Moldmaking Reports Broad-Based Activity Expansion

Third quarter ends on a high note with expanding backlog, production, export and employment activity.

The GBI: Moldmaking reported an accelerating expansion in overall business activity during September; however, this was in part driven by an all-time high level of supply chain disruption.

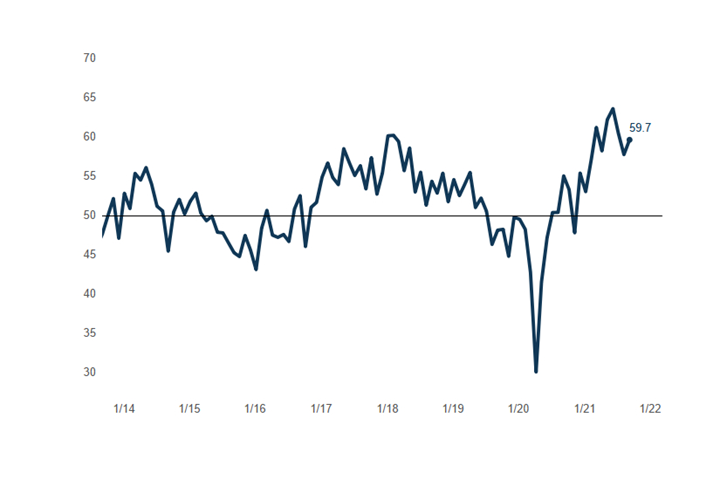

The September Gardner Business Index (GBI): Moldmaking closed out the final month of the third quarter at a 59.7 reading. The near two-point gain was the result of expanding activity in backlog, production, employment and export orders activity. The overall reading, however, was inflated by a 10-point increase in the supplier delivery reading, taking it to a new all-time high. (Recall that higher supplier delivery readings correspond with worsening supply chain performance.) An accelerating expansion in export orders helped to soften the month’s slowing expansion in total new orders activity.

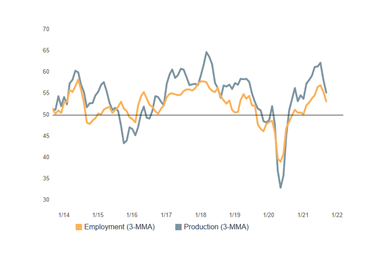

The third quarter of 2021 reported sequential months in which a shrinking majority of moldmakers reported expanding or unchanged payrolls. During the quarter, constrained employment levels weighed heavily on production activity and sent backlog readings to near all-time highs.

The third quarter brought the problem of a diminished labor force into sharp focus for the industry as a scarcity of new hires resulted in sequential months of slowing growth in payrolls. These latest labor challenges, coupled with the industry’s ongoing supply chain problems, weighed heavily on production activity which reported lackluster readings as the quarter progressed. This shortage of both materials and labor resulted in a “production deficit,” measured as the vertical gap between total new orders and production readings. However, it is the persistence of this gap at five months and counting which is having the greatest impact on the industry.

Related Content

-

Moldmaking GBI Returns to Contraction After One-Month Respite

After a challenging move into the 50s in March, the April GBI returned to a mostly consistent state of contraction, the result of recent market dynamics.

-

Moldmaking Industry GBI Contracts for Four Months Straight

The GBI Moldmaking ended the month at 45.8, down one point from June, with components contracting or nearing contraction activity.

-

May Moldmaking Index Trends Downward

Contraction, experienced by most May components, continues to be familiar territory for the GBI: Moldmaking Index.

.jpg;width=70;height=70;mode=crop)