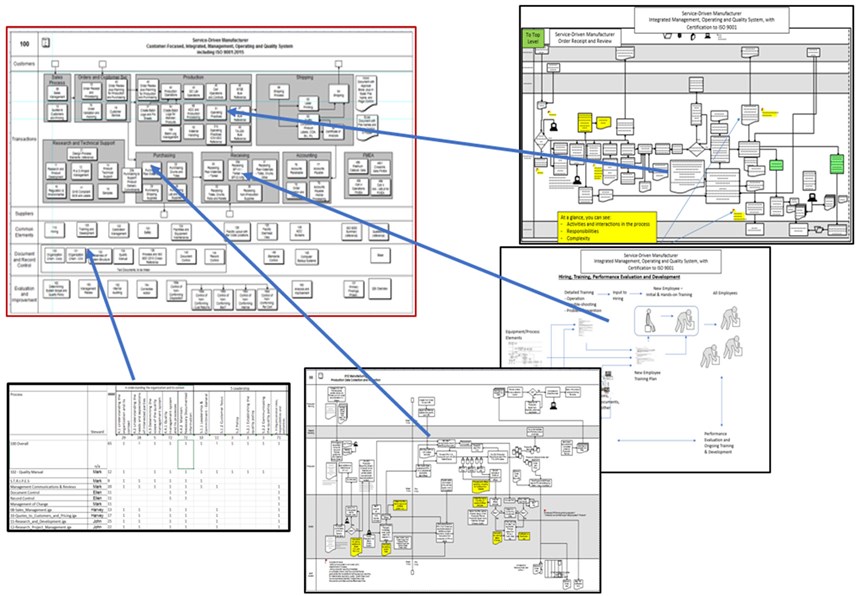

Figure 1 is an example of a deployment process map, which clearly establishes the functions involved in a process, the activities in each function (with responsibilities and authorities) and inter-relationships among activities in different functions, all in one place. This natural process shows what functions are involved, the inputs, the sequence and the interaction among the activities in the various functions, transfers of information or material to different functions and the outputs of the process. This visual view also provides a visceral indication of the complexity and potential risks involved in the process. Figure 2 shows all of the individual natural process maps linked to a top-level map, creating a company-wide, integrated management, operating and quality system, which is completely focused on the company’s processes and operations.

Identifying Activities and Information

The best sources for the information on the actual activities within a business are the existing documentation, people overseeing the work and people doing the work. The accuracy of existing documents can be suspect for several reasons, including the difficulty with updating procedure-based systems that can cause existing procedures to be out-of-date or no longer applicable as written. Also, text-based procedures lack the essential “a picture is worth a thousand words” characteristic of a deployment-process map, and they have loose ends that are not apparent.

Managers, supervisors or others not doing the specific work in a process every day may have expertise in the area, but they often lack the detailed, hands-on knowledge that is essential in capturing the actual actions and interactions from which issues and solutions can be developed. The people who actually do the work can share what actually happens. For example, they can describe the variety of situations and interactions among people inside and outside of their functional areas and any developed workarounds. The people who do this every day are the world’s experts at knowing what they actually do (which is their local system) and are the best source of the information about how current activities and processes actually work.

Effectively capturing existing activities and processes should be conducted on a no-fault basis, which means that any issues identified should not be fodder for blame but should be pursued as opportunities to further develop and grow the business. Pursuing the required actions quickly with the management and employees involved as part of the solution will develop buy-in, participation and contribute to change.

Another essential feature of the capture and documentation process is an objective approach to identify what actually happens without incorporating assumptions or bias to solutions. Outside resources can provide this objectivity while avoiding internal conflicts, and outside sources can shorten the time required for a full capture of thesystem.

Complying With Standards and Achieving Certification

Any given process area of your shop can address multiple elements in ISO 9001:2015, and one element of ISO 9001:2015 can be addressed in multiple areas of your shop. A compliance matrix (see Figure 3) will make identifying connections and demonstrating compliance easier. This matrix consists of a list of the company’s processes on the left-hand side and a list of the standard’s elements across the top. For a given process, the body of the matrix identifies which elements of the standard are addressed. For a given element of the standard, the body of the matrix simultaneously indicates which processes in the company have content that addresses that element of the standard.

This approach enables you to keep your processes in the language of your shop while easily demonstrating compliance to ISO 9001:2015. In fact, you can use the same approach to demonstrate how your processes comply with other standards (ISO 14001, IATF 16949, AS 9100 and so on) without creating separate systems.

This approach enables you to keep your processes in the language of your shop while easily demonstrating compliance to ISO 9001:2015.

It is widely recognized that many of the issues facing companies today are embedded in the system, which includes people, processes, information, technology, machinery, equipment and culture. To identify and address these issues, engage your employees, capture the actual activities and interactions in your shop, document the language of your business visually, focus on developing a common understanding of activities, risks and opportunities and take action immediately to develop buy-in, participation and contribution to change. Using the visual, process-based approach to upgrade your certification to ISO 9001:2015 will yield outcomes that improve lead times and increase business growth and profitability.

About the Contributor

Paul Vragel

Paul Vragel is the president of 4aBetterBusiness.

Related Content

Dynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

Read MoreThe Critical Role of Management Representatives in ISO 9001

In ISO 9001 quality management systems, the Management Representative (MR) plays a crucial role. While the 2015 version of ISO 9001 no longer mandates this position, having a trusted management member serve as an MR remains vital for streamlining operations and maintaining quality standards.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreTop 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

Read MoreRead Next

Keeping Up with ISO: A New High-Level Structure

Examining and complying with the first three revised clauses in ISO 9001:2015 should enable your company to produce metrics on problem areas, track customer feedback and establish a change-management process.

Read MoreKeeping Up with ISO: A New High-Level Structure, Part 2

Here's a look at Clauses 4.0-6.0 in ISO 9001:2015.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More