Pursuing Perfection with Cold-Formed Cavities

A unique process for creating mirror-finish, tubular insert IDs has broken bottlenecks and driven this moldmaker to expand capabilities and raise quality standards.

Although doing something that no one else can is widely regarded as a path to success for any business, the truly unique are few and far between. Cavaform International LLC, a mold manufacturer in St. Petersburg, Florida, counts itself as a member of that rare company. “Cavaform” is a verb, too, says company President David Massie, explaining that the company takes its name from a process that creates mold cavities to ±0.0002-inch tolerances and 4-micron surface finishes with virtually perfect repeatability and very little polishing.

The Cavaforming process can be performed only on one piece of equipment: a 40-foot-long, 40-ton behemoth with capabilities that belie its primitive appearance and relatively easy operation. Indeed, a design dating from an era before CNC is actually an asset for the purposes of this machine, which employs a rotary hammering action to force an annealed steel tube around a hardened mandrel to impart the specified inner diameter (ID) geometry.

Known as rotary swaging, this cold-forming process isn’t unusual, Massie says. However, the machine itself certainly is, as is the way the process is being applied. In fact, to his knowledge, Cavaform is the only company in the world that swages plastic injection mold cavities.

Yet, Massie emphasizes that the Cavaforming process has shaped more than just metal during the past four decades. It’s shaped the identity of this business as well. In addition to driving growth from niche service provider to full-fledged mold manufacturer, the process has been the primary catalyst for the shop’s stringent quality standards, even for work that never sees the machine.

A Process Shapes a Shop

In fact, most of the shop’s work never sees the machine, which is used for only about 25 percent of all jobs. Despite the processes’ advantages, Massie says he’s confident that the 75-employee company would be highly competitive in designing, building, maintaining and repairing molds even if it were to somehow lose the rotary swaging machine. Other resources on the 32,000-square-foot shop floor include robot-fed, high-speed machining centers; CNC mills, turn-mills and lathes; OD, ID and centerless grinders; sinker, wire and hole-popping EDMs; and optical gaging systems and CMMs—all supported by modern design, machining and enterprise resource planning software. An adjacent 22,000-square-foot building contains nine injection presses for mold qualification, including turnkey setups. The shop has also moved into high- and low-volume molding production runs during the past few years.

Massie says he never intended to come this far. When the company got its start in the late ‘70s, the then-10,000-square-foot floor was outfitted only with equipment needed to support the Cavaform process (turning and OD grinding machines to make mandrels and prep barstock, as well as gundrills and hones to hollow out and polish the stock prior to swaging). By then, he and the founding staff were more than familiar with the process. It originated with a fateful conversation between his father and a friend who worked for die manufacturer Howell Penncraft. Upon hearing about his friend’s use of a rotary swaging machine to produce trimming dies, Bob Massie saw no reason why the process couldn’t impart hexagon, taper, square and other commonly swaged ID forms on much longer tubular components for molds produced at his own shop, Massie Tool & Mold.

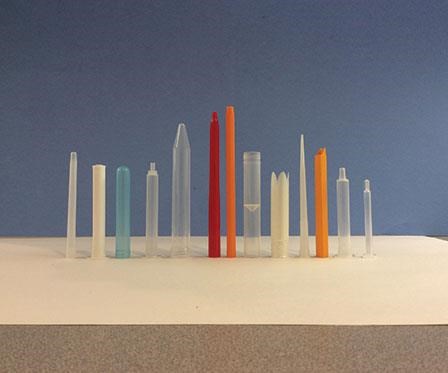

Before long, the die maker was supplying Massie Tool with rotary-swaged injection mold cavities for syringes, test tubes, pipettes, catheter tips, writing instruments, cosmetics and other such parts, and Bob Massie trademarked the term “Cavaform” (forming cavities) for this process in 1967. In 1972, his friend at Howell Penncraft notified him that another company was selling a similar machine, which was by then out of production. Massie Tool purchased it sight-unseen and moved it to Florida.

As the elder Massie neared retirement and began anticipating a buyout, he couldn’t bear the thought of the niche machine and unique application falling into the hands of another company. In 1978, a year before selling Massie Tool, he purchased a separate building to house the machine and put David and his other two sons at the helm of an entirely new business, one focused solely on Cavaformed IDs (that is, mold cavity blanks with no waterlines or other machined features). Within a few years, sales had more than doubled, and customers began asking for parts that are “fit for more than just show and tell,” David Massie says. Although increasingly lean OEMs and molders demanding additional services fit with a broader industry trend, this shop had an advantage when it came to expanding capabilities over the years: Simply having the Cavaform process as an option boosted mold-building capacity to levels that otherwise would have been impossible to handle.

