Are American Purchasing Agents Hurting American Manufacturing?

Bob Elwell owns his own engineering firm and is excited to share what he has learned throughout his career when it comes to tooling challenges. Specifically, purchasing.

Bob Elwell has always been intrigued by the ways companies operate, specify, design and procure plastic product designs, prototypes, production molds and molded plastic parts. His fascination began more than 30 years ago when he entered the plastics product design, mold building and molding industry. He started in mold design and manufacturing, and then moved onto product design, tooling management and purchasing. Today, Bob owns his own engineering firm, Procad Technologies, and is excited to share what he has learned throughout his career when it comes to challenges of tooling. Specifically, purchasing.

While the technical side of engineering and manufacturing has changed and improved, the business side has had to adapt to domestic and international competitive pressures. Purchasing departments have been tasked with making companies more profitable by lowering the costs of purchased goods. This entails moving manufacturing to different vendors, including those offshore. Over the last several decades, an increase in offshore manufacturing has dramatically changed the injection mold market. These offshore vendors have been quite creative in how they bring U.S. companies in to buy products. Here, I will focus on purchasing departments and the decisions they make here in the U.S.

As companies were forced to find ways to be more profitable, training lessened, efficiency was reduced, work shifted offshore and jobs were lost. It became easier to outsource our way to profitability while forcing the risk and expense to the vendors. While this may look good on paper, it does not always work out that way.

For example, engineering was now tasked with designing a low-cost quality product that could be manufactured, but ran short on time and out of budget. The reduction or total avoidance of prototyping and computer simulation became commonplace, and product or manufacturing flaws remained in designs. Purchasing, on the other hand, was charged with outsourcing these designs to “qualified” low-cost vendors. Company owners and management created financial incentives for the purchasing management to save money while outsourcing. This created internal departmental politics and a blame system typically aimed at engineering and manufacturing.

Some purchasing managers seemed to focus more on their own bonus programs rather than the assigned projects, and engineering scrambled to stay on schedule and on budget while supporting those designs with the new vendors. Oftentimes, engineering either had no input on vendor selection or, if they raised concerns that the vendor was not able to manufacture according to specifications, the objection was likely ignored. As the project moved along, problems would arise due to miscommunication, material specifications, processing requirements, molded part tolerances, testing requirements and schedules.

One old project outsourced to China that I was assigned to fix was more than two years late and never produced a product that would pass any impact tests. The amount of extra time and money that was spent trying to get that product assembly to pass was nearly 100-percent over budget. The customer was extremely upset to the point where they just stopped calling to complain. After reviewing the project, we focused on fixing the problem using best practices in materials, mold design and processing. Three tooling revisions and six weeks later, we could get the product to pass all tests.

It is for these reasons that companies have implemented cross-functional team approaches and multiple approval processes through which each discipline is represented. The stage gate process is an example of a procedure to review, identify and fix problems, and then approve them before they move on to the next milestone. While these approval processes help management and employees from different departments work together better, they still do not address individual skills, training and experience. As technology progresses, the gap between each department and discipline gets wider and wider. Communication remains difficult and people resort to interpretation, personal preference and politics to fill in areas of disagreement. The more people you involve, usually the more complex the process gets.

I am sure we have all seen molds and molded parts that violate best practices in product design, mold design, materials or process. In many cases, the violations are a combination of two or more of these areas. For example, the product designer, mold designer or processor not communicating to review potential problems. This only leads to product failure, broken molds, long cycle times and lost money.

All of this was the motivation I needed to launch a company focused on the interface between product design, tool design and manufacturing. The company specializes in optimizing the product design for performance, but also focuses on wall thickness, gate location, runner design, material flow and properties, using computer-simulated mold-filling analysis combined with stress, thermal and dynamic analysis.

More from Bob here:

- http://procad-tech.com/news-articles/

- http://procad-tech.com/product-design/

- http://procad-tech.com/mold-filling-analysis/

- http://procad-tech.com/analysis/

Related Content

United Grinding Precision Summit to Feature 16 Machines, Technical Sessions

The first ever Precision Summit is happening in Miamisburg, Ohio on May 24-25, 2023.

Read MoreFour Industry 4.0 Tech Adoption Insights from Indiana Plastics Manufacturers

As more plastics manufacturers step into the Fourth Industrial Revolution, insights have emerged about how best to approach the digital transformation journey.

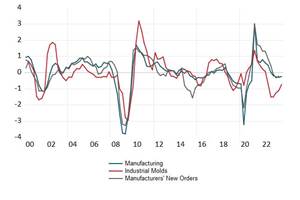

Read MoreNavigating Economic Resilience and Consumer Trends

Consumer behavior provides mold builders insight into the evolving market dynamics of goods and services that helps strategic planning.

Read MoreUnited Grinding Announces Support for the Reshoring Initiative

According to the Reshoring Initiative, the rate of reshoring job announcements has grown from 10,000 per year in 2010 to 350,000 per year in 2022.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More