Moldmaking GBI Returns to Contraction After One-Month Respite

After a challenging move into the 50s in March, the April GBI returned to a mostly consistent state of contraction, the result of recent market dynamics.

GBI: Moldmaking has returned to contraction mode, activity having dropped almost three points in April. Photo Credit, all images: Gardner Intelligence

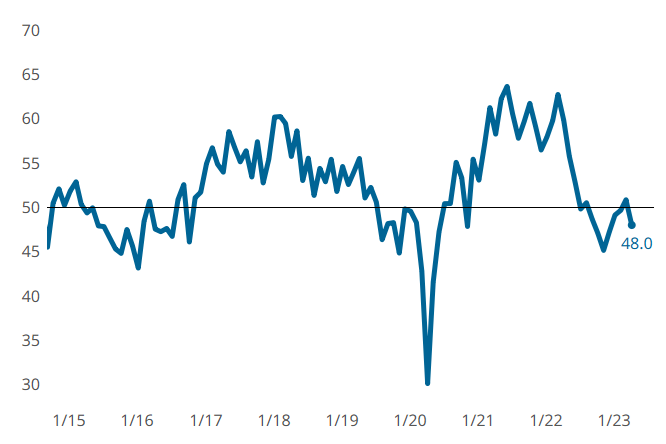

Now you see it …now you don’t — the expansion of moldmaking activity, that is. What was speculated in the March Gardner Business Index (GBI) Moldmaking as a likely unsustainable transition into growth territory materialized in April as it dropped almost three points to a reading of 48.0, contracting again after expanding (barely) for just one month.

That March’s small level expansion seems to have been a blip is not surprising in light of consistent contraction of moldmaking activity in each of the six months prior, combined with relatively recent market dynamics that include inflation, rising interest rates and bank failures.

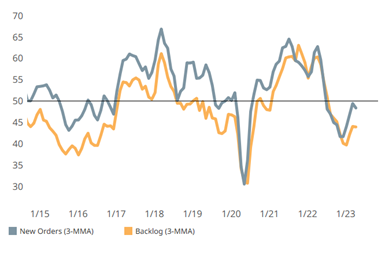

Backlog contraction in April was the same as in March, while new orders contracted a bit faster for the first time this year. (This graph is on a three-month moving average.)

April saw steady or downturned activity for all six GBI components. Two of these components, exports and backlog, continued to contract in April at rates similar to March, while new orders contracted a bit faster.

Alternately, production and employment expanded again, the former at a bit slower clip and the latter at about the same pace as March. Activity in both components may reflect, in part, holes dug during COVID-19. Specifically, supply chain issues during COVID limited production while health risks at the time reduced the size of the active labor supply.

For April, supplier deliveries continued on the path they started on more than a year ago, and that has been lengthening at a continually slowing pace. If the trend continues, deliveries will, in fact, shorten as suppliers are able to meet demand in terms of materials and timing.

Related Content

-

November GBI Saw a Drop in Moldmaking Activity

The moldmaking index experienced a high degree of accelerated contract, primarily driven by production, new orders and backlog readings.

-

Moldmaking Accelerated Contraction in June

June’s moldmaking index took a relatively steep downward turn, landing at a new low for the year.

-

Moldmaking Activity Accelerated Contraction in July

July’s moldmaking index accelerated contraction for the third month in a row, though the magnitude was considerably less than last month.