Software Packages Streamline Design Seamlessly

New software seats provide quicker design and toolpath generation—resulting in increased throughput without spending a lot of money.

|

Using software from VX Corp. (Palm Bay, FL), two moldmakers with distinctly different specialties but facing similar challenges have been able to shorten leadtimes relatively inexpensively without sacrificing quality. Kimball, MI-based Massobrio Precision Products Corp. (MPP)—a producer of standard open and shut injection molds, two-shot rotational molds, stack molds and unscrewing molds—has 34 employees running two shifts to provide 24-hour coverage. Its mold sizes vary from small connectors and seat belt actuators up to fan shrouds requiring a 1,000-ton press. High Point Archery (a division of High Point Tool, Wattsburgh, PA)—a plastic injection moldmaker for parts that range from consumer goods to its own product line of archery equipment—employs eight people. The company also makes the molds for the plastic tops for a major ladder manufacturer.

Facing ChallengesAccording to MPP’s Design Engineer Paul Konarzewski, the company’s biggest challenge is getting final part data in a timely manner from the customer. “With the faster turnaround required by customers it’s tough to meet customers delivery requirements when the customer delays supplying us with the final part data until the last minute,” he notes. “With these shortened turnaround times, we’ve found a need to bring on board additional programmers and bring them up to speed designing to our and our customers’ requirements. The cost to purchase additional full seats of good design software would make meeting customer’s delivery requirements extremely expensive.” Additionally, MPP typically holds part tolerances of +/- .002" (though tolerances of +/- .001" are not uncommon in special applications) and produces a full range of finish requirements. For Rick Leasure, president of High Point Archery, working with imported data that has gone through translators many times before, the company sees it is an ongoing challenge. Getting parts off of the machine with acceptable finishes and trying to eliminate part gouging also contributed to the company’s decision to look for a new software vendor. High Point Archery maintains tight tolerances of +/-.0005 on all of its work.

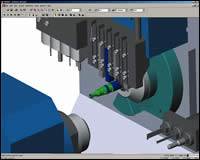

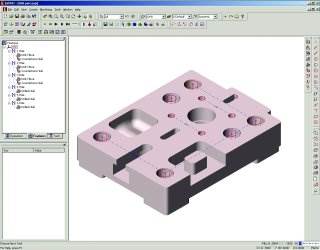

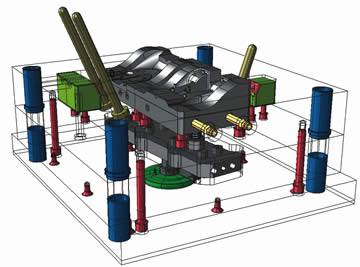

Perfect PackagesKonarzewski of MPP notes that VX “fit all of its requirements”—a low-cost, user-friendly system for both designing and machining—when he looked for a new software package. MPP purchased one seat of VX Modeler and one seat of VX End-to-End. “The cost of the package was what made us originally look at VX, but the ease of use and the great functionality is what made it the software of choice,” Konarzewski explains. “It is a low-cost, highly functional mold design option that has most of the ‘bells and whistles’ found in high-end software packages, but won’t empty out your checking account. We use VX for complete design, drafting and machining.” High Point Archery purchased two seats of VX End-to-End, also citing ease of use as the main reason for purchase—as well as its high-speed machining capabilities. The local rep for support also made the company’s decision easier, Leasure points out. “Basically, we bring in poor geometry and VX has Quickmill technology that gives us speed and accuracy without worrying about surface errors that will gouge the part,” he states. “The complete mold assembly can be created with the concept part, and we can see what we can modify on the product to allow it to be made easily. Since VX is fully associative, we can update the core/cavity and toolpath so we can easily see how long—and more importantly—have an accurate cost of the product before it goes into production. Plus it is fast at calculating—which saves time.” Leasure adds that the training time is “minimal.”

Satisfied CustomersBoth companies are extremely satisfied with their VX software purchase. According to High Point Archery’s Leasure, “We get parts on and off the machines faster, which gives us more throughput. Plus we can easily design our own product line and complete mold assemblies. VX is the easiest CAD program I have found on the market. The guys are less stressed about the programs running on the machines. We rough parts faster and we don’t seem to break cutters like before. Time is money.” Konarzewski of MPP adds that the software afforded the company a “low-cost solution to increase our design and machining functionality. It allows us to increase our design and toolpath generation output in a cost-conservative manner while still maintaining product quality.” Leasure of High Point Archery sums things up nicely. “Seamless design through manufacturing is what it is all about,” he affirms. “Designing our own parts gives us the freedom to come up with a design that can be made cost-effectively.” |

Related Content

How to Fix Predicted Warpage Before It Happens with Windage and CAD Model Morphing

Applying windage and model-morphing techniques saved toolmaker/molder Sturgis Molded Products the time, cost, headaches of multiple part/mold design iteration loops, cumbersome cooling fixtures, and long molding cycles.

Read MoreFour Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreHow a Small Programming Change Cuts Cycle Time in Half

Overriding the CAM system when milling a series of lifter pockets helps to improve metal removal rate and increase feed rates.

Read MoreRead Next

CAM Technology Trends

More than the products themselves, the CAM industry is changing the way it does business and moldmakers should take note.

Read MoreChoosing the Right Knowledge-Based CAD/CAM System

CAD/CAM systems that offer knowledge-based machining deliver tremendous savings in both time and costs, but only when the system meets your specific needs.

Read MoreA Specialized Mold Design Strategy

Solving complex mold design challenges with specialized CAD software.

Read More