Shops continue to adopt intelligent manufacturing principles that require connection and communication of data across all machine-tool, sensor and human resources. This data creates a virtual model that tests scenarios to improve uptime and throughput and to predict and better manage production capacity and estimated delivery times. The user also can plan and check continuous improvement activities against this model, which results in more efficient and profitable shops without costly trial and error. The more data that is collected, the more robust the virtual model.

Many moldmakers are already investing in intelligent manufacturing because the promise of improved product accuracy with less re-work and scrap is hard to ignore. Plus, better use of resources results in more on-time delivery and fewer overtime costs.

As shops continue to invest in the infrastructure to support this initiative, they usually focus on process data, such as machine uptime, tool life, cycle time and machine utilization. This information is extremely important to collect, but often other vital information is overlooked. For example, the length of time it takes to machine a mold component is important, but does that mold component meet the customer’s specifications?

To put it another way—making more parts faster and cheaper is great, but it does not matter if the parts are out of print. Collecting and using measurement data is just as important as process data. Not only does this ensure that mold components meet the customer’s needs, it makes it possible for companies to reduce scrap and rework.

As shops continue to invest in the infrastructure to support this initiative, they usually focus on process data, such as machine uptime, tool life, cycle time and machine utilization. This information is extremely important to collect, but often other vital information is overlooked.

Intelligent Moldmaking

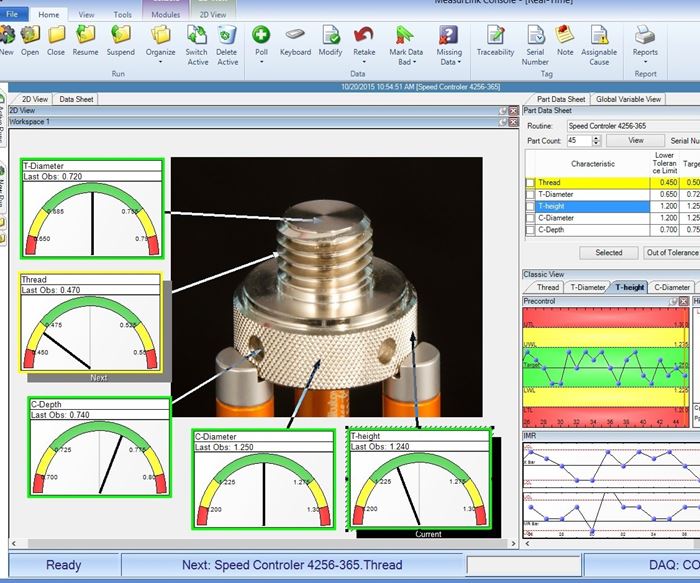

Data collection and real-time statistical process control (SPC) software collect data from most gauges regardless of sophistication or brand. The software then communicates the data to the same infrastructure as the rest of a shop’s connected devices. Here are a few eexamples of ways that moldmakers can use this tool to maximize intelligent manufacturing.

Moldmakers use several techniques to produce their products, such as CNC machining, additive machining, EDM and wire cutting. Many mold components also require surface treatments and polishing. A great variety of metrology equipment is used to measure these components. However, too many shops do not use this data beyond verifying part conformance.

Moldmakers should use data collection and real-time SPC software to collect measurement data and then relay it back to the CAD/CAM software to refine part programs, which ultimately yields more accurate parts. Many moldmakers are using software to increase CNC programming accuracy and throughput, but there are a large number of variables to take into account when machining complex molds. Many of these programmers are finding that the finished mold does not always match the model.

Some operators use in-machine probing to measure and compensate for this inaccuracy, but not all machine tools are fitted with this type of technology. Real-time SPC software can collect data from many sources, including coordinate measuring machines, non-contact and vision metrology and traditional hand tools like calipers and micrometers. This flexibility eliminates the need for new equipment investment as it enables users to begin this type of activity using existing gauges. All of this data can then be compared to the mold’s specifications and sent back to the CAD/CAM software to compensate the program.

Data collection and real-time statistical process control (SPC) software collect data from most gauges regardless of sophistication or brand. The software then communicates the data to the same infrastructure as the rest of a shop’s connected devices.

Measuring mold components before and after polishing can tell machinists how much material to leave for surface treatment. Polishing is required to meet stringent surface finish specifications, making it a very important part of the moldmaking process. However, multiple operators typically perform this process by hand, and each polisher may remove different amounts of material as they perform their work, despite having proper training and employing standardized techniques.

This can result in molds producing subtly different parts and inconsistencies that do not meet a customer’s requirements. The solution is measuring samples before and after each step of the polishing process to determine the amount of material that the polishing removed. Real-time SPC software collects and filters this data by the individual worker, which makes it possible for machinists to compensate for the exact amount of extra material that an individual polisher removes as they perform their work. This yields more consistent molds and less rework.

Having all of this data in one platform also facilitates simpler integration with ERP software. As moldmakers collect more measurement data from a greater variety of sources, data management becomes tedious. Many shops integrate this data into their ERP systems expecting this consolidation to reduce their workload. However, a typical manufacturer has many metrology equipment brands at various levels of sophistication and age, each with its own communication method, ranging from a simple USB output and RS232 serial communication to PC-driven gauges that save data as files. This variety can be time consuming and expensive to integrate into a system that is not designed to collect metrology data.

Real-time SPC software is designed to perform this task. With real-time SPC software, any device with output can collect measurement data. Operators can even use non-digital gauges with data entered via a keyboard. The ERP software can then harvest the entirety of this data from one source, the SPC software’s structured query language (SQL) database. This requires only a single integration, saving ERP costs and reducing the effort required to consolidate the data.

This next revolution in industrial technology requires tools like real-time SPC software to help moldmakers achieve intelligent manufacturing.

About the Contributor

Jeremy P. Banks

Jeremy P. Banks is a data management sales specialist for Mitutoyo.

Related Content

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreHow a Small Programming Change Cuts Cycle Time in Half

Overriding the CAM system when milling a series of lifter pockets helps to improve metal removal rate and increase feed rates.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreFour Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read MoreRead Next

Polishing Requires Local-Level Communication

A focus on machining and measuring when polishing saves time and improves part quality.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More