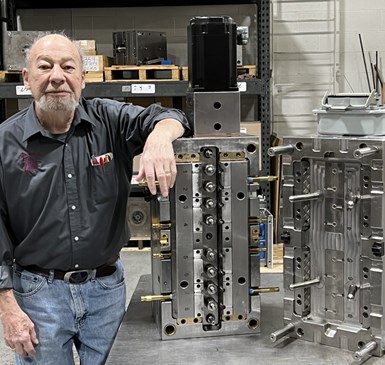

B A Die Mold Founder and Owner Al Petrucci takes pride in the team’s innovation, personalized service and collective experience in mold manufacturing. Source, all images: B A Die Mold Inc.

Celebrating 56 years in business is quite a milestone, especially in the moldmaking industry. That’s why MMT made a point of sitting down with Alan Petrucci, founder and CEO, and Francine Petrucci, president, of B A Die Mold Inc.

Humbled and proud, Al reflects on years gone by and how the company has evolved to remain competitive, while Francine shares her plans and predictions for the future of the business.

How does it feel to reach 56 years in business?

Al Petrucci, founder and CEO, B A Die Mold: I feel very fortunate that I have been able to keep this company going for 56 years. Business levels have been up and down over the years, but we have survived because of sales efforts, good management and good people. Innovations in unscrewing technology may have helped, too, but I believe our reputation for being expert problem solvers and manufacturers of high-quality molds, not to mention that we do a very good job servicing customers, has kept our customers coming back.

What is your favorite B A memory?

Al Petrucci: I have two wonderful memories. One is the blessing of having my family support me and work with me over the years, both at B A and at Imperial Plastics, a molding company we had for 13 years. Another memory is all of the great people that I’ve met. Looking back, I see that many of my customers who worked as engineers for various customers have become good friends.

I should mention that being named Mold Maker of the Year by the American Mold Builders Association (AMBA) in 2011 remains a special memory. I was taken by surprise and very humbled to receive the award from my peers — so much so that all I could say was “thank you” and “I love what I do.”

What is your most meaningful B A milestone?

Al Petrucci: I think it would be building our plant. There is something very meaningful and fulfilling about owning your facility and everything inside it.

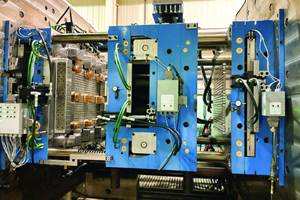

Additionally, achieving our patent for the PERC (programmable electric rotating core) System for unscrewing molds is extremely meaningful. It further solidified B A Die Mold’s reputation as a company that excels in designing and building unscrewing molds, especially challenging ones.

I would also include a patent that I share with a major medical device manufacturing customer, who I can’t name, but the device required an extremely complex injection mold, which I designed and manufactured. It makes a part that surgeons use to guide a wire through arteries to place stents during angioplasty.

What has been the biggest change over the last 56 years at B A?

B A Die Mold specializes in unscrewing and multi-action tooling for highly engineered parts and also designs and manufactures high-quality molds.

Al Petrucci: Number one is foreign competition, the government enacting NAFTA and preferred nation trading status with China, which, as everyone knows, caused many issues for American shops. So, many of our customers closed or sold — we lost a lot of longtime customers that way. A significant number of mold builders have gone out of business as well!

At B A, it caused us to go from more than 30 employees to less than 20 for a while. It reduced our customer base or caused us to lose a significant amount of work from existing customers as well, so we regrouped and tried to be more aggressive with sales and the pursuit of new customers who would appreciate quality molds and accessibility of vendors. Basically, we hired outside sales personnel, upgraded our machines and focused on threaded parts, which is our expertise.

You mention how foreign competition has affected your company and the industry in your answer to the previous question. Can you share any other notable changes in the moldmaking industry that have occurred since you founded your company 55 years ago?

Al Petrucci: CNC machining came after my time on the bench, so I never got into that. When I first learned the craft of moldmaking, we did not even have EDM. Sinker EDMs came along later. It was primarily Bridgeport machines, boring mills and duplicating machines that were used. I think the advent of EDM and CNC machining, along with the computer programming capabilities and hot runner systems that came to be, enabled a lot more products to be made in plastic.

We could perform complex work before these newer technologies were introduced, but it was time-intensive and expensive, and we were limited by how intricate parts could be. The arrival of lasers for engraving and forming fine details, along with 3D printing, also altered how molds are built. A lot has changed to make mold manufacturing far more efficient and precise.

What has been your most interesting customer project or experience?

Al Petrucci: There are countless interesting projects that we have worked on. Really, they are all interesting in some way or another and challenging. If I had to choose one project, it would probably be the design and build of a mold for a water filtration filter head. We came up with a way to make an unscrewing mold that unscrewed both horizontally and vertically and allowed them to put an on-off valve in the filter head.

That project was the inspiration for developing our PERC System. That was probably the most interesting and satisfying project for us because it was quite challenging, and we developed a very effective and precise system to mold complex, threaded parts. We built a few more molds like that for this customer, and they are still in production today, more than 30 years later.

What was B A's most difficult customer project?

Al Petrucci: We designed and built a mold that could mold starch capsules for medications that had to be tamper-evident. That project came about after the Tylenol scare when someone put a poisonous substance into the product. The customer hoped to be able to produce a safer capsule for medications as well as vitamins.

