Chatter Myths: Pieces of the Puzzle in Maximized Machining

In today's moldmaking market, selecting proper parameters of the machining operation to avoid.

Current machining in today's moldmaking market is extremely competitive. One way to achieve an edge over a competitor is to improve machining conditions by intelligently selecting proper parameters of the machining operation to eliminate unwanted conditions such as chatter. By doing so, substantial savings of machining are achieved because chatter is the most problematic and limiting factor of machining, especially with high spindle speeds and long reach cutters. Chatter does occur at standard conventional speeds, although it is more distinct and destructive with higher spindle speeds. This article will discuss the milling process of machining and rpm rather than the depth-of-cut, feedrates and other parameters.

RPM

The one parameter that affects chatter conditions the most is rpm; it also happens to be the quickest and easiest parameter to obtain or change to maximize the machining operation. Actually, one can program the best rpm of a machining operation before even taking a cut if the right equipment is used or it can be adjusted during a cut. There also are chatter control devices that work directly with machine controllers detecting chatter during the machining operation; they automatically adjust the rpm to a more desired speed and begin cutting again. These items are required to effectively machine at maximum potential, but understanding chatter is the first thing to know in order to use any of these types of equipment or methods in the future. This brings us to chatter myths.

Chatter is a very exciting condition to work with and normally difficult to effectively eliminate or deal with. Unfortunately, it is surrounded by myths in the industry, which misguide, confuse and diminish machining operations causing substantial financial loss with the machining operation because it is not being maximized. Many believe rpms need to be slowed to eliminate chatter, when it is most probable that rpms need to be increased, which increases feedrates and depth-of-cut when the right rpm is used. In order to get around chatter, we must first understand what it is, what causes it and the benefits of eliminating it.

Chatter Facts

Chatter is the most problematic condition of a machining operation. The cutter, holder, spindle or machine self-exciting causes chatter, resulting in very high chip thickness variations as each tooth of the cutter passes during a cut (also referred to as regeneration of waviness). It continues to grow until the chip thickness is exceeded and the cutter jumps out of the cut. Most confuse chatter (self-excited vibration) with forced vibration. They are not the same; they only appear similar. The problem you hear or see with the machining operation may not be chatter at all—it could be forced vibration. Forced vibration is a condition that can be addressed by balancing or feedrate change. Self-excited vibration is the root cause of chatter. It is the villain that most often creates the unstable machining process. It is usually the result of a mismatch between the frequency response of the spindle and stackup (toolholder assembly).

By eliminating chatter the following conditions will result:

- Stable cutting speeds that produce maximum use of power, metal removal rate and depth-of-cut

- A 30 percent average increase in MRR that can be obtained by knowing the correct rpm

- Reduced or eliminated part tryout, second operations and scrap parts due to unstable machining conditions

- Significant reduction in machining times—30 percent or better increase in cutting tool life

- Reduced wear and tear on machine components such as spindle bearings, machine guide ways and servo drives

Three Types of Vibration

Three types of vibration that could occur in a machining operation are free vibration, forced vibration and self-excited vibration. Free vibration involves a characteristic natural vibration. It is like a drum, guitar string or transient motion at the start and end of a machine motion. This type of vibration is usually problematic and has little practical significance. Theoretically, it reveals the natural frequency and damping ratio of the system (see Figure 1).

Forced vibrations are produced by a periodic force acting on the system. A harmonic force has a singe frequency f and it excites vibration x with exactly the same frequency. It has a deterministic, steady vibration as well as an unbalanced shaft or rotor. It can be a problem, but it is limited due to high stiffness of machine setups. In machine tools, we encounter forced vibrations excited by unbalanced rotating masses (shaft, gears, toolholders and tools), by pulsating oil pressure from gear pumps and by cutting forces from milling cutters—to a high feedrate or to depth-of-cut (see Figure 2).

Finally self-excited vibration, or chatter, is obtained by the feedback process of regeneration of waviness on the cut surface. It involves a steady input of energy modulated into vibration. It arises in all machining operations if there is enough gain in the feedback process and if the chip width exceeds a limit value dependent upon the dynamics of the machine. When it occurs in machining, it is inevitably violent, destructive and difficult to eliminate, as the speeds and power increase. Chatter becomes the main limitation of the usable metal removal rate (MRR) (see Figure 3).

Frequencies: The Key to Chatter Elimination

Example: A 3/4" carbide cutter x 1" length of cut, three tooth, cutter (stackup) assembly natural frequency of 1,500 Hz, spindle speed of 15,000 rpm.

