SLIDESHOW: Technology Showcase – AMBA Plant Tours

On March 16th, two very different mold manufacturing companies opened their doors and hosted comprehensive tours of their facilities to members of the American Mold Builders Association (AMBA).

Share

Read Next

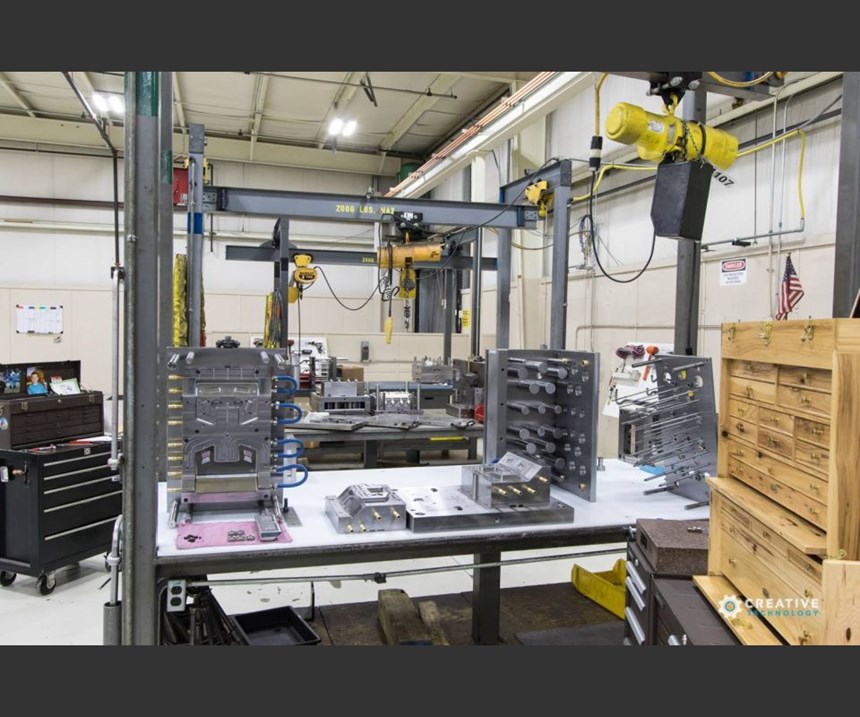

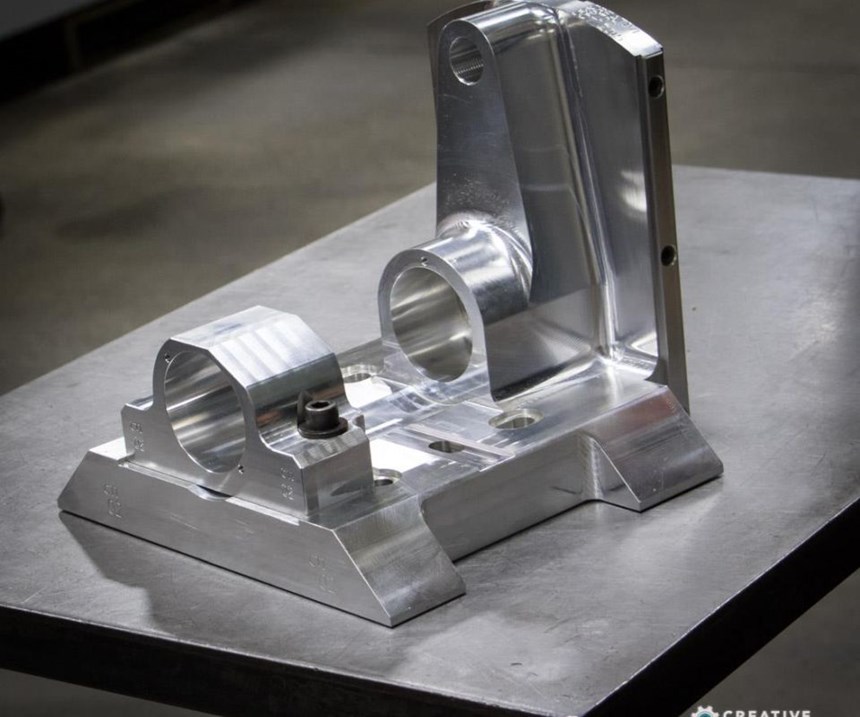

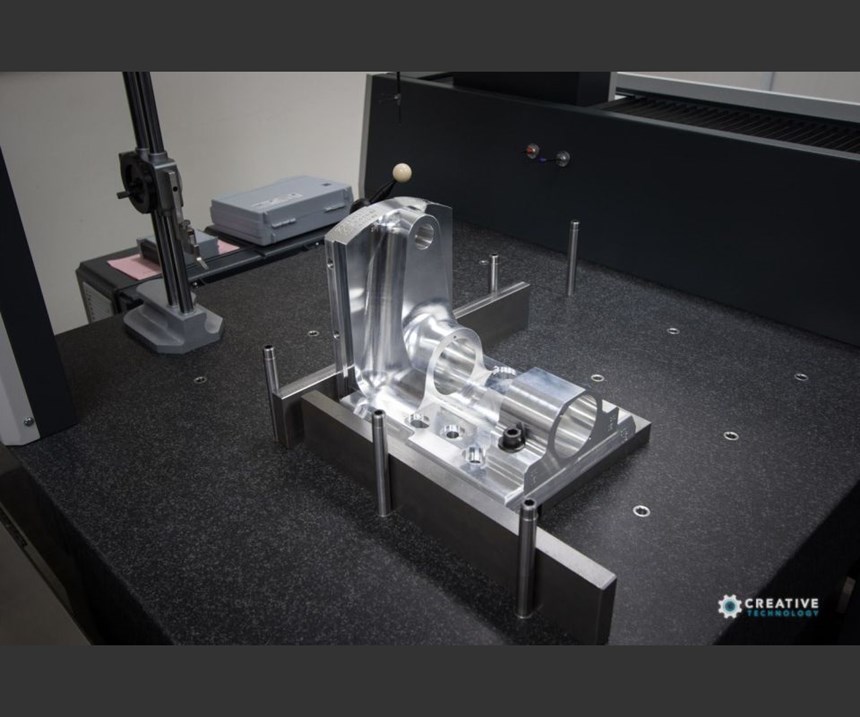

On March 16th, two very different mold manufacturing companies opened their doors and hosted comprehensive tours of their facilities to members of the American Mold Builders Association (AMBA). The shops were Vector Tool and Engineering, a subsidiary of Peterson Manufacturing that builds injection molds and tooling for the plastics industry, and Creative Blow Mold Tooling, which specializes in building plastic blow molds and plastic bottle mold tooling.

The AMBA has organized plant tours for its member companies for several years now, and they are very popular for obvious reasons, such as being able to see how another shop is set up, the equipment it runs, how it manages each job, how it manages its people, and so on. I’d like to share highlights from these tours with MMT readers today as my Technology Showcase. The images you will see in this slideshow are all courtesy of Todd Schuett from Creative Technology.

To learn more about each of these companies and see more images from the tours, visit their websites (links are embedded with each company’s name, above). You can also see images from previous industry events with the AMBA and other organizations by visiting Creative Technology’s Facebook page here.

Related Content

-

What is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

-

Think Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

-

The Critical Role of Management Representatives in ISO 9001

In ISO 9001 quality management systems, the Management Representative (MR) plays a crucial role. While the 2015 version of ISO 9001 no longer mandates this position, having a trusted management member serve as an MR remains vital for streamlining operations and maintaining quality standards.