There is no doubt about it: More and more molds are being designed to include hot runner systems or hot sprue bushings. For those who build and run hot runner molds, it is not hard to see the reasons why. While expensive to build, hot runner molds can be more economical in the long run than their cold runner counterparts. Still, there are many hot runner holdouts, so it is time to build the case for transitioning from cold to hot runner molds.

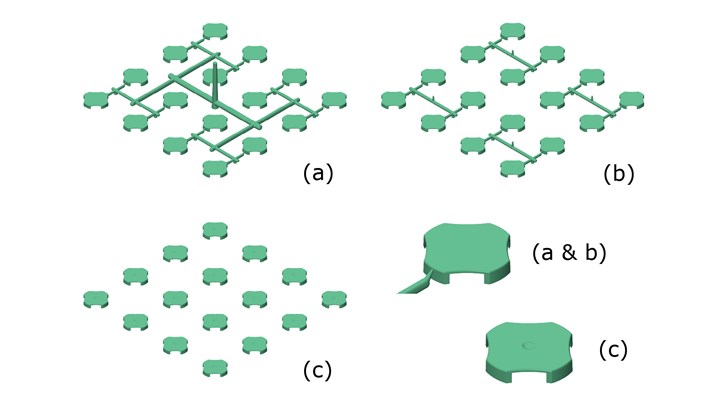

(a) Cold runner design — a shot weight of 59 grams and estimated cycle time of 30 seconds (b) hot to cold runner system — a shot weight of 37 grams and estimated cycle time of 23 seconds and (c) direct gate hot runner system — a shot weight of 26 grams and estimated cycle time of 19 seconds. Photos Credit, all images: PCS Company

Cold Beginnings

In the early days of injection molding, cold runners were the only method for delivering plastic to a mold that ran more than one part. It is a method still used today. Cold runners usually comprise two or three plates, and a nozzle delivers the molten plastic into the mold via a sprue, then through channels or runners that lead to the mold cavities that are then filled to make plastic parts. Typically, the sprue requires the most time to cool because it is usually thicker than the runners and parts.

Moldmakers and molders who use hot runner systems in their molds will be the first to disclose that it is often the most expensive part of the mold build. But they quickly add that it is worth the investment based on reduced cycle time, resin cost, elimination of post-processing, product lifecycle, etc.

Molders then must perform secondary operations, which begin with trimming gates, if necessary. Dealing with the runners and sprue requires the molder to perform post-molding operations such as regrinding and pelletizing, then mixing with virgin plastic, if the reuse of plastic is permitted. Unfortunately, many engineering and medical applications do not permit regrind reuse or only allow a small percentage. Any remaining scrap plastic must be disposed of or sold for pennies on the dollar.

Cold runner molds do have their advantages. They are simple in design, relatively inexpensive to build and easy to maintain. However, hot runner molds have proven to be a much better alternative for most applications.

Why Choose Hot Runners?

Moldmakers and molders who use hot runner systems in their molds will be the first to disclose that it is often the most expensive part of the mold build. But they quickly add that it is worth the investment based on reduced cycle time, resin cost, elimination of post-processing, product lifecycle, etc. Meanwhile, hot runner holdouts are skeptical, wondering why they should add thousands of dollars to the upfront cost of a mold when the cold runner system gets the job done. So, let’s examine the facts.