With self-excited vibration, chatter will occur with this stackup at a frequency close to the natural frequency of the stackup in the assembly in the machine tool. For example, if you have a stackup natural frequency of 1,500 Hz and the operation is chattering, then the frequency of the vibration you will feel or hear when cutting will be around 1,500 Hz.

Forced vibration of this operation will occur at a frequency of spindle speed, such as in the case of unbalance or too high a feedrate. rpm/60 x number of teeth will give us frequency in which forced vibration will occur. A stackup with three teeth will be running at 15,000 rpm, the frequency of the vibration you will feel or hear when cutting will be 15,000 / 60 x 3 = 750 Hz.

This information provides the key elements to determine when you are having a problem in machining and what it is, so it can be eliminated. As you will notice, using these stackup and machine parameters that chatter and forced vibration frequencies that might occur are distinctly different frequencies, which will make it easier to determine the cause. Simply put, from the example—chatter will occur at a frequency of around 1,500 Hz and forced vibration will occur at a frequency of around 750 Hz.

Generally it is very difficult, if not impossible, to determine what frequency the noise is occurring at without using proper equipment. Fortunately, there are some conditions you might look for to help determine the condition. Chatter is more of a piercing chirp because it is usually a higher frequency—the less mass, the higher the frequency. While forced vibration is more of a shaking condition due to a lower frequency—the more the mass, the lower the frequency, which is coming from components of the machine tool structure.

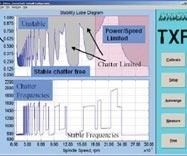

If you know the natural frequency of the stackup assembly, then you can suggest the best rpm and depth-of-cut of the machining operation so chatter does not occur. This is the quickest, most cost effective way to eliminate chatter. Many companies spend countless hours making test cuts, resulting in only estimations at what true parameters can be used to fully maximize a machining operation. It is very cost ineffective as compared to doing an Impact Test. An Impact Test provides you with detailed information in a matter of minutes, producing a Frequency Response Function and Stability Lobe Diagram of the stackup giving the power, spindle speed, material being machined and flexibility readings to intelligently suggest the best rpm and depth-of-cut.

To effectively predict at which rpm to run a stackup, one needs to know the natural frequency of that stackup. In the aforementioned case, it is natural frequency x 60/number of teeth or 1,500 x 60/3 = 30,000 rpm. This would be the highest rpm, 1x multiplier, which this stackup would want to run—giving the highest depth-of-cut. If this rpm cannot be reached, divide it by two to give the 2x multiplier to run this stackup at = 15,000 rpm; however, depth-of-cut and feedrate also will suffer. The higher the multiplier used, the lower the depth-of-cut and feedrate. Stay with the highest multiplier to maximize the operation.

If one is taking test cuts without knowing the natural frequency of the stackup, then it is most likely he or she does not know which multiplier of rpm is reached if the cut can be stabilized. If one so happens to hit the 3x rpm, he or she will not know if 2x or 1x rpm can be reached to maximize the operation. In the process, a lot of time will be spent guessing for an rpm when they could easily identify the highest rpm with and Impact Test and document it in a Dynamic Database. If the same stackup parameters (Dynamic Database Input) are used in the same machine later down the road, it will still have the same dynamics and run as it did before. Chances are that a stackup will run in another machine of the same exact model due to machine dynamic tolerances when machine tools are built from the factory. Therefore, one only needs to do one Impact Test of a stackup for that machine model to collect proper rpm and depth-of-cut.

Chatter Myths

The following information will help you to distinguish myth from fact. Author comments are italicized and expert example comments provided by MLI are proceeded by "MLI."

- Unbalance—such as toolholder unbalance—causes chatter.

We now understand from information in this article that unbalance and chatter are occurring at different frequencies. Unbalance is forced vibration while chatter is self-excited. Unbalance does not cause chatter. If you measure the finish it will tell you the frequency, which in turn will tell you if the problem is unbalance or chatter.

MLI—Forced vibrations are produced by a periodic force acting on the system. A harmonic force has a single frequency f and it excites vibration x with exactly the same frequency. For instance, if you find that waviness on the ground surface was caused by a frequency of 29.2 Hz, measured as peripheral speed v of the workpiece divided by the wavelength w of the marks, then f (Hz) = v (mm/sec)/ w (mm). You will readily know that it is caused by mechanical unbalance of the rotor of a four pole induction type motor running at nominal 1,800 rpm (30/sec) with a slip (1,752 rpm), perhaps one driving the grinding wheel spindle over a belt transmission. - What is chatter and how would you define it?

