Choosing Between Cold and Hot Runner Systems

Get all the facts before selecting a runner system solution.

The injection molding industry generally perceives companies that use hot runner systems as more advanced than companies that use cold runner systems. Often, shops make the decision to use a hot runner without considering a cold runner’s possible cost and quality benefits, or management dictates the decision as part of a cost-savings initiative.

On the surface, using a hot runner seems perfectly valid. Hot runners require less material, which decreases part cost. However, hot runners can actually create more scrap because of downtime, leaks or other issues. The savings on paper do not always add up to real money in the bank.

This is an interesting and often debated topic during our training and education courses. Many of our students come from companies that only run hot runners. Others run a mix of hot and cold runners in their facilities, and they have one thing in common: they all complain about their hot runner systems. The complaints are often about temperature uniformity, quality, support, downtime, maintenance and the narrow process window they often run into with these systems.

Digging into the design of a hot runner system reveals all the places from which potential issues could stem. Understanding the source of these hot runner issues and their impact on a shop’s bottom line can help a shop determine if a cold runner is the better option for some of its applications.

Evaluating Sources of Variation

Here is a checklist of several common hot runner challenges and sources of variation to consider in deciding between a hot runner or cold runner solution:

- High pressures at assembly points

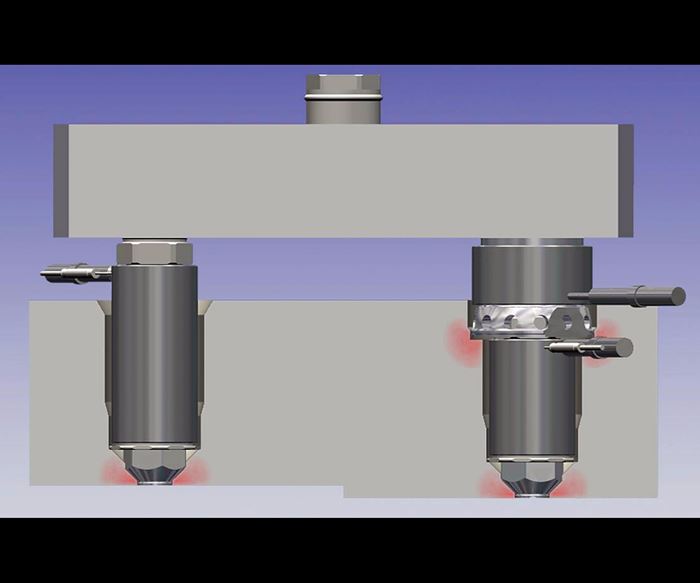

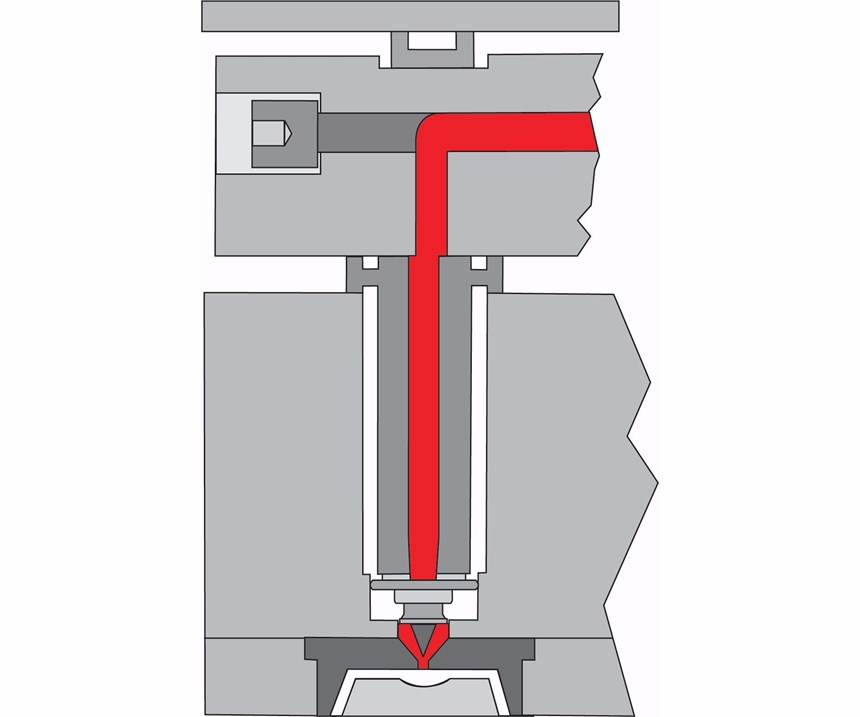

- Required co-existence with a cold mold and platens (see Figure 1)

