Efficient Machining of Micro EDM Electrodes

To achieve efficiency and quality in machining micro EDM electrodes, consider a machine dedicated to this process.

Much has been written about the technology and process required to achieve efficiency and quality in machining small EDM electrodes. Yet, the proven methodology is not always employed by mold manufacturers due to the perceived cost of a graphite machining center designed to withstand this abrasive process and also produce intricate micro electrodes.

Indeed, the upfront cost of a machining center—featuring dust protection—is significantly more than a conventional metal-cutting CNC. That is why many mold manufacturers would rather make an inexpensive milling machine do double-duty: machining metal and producing graphite electrodes in rotation. There are a couple of flaws in this approach.

First, this type of machine may take a beating machining graphite if it lacks the appropriate dust protection and it may not have the tight tolerance required for repositioning and redressing electrodes. The bottom line is that achieving efficiency in machining micro EDM electrodes calls for a machine dedicated to this process and designed for it.

Machine Criteria

Such a machine should provide dust protection and the high-spindle speed required for intricate machining with micro tools. For dust protection, look for a machine that employs covered linear guides and ball screws with positive air flow to ensure that no abrasive or harmful materials can get into the motion mechanics of the machine. Also consider an automatic greasing system that forces any debris out of the machine’s working parts.

In addition, a sealed housing for all motion control electronics and motors that will protect against contamination of the machine control system. The spindle should be pressurized to prevent any dust from entering the bearings. Plus the machine should have dust extraction.

For example, a graphite vortex unit surrounding the spindle and workpiece that features an industrial brush head and a spiral air flow extraction chamber—limiting the travel of airborne dust and working in concert with an external dust collection system to remove debris from the machining environment—is an option.

Many manufacturers ponder the importance of the CNC control and its processing power. It is true that a high-end CNC control will yield optimum results on large complex molds. But, when milling smaller electrodes with micro-tools, the advantage of a high-performance control, while still apparent, is not as substantial.

Typical mill speeds with micro-tools are 50, 100 or 150 ipm. Therefore, standard industrial PC controls are acceptable for most applications, and controls based in a Windows environment offer more flexibility and ease of use due to the familiar format. Aside from the machine itself, the micro tooling used should feature diamond or specialty coatings designed specifically for abrasive materials.

Consider a light-weight machine: While both conventional VMCs and specialty high-speed mills excel at milling graphite molds, consider the overall ROI and benefits of smaller machines to mill intricate electrodes.

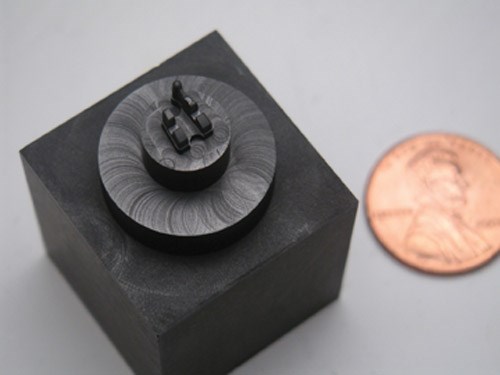

Many graphite parts used in the mold industry are small and intricate. Fuel cells that use graphite components have detailed features milled into them. Compact and light-weight machines are ideal for these micro-milling applications. Plus, there are many benefits that occur as a byproduct of the machine being light-weight.

The first benefit is the most obvious, as manufacturing floor space is becoming a premium, a smaller footprint means that two or even three machines can fit in the space of one larger VMC. As a result, the manufacturer can double or triple throughput without incurring the cost of additional space.

Perhaps more importantly, is the long-term savings that can be achieved as a result of the low-power requirement of some light-weight machines. Smaller motors and drives require fewer amps—drawing a meager 5 to 6 amps with 208 single phase power—saving money on electricity.

Also, light-weight machines use light-weight components, so the replacement cost is less. Often these small replacement parts can be shipped inexpensively and installed by maintenance staff rather than requiring an onsite visit from a service engineer. In many cases the turn-around for the replacement is quicker and this maximizes uptime.

Finally, if a machine needs to be moved, smaller machines are easier to handle and usually a fork lift or even a pallet cart will do—eliminating the need for and cost of riggers and factory service personnel.

Keep in mind, light-weight should not sacrifice rigidity and durability. Some light-weight machines are available with cast steel construction and solid granite or concrete polymer machining tables. This stiff mechanical construction is of paramount importance for machining intricate graphite EDM electrodes with superior surface finishes. Also, make sure to examine the machine’s travel capabilities as ample Z travel is required to accommodate typical graphite fixturing systems.

High RPMs: The wonderful thing about graphite is that it cuts easily and unlike metals such as steel it won’t anneal or get heat treated at high RPMs—so, high feeds and speeds can be employed to reduce cycle times.

High-RPM spindles assist in proper evacuation of debris from the cutting tool and are the most effective means of using the fragile micro tooling required to machine thin walls and intricate detail on small EDM electrodes.

The spindle should be kept at a constant temperature with a chiller. This will help in the overall accuracy of the machine. A low-vibration spindle that uses specially-balanced toolholders is also desirable when using small tools. This will aid in achieving the best surface finish possible.

Summary

In machining intricate graphite EDM electrodes, the word efficiency means many things—getting a good quality part, reducing cycle times, minimizing operational costs and protecting the capital investment by prolonging the lifecycle of the milling machine.

So, achieving real efficiency means selecting a machine designed for this process. Dust protection, light-weight construction, high-spindle speed, rigidity and low power consumption are the key ingredients to success or true efficiency in this application.

Related Content

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More