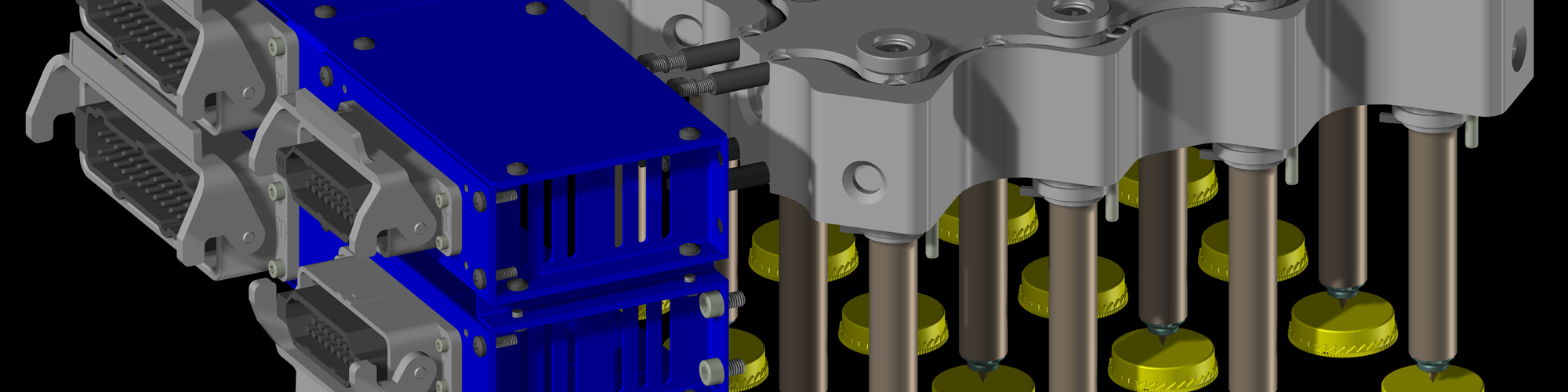

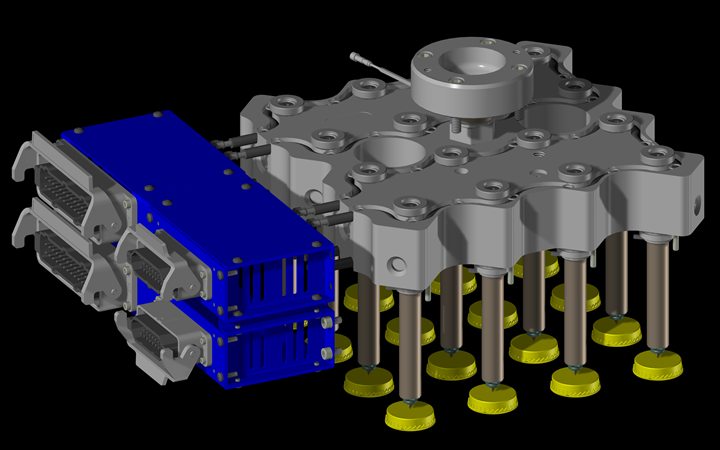

A 16-drop hot runner system with direct gating.

Hot runner advantages include:

- Hot runner systems deliver molten plastic directly to the gates and into the mold cavities without the need for runners and a sprue. As a result, material waste and secondary operations are virtually eliminated, which reduces production costs.

- Cycle time is reduced. The sprue and runner no longer control the cycle time because the plastic does not have to travel as far to reach the cavities, enabling the part to cool faster. Additional cycle time savings are gained from hot runner nozzles maintaining processing temperatures right up to the gate, enabling faster filling and a 100% packing rate (no shearing or short shots).

- Part quality is improved because resin characteristics remain intact.

To illustrate further, a long-time molder ran a single-cavity mold using a cold sprue with a branch of a runner to make little nylon wheels. The customer ran 21 seconds to fill each part and scrapped the sprue and runner with every cycle. Then he would machine each wheel because he worried it wasn’t truly round, adding yet another step to the production process.

Finally, he was convinced to try a hot sprue bushing and immediately saw significant savings on material by direct gating the hot sprue to the part. In addition, the gate location changed from the periphery to a central location on top of the part. As a result, he could reduce his cycle time from 21 seconds to 15 seconds and no longer needed the secondary operations because of the more balanced gate location, freeing up manpower for other work.

Thermal Gate Vs. Valve Gate Hot Runner System

Thermal gate systems are the most common and economical. Thermal describes the type of shut-off used to stop the flow of plastic into the mold cavity. The small gate freezes as the part cools and stops the plastic flow so that the part can be ejected. If the gate is too big, the thermal seal will fail, causing stringing or drooling.

