Greater Accuracy and Productivity Via Surface Finishing and Cleaning

Choosing the optimum type of flexible hone or brush can be highly effective in improving the accuracy of mold assembly or enhancing injection molding productivity.

The use of relatively inexpensive yet specialized grit brushes or honing tools can be highly effective in improving the accuracy of mold assembly or enhancing injection molding productivity through more efficient cleanup of metal surfaces.

For example, the precision guide pin bushings used to ensure proper mold alignment may benefit from the use of a ball-style hone or abrasive brush to achieve tight tolerances by polishing the bushing I.D. or performing other surface finishing operations that improve alignment and extend overall service life.

The use of a flexible, ball-style hone with the appropriate grit material and grit count can enable users to polish virtually any size bushing that is used for mold alignment.

The right ball-style hone will operate with globules or balls of abrasive grit permanently attached to a flexible filament that extend from a central shaft. The tool should be available in miniature sizes as small as 4 millimeters (0.156 in.).

In operation, when using a drill motor or other rotating device, a ball-style hone can produce a controlled surface condition unobtainable by any other method. The tool is self-centering, self-aligning to the bore and self-compensating for wear.

There are many companies in the injection molding business that are using ball-style hones to clean their extruder barrels when they change colors or when the barrels require routine maintenance.

This tool enables them to do that quickly and economically.

Another typical application is the cleaning of nozzle orifices. Even orifices milled with EDM machines often have surfaces that are too rough and therefore can benefit from polishing that can easily be accomplished with the right industrial brushes or flexible hones.

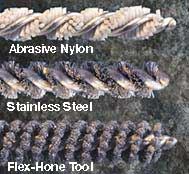

Brushes and ball-style hones are available in a wide range of sizes with a broad selection of filaments and grits. There are several types of miniature brushes available today that vary not just in size, but also in filament type. Carbon steel, stainless steel, brass, nylon and abrasive filled nylon are commonly used. Abrasive filled nylon can contain silicon carbide, aluminum oxide or diamond abrasive.

These tools are also used for finishing cavities in the mold themselves. In cases where you need a very smooth surface finish the right brush or ball-style hone can ensure that those areas are highly polished with a minimum of effort and expense.

For those who have concerns about choosing the optimum type of flexible hone or brush for their application, such as filament and grit materials, look for suppliers who offer support through the engineering department and who run tests simulating application conditions within a surface-finishing laboratory.

Related Content

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

Questions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.