The Bottleneck Breaker

“Can we Cavaform it?” is always the very first question when the shop wins a bid for a new job, and for good reason. The conventional process for a mold with, say, 32 hex-shaped pen cavities would be to machine multiple sinker EDM electrodes, burn the cavities, then carefully polish each and every one. Burning alone could take weeks, while polishing might take as long as half an hour per individual facet to achieve an SPI A-2 standard. In contrast, the Cavaform process takes only minutes to churn out fully finished ID shapes that typically require only light buffing after heat treating. Additionally, the riskiest and typically most difficult part of creating a full, ready-to-install cavity—forming the ID—is done first. Above all, the company’s EDM department and eight skilled polishers are free to focus on other work in the meantime. “It’s a bottleneck breaker,” Massie says.

There’s a reason why competitors have yet to replicate this capability, he says, noting that some even purchase their own mold cavities from Cavaform. Modern rotary swaging equipment not only tends to be customized for high-production applications that have nothing to do with moldmaking, but also tends to be far too light to cold-form mold steel. In contrast, Cavaform’s machine is a more generic design, the brainchild of German engineers employed by Cincinnati Milacron in the wake of WWII. Based heavily on models used to make rifle barrels during the war—often under fire in underground bunkers—the machine is “built like at tank,” Massie says.

What’s more, the machine’s fully mechanical operation makes it both reliable and relatively easy to use. So says George Hastick, who’s been running the machine for more than 20 years. At the heart of the process is the mandrel around which the annealed steel tube is formed. Essentially a core with the mirror image of the desired ID shape, this component is unique to each job and machined from high speed steel hardened to 60-63 HRC. Once polished within tolerance and, if need be, coated with titanium, a mandrel can last almost indefinitely, Hastick says. As many as 1,500 cavities have been manufactured from a single mandrel. This longevity provides the process with virtually perfect repeatability. That’s a huge asset not just for high volumes, but also for breaking customer bottlenecks through fast delivery of exacting replacements for worn or damaged cavity inserts. For this very purpose, the shop stores mandrels dating back decades near the machine in a large, dedicated cabinet.

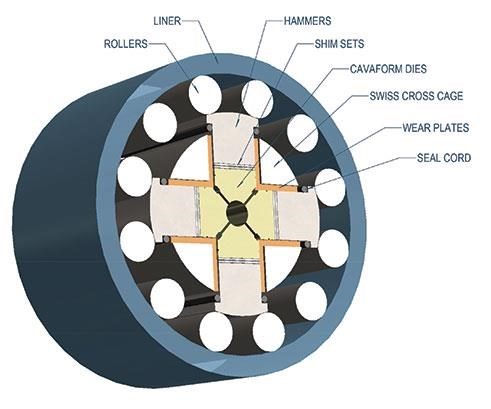

The mandrel and surrounding tubestock feed into the machine together between two opposing rods: a pusher rod with 60 tons of force and a back-pressure rod on a spring that prevents feeding too fast (feed rate is infinitely controllable, Hastick notes). Inside, the tube and mandrel are surrounded by four stress-relieved, cross-grained dies, all made in-house from M2 or M4 steel in a range of sizes. Behind each die is a hammer that extends back into the surrounding, circular enclosure, which is essentially a 3.5-foot-diameter roller bearing. Centrifugal force created by the rotation of the 220-rpm spindle drives the dies and hammers outward, and contact with the rolling elements inside the cage drives them back inward again. This creates a pulsating action that brings all four dies down on the advancing tubestock simultaneously and repeatedly with 75 tons of force each. (See the diagram on page 21).

With the die set opening and closing every 0.1 second, 300 total tons of radial pressure is sufficient force to crush any material softer than about 25 HRC down onto the mandrel. The resulting burnishing action accounts for the process’ capacity for precision and mirror surface finish, Hastick says. In fact, ID tolerances vary only a few ten-thousandths of an inch from cavity to cavity, even after subsequent heat-treating operations.

Making it Work

Despite the machine’s simple operation, experience matters, Massie says. For example, technicians like Hastick must determine the proper feed rate, materials and die-set size, as well as which of three oil formulations will provide the necessary cooling and lubrication to prevent galling. Precisely shaping mandrels within tolerance typically requires trial and error.