- Gating issues (for example, cooling, or molten material on one side and frozen material on the other, clogging, drooling, stringing and control systems)

- Thermal expansion and alignment of drilled channels (see Figure 2)

- Stack-up tolerances

- Hang-up/dead flow in channel geometry

- Higher skill-level requirement

- Smaller shot size yielding less velocity control during injection

- Cycle interruptions, which potentially create more issues

- Leaking issues

- Controller performance

- Heater resistance

- Thermocouple placement and contact

- Dimensional variations of the gate tip

- Nozzle bore details

- Cross drill alignment

- Valve pin seating

- Flow imbalances

- Power consumption

Evaluating Costs

A hot runner is an investment, and it should be viewed accordingly. If the investment does not meet the criteria for payback over a desired return on investment timeframe, then a cold runner may be a better option. When evaluating the cost of a hot runner system, consider both the direct and indirect costs.

Direct costs include the hot runner system, spare parts (tips, heaters, thermocouples and nozzles) and controller components. The indirect costs include maintenance issues, residence time, color changes (time, material, purging compound), potential variation in temperature throughout production, effect on part quality and process window and training requirements.

The Cold, Hard Facts

In many cases, the cold runner system is a more viable option. In some applications, it may provide a mold and a process that is capable of producing higher-quality parts. Although this is counter intuitive to what many think, the fact remains that with a cold runner, a mold designer controls the design, and a mold builder controls the manufacturing of the system. This means they can more easily see and measure the channels in a cold runner system over the channels in a hot runner system, which gives them the ability to inspect the cold runner system for variations. If they find a problem or need to change runner sizes or gate location (or locations), they can do this much more easily in a cold runner than they can in a hot runner system. This is because the hot runner gate drop locations are fixed for a given manifold.

The advantages of cold runners include:

- Lower initial investment (no system or electronic controls to purchase).

- Flexible gate locations and design options.

- Easily changeable gate locations and designs.

- Better shot control because of larger screw strokes.

- Easier steel measurement.

- Simpler variation diagnosis because of less complex melt delivery systems.

- Fewer thermal variations in the process, because thermocouples, heaters and controllers are not required.

- Easy rheological control implementation.

- Freedom from color changes in the cold runner section, since they are ejected every cycle.

The challenges of cold runners include:

- A higher material cost than that of a hot runner.

- Runner and regrind handling.

- Limited cycle time if the runner is sized improperly.

- Reduction in the shot size capacity that is available for parts, which the runner volume causes.

- Increased clamp tonnage considerations for the projected area.

Runner Conversions

Many companies that have participated in our education courses have used both hot and cold runner systems. Some companies converted from cold runners to hot runners. Others made the same switch only to return to cold runners, because hot runners presented quality and cost issues for the parts of those particular companies.

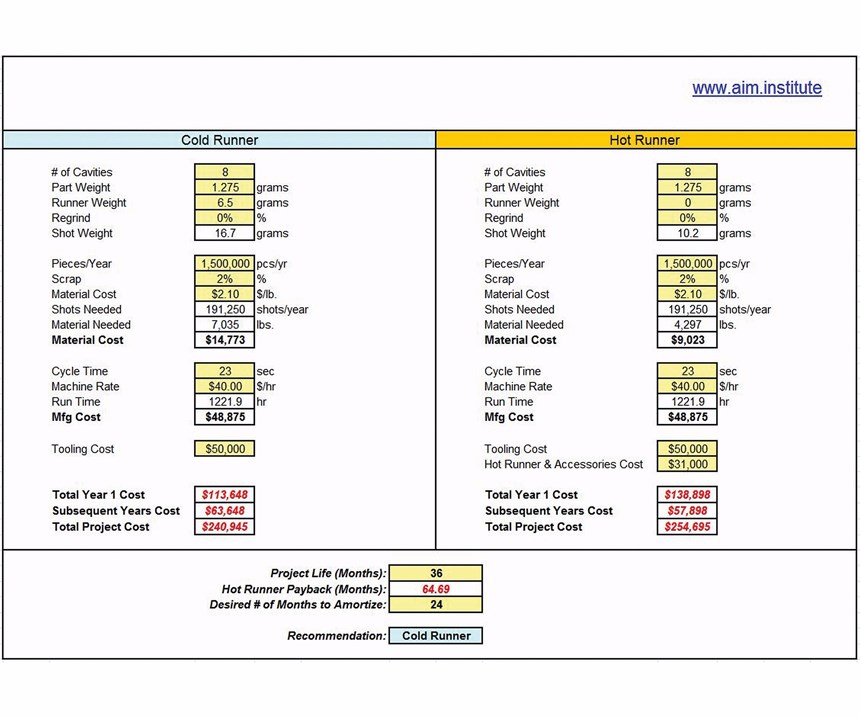

Figure 3 is a cost analysis for a product that a manufacturer was going to produce in an eight-cavity mold for which the purchaser desired a two-year return on investment. This example strictly examines the material savings from the use of a hot runner in comparison to the use of a cold runner. Some would argue that hot runners provide additional savings, such as cycle time, energy, clamp tonnage and so on, and they could be right. However, those benefits are not a guarantee in every case, so we excluded them from this cost analysis. We encourage students to develop a spreadsheet like the one in Figure 3 and alter the numbers to determine what they must achieve to meet their return on investment requirements. They should then make a judgement on whether those improvements are actually viable.

