Take Time to Save Time: 6 Steps in Mold Design to Reduce Back-End Troubleshooting

Westminster Tool shares how the one week it typically takes to perform these six steps in the design phase can save three weeks or more in an overall tool build.

When you buy a mold, you’re not just buying steel — you’re buying parts that meet specified tolerances. Photo Credit, all images: Westminster Tool

When you go to a moldmaker, what are you really buying — just steel or something more? The reality is you’re paying for the plastic part, and not just any part, but a dimensionally stable component that will meet the part print shot after shot for the millions of cycles the tool will be running. With that in mind, why aren’t molders and moldmakers discussing plastic quality sooner?

Back in 2017, Westminster Tool implemented a more proactive plastic-quality design process. At that time, we looked at what we called our five “biggest losers.” These projects were our least successful regarding timing, budget and part quality. We took a deep dive into all of them to find the root causes of the problems, and what we discovered was that in all five cases, the crux of the issue was plastic part quality — issues with tolerances and dimensions that we easily could have avoided in the beginning if we had just had the right discussions with our customers.

As a result of that deep dive, Westminster Tool now completes six steps on every project during design: Compare 2D prints to 3D models; computed tomography (CT) scan existing parts if there are any; complete a dimensional risk analysis; understand quality expectations and Cpk goals; perform a Moldex3D simulation; and define and align quality plans.

Why is it important to take these steps early in the process? Since Westminster Tool initiated this new protocol, we have found that one week added in the design phase — how long it takes to complete these six steps — can eliminate more than three weeks on the back end in terms of troubleshooting, adjustments and more. In addition, the money and time expenditure to make an alteration to a mold design is far lower than having to make corrections to manufacturing. Since making these changes, our on-time delivery and successful initial first article inspections (FAIs) have drastically increased.

1. Compare 2D to 3D

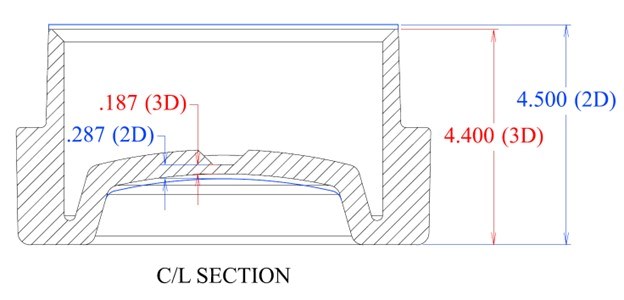

At the end of the day, the customer is paying for the plastic part’s dimensions and meeting tolerances and quality requirements. To accomplish that, one of the first things Westminster Tool does during design is to take the 3D model and fully dimension and detail that model to ensure it matches the dimensions on the 2D part print. Since that print is what everything will be measured to, it is the true definition of success. Putting this comparison into our process helps us to identify any risk areas where the plastic dimension in the 3D model does not match the 2D expectation for that part.

Take care to ensure that your 3D model matches the part’s 2D drawings.

Alerting to any discrepancies during the design phase greatly reduces lead times because 2D print changes typically require multiple approvals from the OEM level and can take upwards of two weeks. That’s not something you want to be waiting on at the end of the project during the inspection phase. In addition, thoroughly reviewing the part’s dimensions and tolerances provides a fundamental understanding of its ultimate fit, form and function.

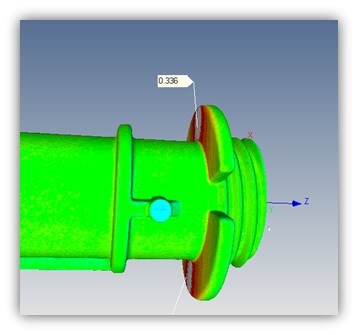

In red you can see a discrepancy from the part print, which ended up being draft that was added to aid in ejection. Without CT scanning, this would have been learned the hard way during sampling.

2. CT Scan Existing Parts

Any time Westminster Tool builds a mold for a customer looking to boost production or replace an existing mold for a current product, we send existing parts for a CT scan. Why? Because over the life of a tool, many adjustments and changes can be made to the steel that are never noted or make it back to the original tool design. For example, draft or polish is added for ejection, or additional crush is added to overcome flash. Over the life of a tool, an array of challenges can be addressed but never actually make it back to the original part or tool design.

By CT scanning existing parts up front, we can build reality into our tool versus uncovering it the hard way during mold trials. With most capacity tools, those lessons have already been learned, and CT scanning the parts eliminates the time and cost of learning them all over again.

Since Westminster Tool initiated this new protocol, we have found that one week added in the design phase — how long it takes to complete these six steps — can eliminate more than three weeks on the back end in terms of troubleshooting, adjustments and more.

3. Conduct a Dimensional Risk Analysis

An internally created worksheet allows us to evaluate the risk level associated with any given plastic tolerance. Created using the "SPI Standards and Practices of Plastics Molders," this document analyzes a specific plastic material's ability to meet tolerances for various features. Every resin has its own shrink and warp characteristics further influenced by part geometry. Because of this, every material can potentially achieve a different level of quality.

If we find a specification that’s tighter than the fine or standard tolerance, that makes us aware of a risk that this particular tolerance will be difficult to achieve in the plastic that’s been chosen, based on the design of the part. That doesn’t mean we’ll try to open the tolerance or say we won’t meet it. Instead, it starts a conversation about what mitigation plans can be implemented to ensure we meet the customer’s quality requirements. Those plans could involve anything from steel-safe dimensions to designing inserts so that we could modify them and still use them in the tool without a big impact on cost and time.

