How to Become a Better-Informed Mold Purchaser

Six questions every purchasing manager must answer to improve his or her buying skills and create more value for the company.

Molds are considered a commodity. A statement all too familiar to most of us, as it has become the general attitude within the injection molding industry that hires employees who do not fully understand the complexity of manufacturing an injection mold. I want to share a perspective that may help facilitate the buying and selling of molds, as I have experience working on both sides of the process, selling injection molds to buyers and buying injection molds as a purchasing manager.

Six Questions

Mold buyers have a unique job in which they can either set up a manufacturing process for success or cause the company to lose profitability. A lack of understanding exactly what they are purchasing hurts productivity. Purchasing only on price and delivery is not the proper matrix for evaluating a mold. Putting part size, the number of slide actions, steel type and manufacturing location into a spreadsheet does not calculate the best mold price. The calculation is much more complex than that.

Here are six questions every purchasing manager should answer to improve his or her buying skills and create more value for the company.

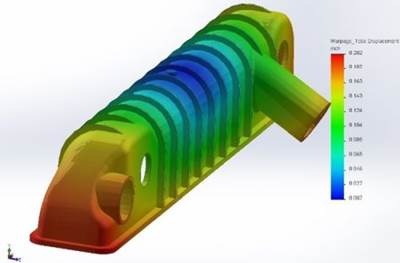

- What is the function of an injection mold? A cooling fixture that forms a part out of heated plastic. The faster a mold can dissipate the heat of the melted plastic, the faster the cycle time will be. What does your company sell? Press time. My goal is to find suppliers who will engineer melt delivery systems and cooling systems to reduce cycle time and scrap. There are times that the mold cost will increase, but through some simple justification tools, cycle time and scrap reduction can pay for the increased cost. Other items like the size of the mold, number of slide actions, type of steel and location of the tool build all affect the overall cost and performance of a mold. I recommend working with your tool engineers or suppliers to gain a better understanding of what you are purchasing and how to justify the costs. Sometimes paying more for the mold will increase productivity in production and increase overall company profitability.

- How many suppliers do you utilize? I have reduced my supplier base to increase my buying power. I will source a package of tools to the supplier's strengths to reduce my cost. When I started as a purchasing manager at EG Industries, a tier one automotive supplier and medical molder, the company had more than 40 approved mold suppliers. I reduced this to 20 mold suppliers. I approved each supplier based on what type of molds they were best at building and by location. Sourcing into the supplier's sweet spot allows me to negotiate the best cost, quality and delivery balance. My first program at EGI was a $5 million tooling program. With buying the right mold and sourcing packages of tools, I was able to reduce my tooling budget by $450k or 11%.

- Do you pay suppliers on time? Another way to reduce cost is by having a reputation for paying promptly. Not paying on-time increases the risk the supplier has in collecting its money and the need to use bank financing. I recommend talking to your suppliers and negotiating a cost down for early or prompt payment. I would expect a cost reduction of 2-3%.

- Does your company need extended payment terms? Payment terms are tough because we need to increase cash flow and company EBITDA by extending terms. However, there are other means to accomplish the same objective. Some shops are large and financially stable enough to offer extended payment terms. Canadian mold shops have an advantage over USA shops because they utilize Export Development Canada to obtain government insurance on receivables. This reduces banking risk and allows the shop to get better interest rates and larger lines of credit. Another means to get extended terms is factoring the receivable to a bank that understands the automotive tooling process. By using this process, I was able to reduce the initial tool cost, which paid for the cost to factor the receivables. This was a win-win situation for my company and its suppliers. I encourage you to work with your finance team and suppliers to find a solution that helps you meet your objectives.

- Is your supplier healthy and going to be around to meet your needs? One of the worst things that could happen during a mold build is a supplier going out of business. The business end of mold manufacturing is tough. Banks dislike mold builders because they are hunters and gathers that don’t know from where the next job will come. I look for financially healthy suppliers who maintain a culture that empowers employees, invest in the future through equipment and apprenticeship programs and have a succession plan in place. These factors help determine if a business is being properly managed or if the business is managing them, which is never a good idea. Many mold builders are privately held, so it takes some work to find out these items, which is the reason I recommend taking the time to get to know the owners and senior leadership.

- How do you know you chose the right supplier? Many factors impact the decision to award business. I use a Pugh matrix to create a selection method that not only evaluates cost, quality and delivery, but the supplier’s experience level along with the type of business, company culture, financial health and ability to meet my objectives. This selection process is a scientific method that allows me to be more objective about my decision-making process and provides a quantifiable reason for choosing one supplier over another.

If you follow some of the above recommendations, I am sure that you will be able to find creative ways to reduce your mold costs and increase the strength of your supplier relationships.

Related Content

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreHow to Correctly Size a Hydraulic Cylinder

This week Randy shares steps for correctly sizing a hydraulic cylinder on a mold.

Read MoreLine Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

Read MoreRead Next

Are American Purchasing Agents Hurting American Manufacturing?

Bob Elwell owns his own engineering firm and is excited to share what he has learned throughout his career when it comes to tooling challenges. Specifically, purchasing.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More