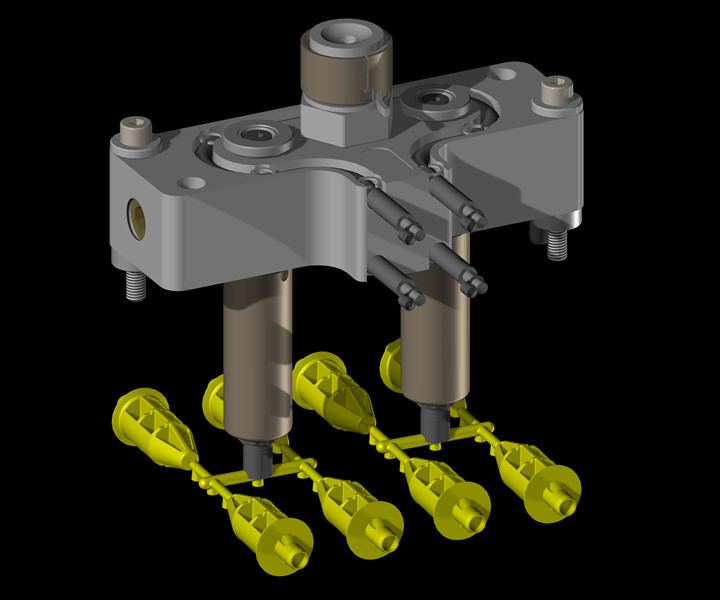

Valve gate systems use either pneumatic, hydraulic cylinders or servo drives to actuate a valve gate pin to control the flow of plastic into a cavity, giving the molder more control over the molding process. Several advantages can be gained by using a valve gate system, including enlarging the gates to fill the part faster, decreasing cycle times.

The moldmaker is better positioned to determine which option is most cost-effective.

Another benefit is there is no apparent vestige. The valve gate makes a clean break from the part, leaving only a fine witness line from the valve gate pin. This makes the valve gate system a great option for cosmetic parts that are decorative, as well as for medical applications where gate vestige is not allowed.

Valve gate systems are more expensive than thermal gates because they require more components to actuate the valve pins. Still, they can be ideal for more complex molding applications, including molds that demand sequential filling.

Both thermal and valve gating systems are available for single and multicavity applications. In the single-cavity mold, a hot sprue bushing will be used. In a multicavity mold, the system requires manifold(s) and nozzles within a hot-half stack. No matter the cavitation, there is always material savings.

Making the Change

The first step to switch over to a hot runner mold is to perform a design analysis to ensure that a hot runner is appropriate for the application. For example, determine if the material being molded is suitable for a hot runner design, which is an essential consideration whether the mold is new or being retrofitted. Though most resins are amenable to hot runner usage, there are exceptions. Consult your material supplier for their recommendations. If a hot runner system is deemed feasible, determine whether to go with a thermal gate or valve gate system. This is a good time to seek input from a knowledgeable hot runner supplier who can recommend suitable options. Most hot runner suppliers also offer Moldflow analyses to ensure the hot runner system is balanced and to assist with a part fill study.

A hot-to-cold runner system with only two drops for an eight-cavity mold.

Crunching the Numbers

Costs are determined based on the hot runner requirements. A single-cavity mold will typically require a hot sprue bushing and those calculations are straightforward. However, when the mold has more than one cavity, there are a few factors to consider.

- Is direct gating required? If so, a complete hot runner system with one nozzle for each cavity is necessary.

- A hot-to-cold runner system can be used where side gating is permissible. This system feeds into a cold sub-runner, reducing the number of nozzles (or drops) required. As every drop adds to the cost of a hot runner system, this is a more economical option.

- There are three options for building a hot runner system:

- Purchase the system as a complete hot half (manifold, nozzles, plates wired and assembled).

- Some vendors offer pre-wired systems, with manifold, nozzles and electrical connectors wired and assembled as a single unit. The plates and machining are the responsibility of the moldmaker, for which the hot runner supplier usually provides drawings. This can help lower time and costs.

- The manifold and component option requires the moldmaker to purchase all of the necessary components to build the hot runner system. The moldmaker will also have to machine the plates and assemble and wire the system. Again, the hot runner supplier usually provides drawings for plate machining.

The moldmaker is better positioned to determine which option is most cost-effective.

It should be noted that it is not unheard of for molders to use cold runners in prototype or short-run production molds, particularly when trying out a new product design. However, once that design is perfected, a larger production mold would include a hot runner system or hot sprue bushing to produce the product more rapidly and cost-effectively in much larger quantities.

Related Content

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreFundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read MoreRead Next

Choosing Between Cold and Hot Runner Systems

Get all the facts before selecting a runner system solution.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read More7 Key Advantages of Hot Runner Systems

While both hot runner and cold runner systems have their benefits, for design flexibility as well as reduced cycle times and costs, hot runner systems will probably be the better choice.

Read More