I worked with the customer to develop a hot runner system that would mold starch. That system was built by Melt Design Inc. here in the Chicago area. We succeeded, and once molded, the capsules would be filled and then closed and welded together with water using an automated process. Once dried, the starch capsules would shatter if anyone attempted to reopen or inject them.

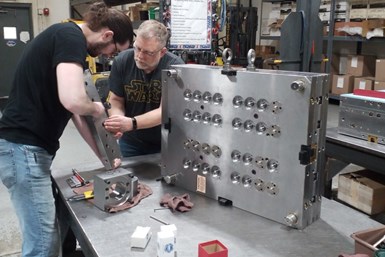

B A Die Mold provides short-run molding, in-house tryouts and low-volume production runs. Here an apprentice performs a secondary operation on a filter head.

At 83, you are still working. How often are you at B A and what are you primarily focused on?

Al Petrucci: I work three days a week, usually for four or five hours a day. My focus is design engineering and estimating. Francine is running the shop.

How does it feel to have your daughter, Francine, working with you and leading the company today?

Al Petrucci: It has been great, but I am not used to having a boss (smiles). She’s been with us for nearly 30 years, since graduating from college, and even before that, working part-time during school breaks from high school and college. I'm confident in her because she is very capable and she loves this industry like I do.

Francine, as Al's successor with some strategic plans in place, let’s delve into

Francine Petrucci, B A Die Mold President and Co-Owner, works with her father Al to collaborate with the team, infusing passion and dedication into every project.

your qualifications, leadership style, vision for the business and approach to potential challenges. Can you share your experience and background in the mold industry?

Francine Petrucci, president, B A Mold Inc.: I have always planned to be involved in the business from a young age because I love this industry. I worked for my dad in the office during school breaks and then after high school, I earned a Bachelor’s degree in engineering, graduating Cum Laude. I have worked full-time in the industry ever since, starting in our shop’s CNC and quality assurance departments before moving on to administrative duties and office management.

Today, I am the company cheerleader. I strive to impress upon my team my passion for building a quality product. We spend a lot of time together every week, so we want B A to be a workplace the team looks forward to coming to every day. Similarly, I communicate that same passion to our customers so they understand B A’s dedication to bringing success to every project — large or small.

How do you plan to leverage new technologies and industry trends to ensure B A’s competitiveness in the coming years?

Francine Petrucci: We have been exploring 3D printing and are considering bringing that technology into the shop. We are also actively seeking to add employees skilled in using the latest machining techniques and software. We can teach them the finer points of injection mold manufacturing. We are currently developing the talents of four new team members who have strong machining skills from other industries like automation.

B A Die Mold engages in direct consultations with customers throughout the mold design and build process, ensuring manufacturability. They refer to this collaborative approach as “co-development.”

What leadership qualities do you believe are essential for successfully guiding the business through a period of transition and growth?

Francine Petrucci: Being knowledgeable in mold manufacturing and plastics, of course, but I believe good people skills and the ability to communicate effectively with employees and customers are paramount to achieving any goal.

In what ways do you envision building upon the legacy of the mold shop while introducing your contributions to its success?

Francine Petrucci: Building solid relationships with customers and vendors through the application of personalized attention and honorable, highly skilled work. My dad built this company by doing just that and has many longtime friendships that have resulted. I will also continue to assist customers with creating the best possible designs to improve moldability.

Al, last but not least, what are your plans for B A and retirement?

Al Petrucci: I am hoping to retire when I am 85. As far as plans for B A are concerned, that is in Francine’s wheelhouse. She’s already looking at some strategic plans. My dream was to add on to our building and put in a dozen molding machines and perhaps a cleanroom because we build many molds for medical applications. We built our facility for expansion, so we have the power and the water. We will see what the future brings. B A is strong. We have a lot of good people here who are very good at what they do. Anything could happen.

Since 1968, B A Die Mold's has accumulated extensive moldmaking experience in close-tolerance fittings, consumer goods, electrical, automotive and medical components, consistently delivering reliability, quality and productivity. This is a medical device with internal threads (six turns) manufactured using B A’s PERC System.

Related Content

Combining Innovation and Artistry to Build Complex, Precision, Multi-Cavity Molds

This Florida mold builder is about high-performance, high-precision moldmaking by blending craftsmanship with technology.

Read MoreCross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

Read MoreHigh-Technology, Diversified Mold Builder Has Its Eye on Improvement

Commitment, engineering expertise, flexibility, quality and customer service help Wisconsin moldmaker Triangle Tool LLC discover ways to grow and build molds faster.

Read MoreNext-Generation Thinkers Redefine Moldmaking Quality and Service

Canada-based NextGen Mold Technologies is a new mold shop using excitement and empowerment to encourage better ideas every day.

Read MoreRead Next

Alan Petrucci: An Industry Icon

Not content to rest on his laurels, this moldmaking veteran continues to immerse himself in the business for nearly half a century.

Read MoreHonoring a Leading Woman in Manufacturing

Last week I blogged about Jim Hommer, Sr., who was honored with the Technology and Manufacturing Association’s Winzeler Award at its Annual Meeting earlier this month. Today I’m going to tell you about the second of three honorees from that event: Francine Petrucci.

Read MoreB A Die Mold PERC System Proves Performance and Accuracy for Unscrewing Applications

Amerimold 2021 exhibitor B A Die Mold develops a compact, high-speed, high-torque and high-precision system that is fully programmable, accurate and requires little to no maintenance.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)