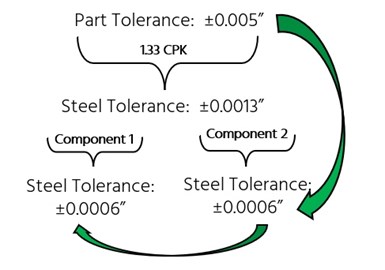

Ensuring steel is capable of holding the required tolerances is critical.

4. Cpk

Historically, if the tool builder isn’t performing mold validation or inspection services, Cpk (process capability index) isn’t something a customer would expect to ask or worry about. Holding 50% of the print tolerance for our steel tolerance should ensure the steel can hold that tolerance, cavity to cavity, over the tool’s life. However, when the customer wants a 1.33 Cpk or higher, that 50% of the plastic tolerance might not be good enough to satisfy quality demands over the tool’s life.

For example, a 1.33 Cpk tells us to not only use a more narrow margin of plastic tolerance for that dimension — ensuring that we’re tighter than that 50% — but it also ensures that the precision of the steel features we create is extremely accurate, eliminating one variable from all the variables in the injection molding process that could cause a dimension to be out of tolerance.

5. Simulate and Analyze

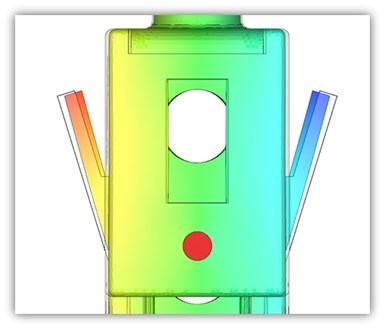

Westminster Tool uses Moldex3D flow simulation to compare what the molded part will actually look like to the 3D model, accounting for warpage and more.

Moldex3D is a flow simulation and analysis software allowing Westminster Tool to examine the entire molding process. Using this software not only enables us to design an effective and efficient tool but also helps us understand the final molded part quality based on that injection mold design. This also ensures that any design choices or proposed changes are data-driven and not just based on know-how or experience. Decisions around the size and location of gates, cooling channels and runners can be tested iteratively without cutting steel.

6. Align Quality Plans

Whether or not Westminster Tool is taking on inspection, we request the customer’s quality plan up front during the design phase. Typically, that quality plan includes the specific features and dimensions the customer is trying to hit and the tolerances and preferred measurement method. Understanding measurement methods sets up Westminster Tool for success by informing us how we’ll measure parts coming off the tool.

This could involve creating a fixture or designing a CMM program to take measurements. Aligning these methods with the customer during the design phase reduces any chances of delays at the end of the project. Even when we are just performing a first-parts-off-tool trial and sampling parts internally, we can inspect these first-off parts and ensure they’re meeting quality requirements right at our own press. This reduces the lead time involved in sending out parts for inspections, waiting for approval and shipping the tool.

Defining Success First

At the end of the day, it’s important to understand expectations for all parties involved to succeed. The OEM, contract manufacturer, tool builder and whoever else participates in the project must be on the same page about exactly what success looks like. If our definitions differ, time and cost will catch up to us eventually.

Here are the questions you can ask if you have access to a part’s quality plan.

- What is your requirement for first-off-tool?

- What is your requirement for mold factory acceptance test (MFAT)?

- Do you need to meet a Cpk? If so, how many shots are required for it?

- How are you going to perform Cpk inspection?

- Will there be any in-process checks required?

- Is there an acceptance plan your mold builder must meet before shipment?

In addition, here are some questions for capacity or existing tooling:

- When was the last FAI performed?

- How many versions of this part are on the market?

- What challenges did you have to overcome in your original MFAT?

- Do you have a log of tool history and modifications?

Remember to think about the end of the project at its beginning. That mindset will set you up for success by understanding the definition of success from the start and how you plan to measure it. Once you have that definition, you must consider any risks or obstacles that could keep you from achieving that it. Finally, your entire team must be willing to invest up front to minimize cost or time delays on the back end. A major shift like this can seem daunting for some companies, but getting support and buy-in from all personnel involved is key. Shifting the conversation about quality requires full transparency and open communication, but the benefits outweigh the challenges. The one week we have added to design has paid off on every tool.

Related Content

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreHow to Fix Predicted Warpage Before It Happens with Windage and CAD Model Morphing

Applying windage and model-morphing techniques saved toolmaker/molder Sturgis Molded Products the time, cost, headaches of multiple part/mold design iteration loops, cumbersome cooling fixtures, and long molding cycles.

Read MoreWhat Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreRead Next

Westminster Tool Partners with Sumitomo (SHI) Demag

The Connecticut moldmaker added a new all-electric Sumitomo (SHI) Demag press, boosting its mold qualification capacity and giving the machine maker a New England outpost for sales and training.

Read MoreWestminster Tool and Mantle Partner on 3D-Printed Mold Technology

The Connecticut mold maker will be one of two beta-testing sites for Mantle’s TrueShape metal 3D printer, with a medical device already borne out of an ongoing collaboration.

Read MoreWestminster Tool Wins 2021 Leadtime Leader Award

The Plainfield, Conn. moldmaker earned the Moldmaking Technology magazine award, which has been bestowed since 2003 to toolmakers that go above and beyond fast lead times and excel in all aspects of the trade.

Read More

.jpg;maxWidth=300;quality=90)