The shop also relies on its extensive experience to determine proper wall thickness. This is a critical concern for any job because, similarly to extrusion, the process doesn’t remove any material. Instead, steel essentially flows down the mandrel, increasing the length of the tube. Although the process works for most common mold steels (most applications involve 420SS, 440SS and H-13), any material is only so malleable. The more the tubestock ID must be compressed to form onto the mandrel, the more material is required to swage without adverse effects like work hardening. Essentially, narrower cavities require thicker walls (larger tubestock ODs), and wider cavities can be formed with thinner walls (smaller tubestock ODs). “What you do to the OD of the tubestock translates to the ID,” Hastick explains, noting that a single piece of tubestock often has four or more different outer diameters.

Creativity comes into play as well, Hastick adds. Indeed, the company has often capitalized on opportunities to use the machine for cavities that, on first glance, don’t lend themselves to the process. Consider a pen cavity with an undercut created by a logo on one portion of the ID. Although a split cavity design can release such an undercut during molding, rotary swaging cavities in the first place requires a consistent cross section. To get around this limitation, the shop might burn the logo into one half of a rotary-swaged cavity that’s been cut in two lengthwise, then marry it to another half that has no logo. Cutting a cavity in two removes steel, he explains, so ensuring a perfect fit requires splitting two swaged cavities off-center so that one (usable) half of each is slightly oversized, and scrapping the two smaller halves. Nonetheless, exact size, consistency from cavity to cavity, less polishing, and less risk of damaging sharp edges make this solution more cost-effective than producing them conventionally.

The shop has answers to other restrictions as well. All cavities require some degree of draft to ensure they can be pulled back away from the mandrel when the process is complete (0.001 inch of draft per inch of stock is more than adequate, but the company has also worked with less, he adds). Material flowing from the larger, back end of the mandrel toward the smaller front end doesn’t wrap perfectly over portions of the mandrel that step down at an angle of more than about 15 degrees, Hastick says. Instead, it tends to leave a rounded void. As a result, the Cavaform machine typically isn’t a good fit when diameter changes create sharp corners and angles, at least not in its typical configuration.

However, the rotary swaging machine isn’t always in its typical configuration, in which the mandrel and blank are held in the back-pressure rod for what Hastick calls a back-pressure hit. The shop has also developed another option: the pusher hit, which involves mounting mandrel and blank in the pusher rod instead. Although the direction of material flow is the same in either case (opposite the feed), reversing the setup ensures material forms toward the larger-diameter back end of the mandrel—and thus, directly into any sharp corner and angle geometries.

Other limits aren’t as restrictive as they might initially appear. For instance, blind cavities are usually not an option unless the blind end is rounded, Hastick says (test tubes are a common example). However, cavities without rounded ends can employ gate gaps and telescoping shutoffs instead. In addition to enabling the shop and its customer to reap the full benefits of Cavaforming, these components are easy to replace when worn.

Driving Higher Standards

Massie emphasizes that the impact of this niche process on the rest of the shop extends beyond improved workflow. It’s shaped the company’s identity as well, particularly its approach to quality control. When the shop got its start in the late ‘70s, ±0.0002-inch tolerances and 4-micron surface finishes far exceeded even the most stringent industry expectations, he says. The case was the same with the capability to consistently achieve process capability index (Cpk) values greater than 2, and sometimes as great as 4 (most customers today expect only about 1.33, he says). Before long, however, customers naturally came to expect these levels of precision regardless of whether the job required it or was even suitable for Cavaforming. “Just by default, the quality of cold-formed cavities set a high benchmark for us over the years and really shaped our mentality,” Massie says.

For example, full volumetric cavity inspections have been “part of the culture” at this shop for decades, Massie says. Compared to measuring only “end to end”—that is, ensuring correct dimensions on both parting lines—Cavaform personnel drop various-sized ball bearings into both Cavaformed and EDM’ed cavities, then polish as necessary to ensure consistency throughout the entire length. The shop also inspects first-article cavities and other components to serve as validated masters. This isn’t a role played only by the quality control department, but also by every department on the floor, which checks part dimensions at dedicated stations after every stage of manufacturing. Each inspection is conducted twice, by two different personnel, no matter how elementary the measurement. This “buddy” system helps avoid mistakes. More importantly, it helps eliminate distinctions between EDM-burned cavities and those formed via rotary swaging, and in Massie’s view, that’s the true measure of Cavaform’s success. “We can’t treat work any differently based on how it’s processed,” he says. “Everything is held to the same standards.”

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreTips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More