The example shows that the cold runner is the better option for that particular application. If it is necessary to evaluate additional material volume cost cuts, shops should think about implementing the following design steps:

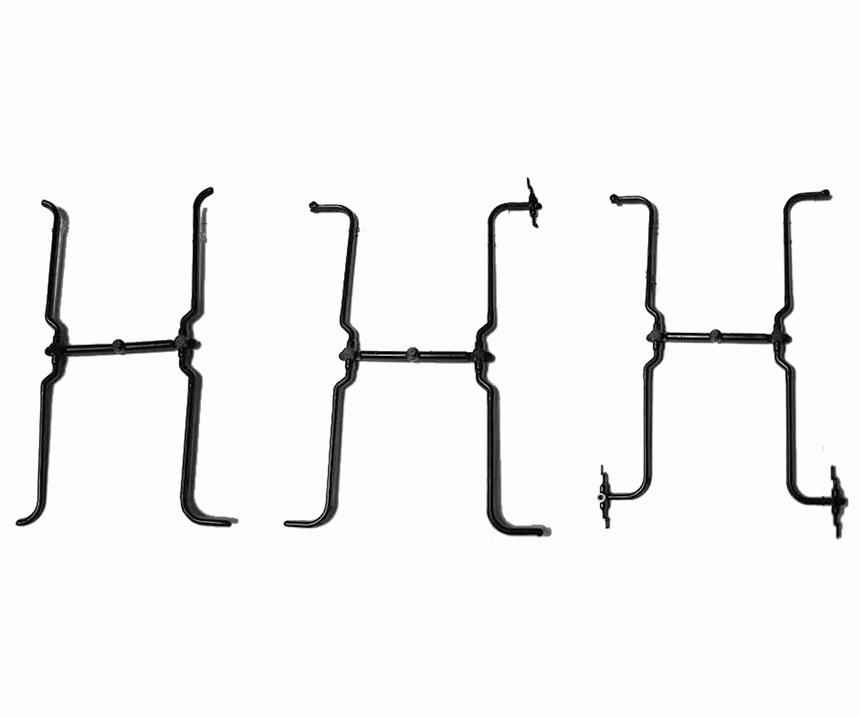

- Incorporate a hot sprue, but be careful of the type of tip used, as it may create other flow variations. Some gate tip types used in the hot sprues and hot runner nozzles, for example, can alter the mold’s filling, packing and material property balance. Figure 4 on page 24 shows a single hot sprue feeding a short shot of a cold runner system. The hot sprue was turned to three different orientations. As a result, the filling of the runner changed three different times. Now imagine that this runner represents a direct-gated part. The part quality is now dependent on the orientation of the gate tip, which alters the filling pattern, the orientation of the polymer and fillers and the temperature and pressure distribution within the part. Then imagine a multi-drop system in which each gate tip is in a different location, so each part or parts fill out of each drop differently, which creates variation in the process and molded part.

- Consider using a two- or four-drop hot runner system instead of a full eight-drop hot runner system, as the latter lowers the initial investment, eliminates a portion of the cold runner system and maintains flexibility in the gating.

- Engineer the cold runner system to minimize material volume and cycle time.

- Design proper cooling of the thicker cold runner regions to minimize the impact on cycle time.

Of course, there are plastic parts that could not be molded competitively, or even at all, without the use of a hot runner system. The purpose of this article is to get shops thinking about their molds, so that they can properly evaluate and justify their next runner selection.

About the Contributor

David Hoffman

David Hoffman is the director and instructor for plastics education and training for Beaumont Technologies, Inc.’s American Injection Molding Institute (AIM).

Related Content

Tackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreEditorial Guidelines: Editorial Advisory Board

The Editorial Advisory Board of MoldMaking Technology is made up of authorities with expertise within their respective business, industry, technology and profession. Their role is to advise on timely issues, trends, advances in the field, offer editorial thought and direction, review and comment on specific articles and generally act as a sounding board and a conscience for the publication.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreRead Next

Switch to Hot Runners Pays Off for Pulley Molder

Retlaw has cut scrap, improved part quality and slashed cycles since adopting hot runner technology.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More