Bad surface finish; usually a result of too much spindle speed.

Yes, in this instance chatter will create a bad finish, but it is probably not a result of too much spindle speed. The 1x multiplier spindle speed needs to be known to determine this and if the machine tool can reach that rpm. To lower spindle speed, many times simply stabilizes the cut due to process dampening.

Chatter is when the tool or material bounces or resonates while cutting. It's caused by a lack of chip load in most cases. It leaves bad finishes, beats up the cutter and sounds nasty. It can usually be eliminated by shorter tools, heavier chip loads, higher rpms and sturdier stock/setup.

Most of this comment is correct except for chatter being caused by lack of chip load. The cutter, holder, spindle or machine self-exciting causes chatter, resulting in very high chip thickness variations as each tooth of the cutter passes during a cut—also referred to as regeneration of waviness. It continues to grow until the chip thickness is exceeded and the cutter jumps out of the cut. If the chip load is light and the cutter is chattering, it will exceed the chip load more quickly. The best thing to do is to change rpm or simply know the proper rpm by calculation of the natural frequency method. Continue to use cutter manufacture chip loads and sfm recommendations for any rpm. - Chatter is usually caused by the milling machine and not the actual part.

Not true. Usually the setup, speeds/feeds and tooling are to blame. Most chatter can be eliminated with heavier chip loads coupled with lower sfm, regardless of what machine it's on. Don't be shocked to notice that on finished cuts, you could end up at 1,500 rpm at 15 ipm with 1/2" EM.

Applying heavier chip loads would not be the best thing to try to eliminate chatter; rpm should be the first thing examined. Lowering sfm is not a good way to maximize the operation. This is a tactic that has been used for many years and although it does work, it is undesirable—called process dampening. If you are working on one part it may be useful, but if you are running production it is too costly. Process dampening keeps the cutter in the cut for a longer period of time to keep it from chattering resulting in very low MRR while putting high stress upon the machine tool and cutter assemblies. - What kind of feed would you use with a 1/4-ball mill four-flute at 6,000 rpm spindle speed in 7050 aluminum T4? You may have to slow down the spindle to maintain the minimum finish feedrate (ipr - not ipt) to get a good finish with no chatter.

A 1/4-ball end mill is a small tool and holder assembly, which in turn, has a low mass, so it will have a higher natural frequency reading than a one-inch ball end mill assembly. Therefore, it is likely that this 1/4-ball end mill assembly in this machine will want to run much faster of an rpm to stay out of chatter than this machine can give. Also, 6,000 rpm might be a very bad rpm, but one would need to have a FRF (Frequency Response Function) to determine the natural frequency and lobe chart of the cutter to find this out (See Figure 4). If the natural frequency of the cutter assembly is just 1,500 Hz, which is a conservative estimate of frequency, then the 1x multiplier rpm of this cutter assembly would be: 1,500 x 60 / 4 = 22,500 rpm. This would be the best possible rpm to provide highest depth-of-cut and feedrate. 2x = 11,250 rpm, 3x = 7,500 rpm, 4x = 5,625 rpm. Remember that with each multiplier the chances of improvement diminish to maximize MRR.

Chatter control is not simply limited to machining of aluminum, it all has to do with the material's sfm and knowing the maximum rpm to stay out of chatter with that material, especially with ball end mills and long reach cutters. Clearance angles of cutters alo can cause premature chatter conditions; too much clearance on the periphery of a cutter will cause chatter and not enough on the end of a ball nose will cause lower depth-of-cut.

These are just a few of the myths about chatter, but armed with the information in this article you should be able to determine a myth from a fact. There are other factors about chatter that should be considered—such as equipment used to take readings of cutter assemblies that provide stability lobes, FRF, database management of readings—but at this point, you have a good foundation as to what chatter is and how to eliminate it.

Related Content

Hybrid Milling/Drilling Machine Reduces Total Mold Machining Time

MSI Mold Builders now squares, plus drills and taps eye-bolt holes on 50% of its tools in a single setup using a five-axis milling/drilling center with a universal spindle.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreHow to Produce More Accurate Molds and Reduce Rework

Patented micro-milling process for manufacturing steel plate flat and parallel helps mold builders shorten mold build times and increase accuracy.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreRead Next

High-Speed Mill Keeps Tight Tolerances, Increases Efficiencies

Busy moldmaker turns to HSM to boost productivity and remain competitive in both the domestic and foreign arenas—and realizes time savings of up to 60 percent.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More