On-Machine Probing Technology for Mold Manufacture

Decision points to help you select the right probing system.

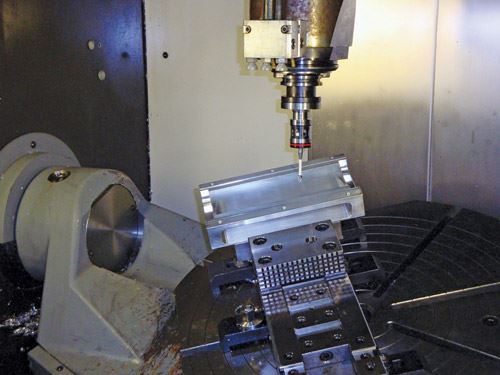

On-machine probing is a rapidly evolving technology that can impact significantly both productivity and quality in high-value moldmaking operations. Today, users can choose from a range of contact and non-contact sensors; several different wireless communication methods; and systems that deliver a spectrum of functions ranging from simple presence detection to sophisticated precision dimensional and geometric measurements of tools and workpieces.

Selecting the right probing system for a specific application starts with defining exactly what the probing system is expected to do, and then evaluating the various combinations of options to arrive at the most cost-effective solution. Here are some of the basic decision points.

Touch or Non-Touch

To confirm tool presence or measure tools on the machine, the fundamental choice is between a mechanical touch setter and a non-contact laser-based system. Both have their own strengths and weaknesses.

Touch setters are widely used for tool setting applications, length and diameter measurement of rotary tools and tool breakage detection. Today’s products are rugged, precise and reliable under the most difficult conditions. Because they depend on physical contact, however, tool speeds generally have to be limited to less than 500 rpm during measurement, and they will not reliably detect broken inserts on multi-insert cutters.

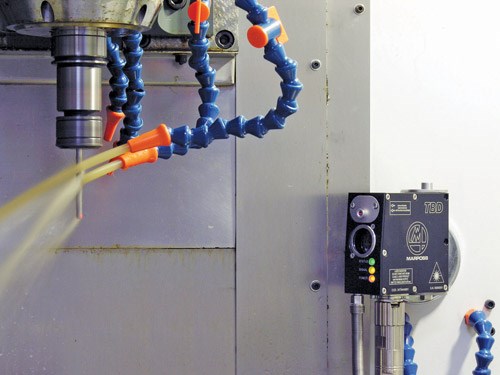

Laser systems, on the other hand, can reliably measure rotary tools at cutting rpm. This has the advantage of including any speed-related runout in the measurement. They are also able to detect broken inserts.

Until recently, laser systems often have been adversely impacted by reflections from coolant droplets in the air or on the tool, but manufacturers have developed solutions to this problem. For example, some laser probing systems are equipped with a shutter to protect the lenses when they are not in use and also surrounds the lens with a series of air jets that provide a tunnel of air around the laser beam. This system uses an intelligent processor that is programmed to reject false triggers from coolant droplets on the tool.

Other options include touch-type and simple laser systems designed specifically for tool breakage detection for solid tools like drills and end mills. These are essentially go/no-go systems with limited tool measurement capabilities.

The advantage of a laser tool breakage detection system over contact-type tool presence detectors is speed. They can be used during rapid traverse and typically have cycle times of 2 to 3 seconds. A contact sensor, on the other hand, typically requires 10 to 15 seconds to perform a tool breakage check. A more sophisticated laser system will perform the tool breakage check and check the profile of the tool—including the individual inserts on a multi-insert tool in the same 2 to 3 second cycle.

A contact tool detection and/or measurement system is the slowest of the three. A dedicated laser tool breakage detection system is faster, but provides limited or in some cases no measurement capabilities. Finally, a sophisticated laser system equals the speed of the dedicated tool breakage detection while providing both detection and comprehensive measurement data.

Wireless Type

Spindle touch probes are used for setting up fixtures and parts on the machine and for checking part details without having to remove the part from the machine. There are three basic wireless technologies available today for use with spindle touch probes: High-Frequency (HF), Infrared (IR) and Radio Frequency (RF).

HF is the oldest technology. It uses a single receiver mounted at a fixed location. HF is being overtaken by IR and RF, particularly on machining centers with more than three axes. IR is a line-of-sight technology that is very popular on small horizontal and vertical machining centers. It is not generally practical for machines with five or more axes because these applications require multiple receivers as line-of-sight becomes an issue.

RF communication technology is omnidirectional. A single RF receiver can handle inputs from a machine with multipe axes, or from multiple probes in the machine without any line-of-sight issues. Today there are RF systems with a combination of BlueTooth® and WiFi capabilities that allow them to detect and change frequencies automatically to avoid interference from other devices in a plant environment.

The latest RF systems operate on a frequency band that is available worldwide. That means they can be set up and programmed by the manufacturer anywhere in the world and will meet regulatory requirements at the customer location no matter where that might be.

The Bottom Line

Even the simplest on-machine probing system can deliver significant value by simplifying and speeding part setup, detecting a wrong, broken or missing tool, and stopping a machining process before the workpiece is damaged. A laser monitoring system can increase productivity by measuring tools on the fly at the rpm of the cut, and thus reduce runout and blending errors. However, on machine probing has benefits beyond the obvious ability to detect and measure tools. Perhaps the most important bottom line impact of an on-machine probing system lies in its ability to perform on-machine workpiece inspections that are normally done on a CMM. That, of course, requires a properly calibrated and properly maintained machine tool, but the investment can be highly productive.

Today, a finished or semi-finished workpiece is routinely unloaded from the machine tool and moved to a CMM for inspection. The machine tool typically sits idle while the inspection takes place. If errors are found, the workpiece is then returned to the machine, re-fixtured, re-aligned and re-machined. Under the best of conditions the machine tool has been non-productive for at least four or five hours, often longer. If the workpiece is inspected while it’s still on the machine, however, only the actual inspection time is non-productive.

In practice, this technique yields the greatest returns if the on-machine inspection is limited to the most critical points on the workpiece. A full customer-specified CMM inspection of the finished part will still be required in most cases, but the likelihood of that inspection finding anything critical requiring re-machining may be greatly diminished by on-machine probing.

Summary

On-machine probing technology has come a long way from the first fragile touch probes. Today, it is a vital tool that can impact both the productivity and profitability of the mold industry’s high-value machining operations.

Related Content

5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

Read MoreMachine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreLine Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

Read MoreHow to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

Read MoreRead Next

Machine Tool Probing for Moldmaking

It’s time to look at the probe as a device that can literally be used as a Virtual Operator to perform many of the everyday, time-robbing processes that eat into your profitability.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More