Find the Right Product Innovations for Your Mold Shop

Take a look at these latest product announcements targeting the moldmaking industry from hot runner nozzles and end mills to 3D printing innovations and mold cooling systems.

MoldMaking Technology strives to keep its readers up to date on the most relevant innovations that are being supplied to the mold and die industry. Each day, we share a new or improved technology, or a well established company service, and our monthly technology roundups seek to gather this information into an easy-to-digest format so that you don’t miss it.

What follows are some digital-only products showcased for the month of October. Others — which made an appearance in the October print/digital issue — were compiled in these “Moldmaking-Related Technology Highlights.” Access the complete product post through each linked title. If you’re interested in more content like this, we encourage you to take a look at the other roundups published this year.

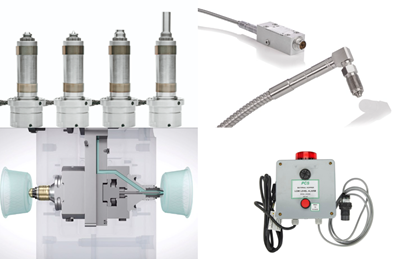

Water Temperature Control is Upgraded and Integrated Into Machine Control

Engel showcases its new eco-flomo temperature control system for continuous monitoring of all injection mold cooling and temperature control circuits. Integrated into the Engel injection molding machine’s CC300 control unit, eco-flomo uses Engel’s iQ flow control software platform to detect irregularities and boost process stability and reliability.

Hot Runner Nozzle is Enhanced With Interchangeable Needle Gate Chamber

Hasco is expanding the Vario Shot nozzle program series from its Hasco Hot Runner Business Unit with a replaceable Vario Shot Xgate needle valve prechamber. This adds to the company’s extension in 2021, which also optimized the technology’s cable outlet placement.

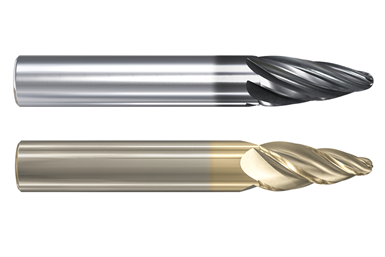

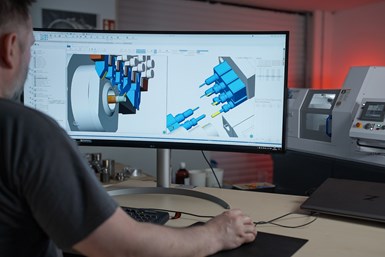

CAM Software Solutions Streamline CNC Machining

SolidCAM highlights CAM solutions for faster, more efficient machining — seamlessly integrated and associative in Solidworks, Solid Edge and Autodesk Inventor.

SolidCAM’s iMachining is said to save 70% or more in CNC machining time, increase tool life 5X or more and provide users with optimal automatic feeds and speeds with the patented Technology Wizard.

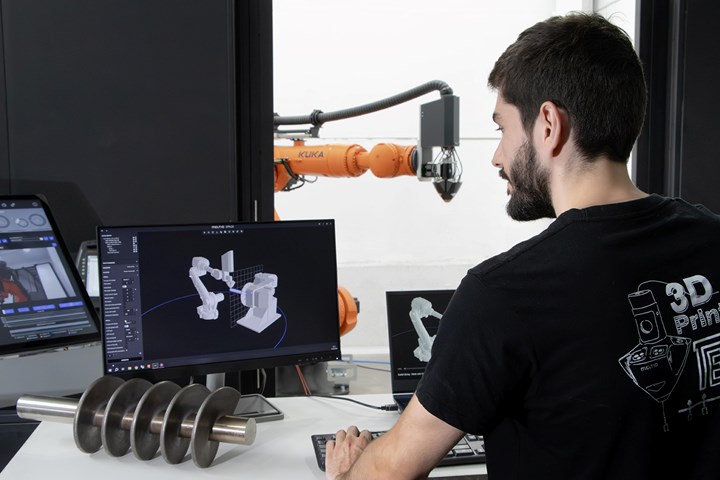

Robotic Metal 3D Printer Automates, Augments AM, Repair and Cladding

Meltio launches the Meltio Robot Cell, a turnkey plug-and-ply robotic arm solution for safer, more reliable and highly accurate metal additive manufacturing (AM) of components autonomously, as well as part repair or a feature addition, attributes that have been seen to produce long-lasting multi-material molds in hybrid AM applications. The entire process is controlled with the company’s Meltio Space slicing software.

Read Next

Quality Control Technologies Geared for Injection Molds

These latest technology solutions, from noncontact gages to test probes and automated inspection systems, aim to minimize production risks and ensure optimal quality control practices for moldmaking.

Read MoreProduct Innovations Pushing the Mold

Another tech roundup is here to provide an overview of technologies and services on the market for moldmakers. Featured in this roundup are cutting tools, mold components and more.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More