Don't Get Burned ... with the Wrong Hot Runner System

The type of hot runner system you put in your mold will impact performance as much as the engine in your car determines how you’ll drive and how many headaches you’ll have down the road. Here are five questions to ask that may help ease the decision-making process.

Not unlike a car, the first mistake people make when it’s time to order a new hot runner is that they repeatedly return to the same make or dealer, instead of investigating other available options. We all do it. It’s human nature. We go with what we know. It seems easy and safe to call the same person with whom you’ve always worked and order the same system as before.

The only valid reason for repeating this purchasing behavior is that the last system was perfect in price and performance. Although many times this is the scenario, what happens when you’re not satisfied? Do you go back for more? If so, why? Maybe it’s time to analyze your hot runner solution decision-making process.

This is according to MHS - Mold Hotrunner Solutions Director of Business Development Jorg Schmidt. Here he shares some rules to live by when it comes to hot runner system selection:

It’s important to involve a number of hot runner suppliers when launching a project, and not just for keeping the pricing competitive. Involving a variety of suppliers enables you to hear a variety of concepts, proposals and quotes, which can save money and time. However, be sure to compare apples to apples when evaluating hot runner solution options. There are many methods for cutting corners, which can significantly impact the performance of the hot runner and the overall cost of ownership that may not always show up on paper. A good supplier will add value to the mold, offer new ideas and educate your team.

Modern moldmaknig relies on technically-competent, passionate, hands-on people, but not all purchasing departments are equipped to determine the true, long-term cost of a system based on the quotations and the spreadsheets in front of them, especially in larger corporations. It is important for those evaluating hot runner systems to determine what sets solutions apart, possess practical experience with molds, spend time in production, consider engineering, analysis, materials, surface treatment, precision machining, assembly, quality control, sensors and controllers, extra heaters, R&D, etc. Establishing a company culture that provides purchasing with the proper skills and know-how is essential when it comes to investing in the right hot runner solution.

Today’s hot runner systems range from extremely low-cost, off-the-shelf solutions to customizable, precision, high-quality manifolds, making the choice of the appropriate solution for the application-at-hand a bit of challenge. However, here are five questions to ask that may help ease the decision-making process.

1. How can I improve the plastic part design with optimization?

Hot runner supplier support is key when discussing the plastic part design, which should occur long before gates and nozzles are selected, drawings are exchanged, steel is cut or any plastic is flowing. First of all, a true hot runner partner will provide a proper analysis of your project. This includes mold flow simulations, cool, warp, and fill analyses, as well as a thorough review of other important rheological considerations. The resulting report is extremely valuable because it should validate your mold design or propose specific actions to optimize the gates and the injection of your plastic part (faster, stronger, lighter...). Your hot runner supplier should also provide concrete examples of successful projects to demonstrate their experience with relevant projects. It is very important to have direct access to a competent team of experts. Don't be left on your own. Make sure you always have an experienced engineer or service technician you can call up at anytime. Someone helpful who can have an in-depth discussion with you about your project, not an operator with a troubleshooting spreadsheet, or a call center, or a sales rep, or a DYI online manual.

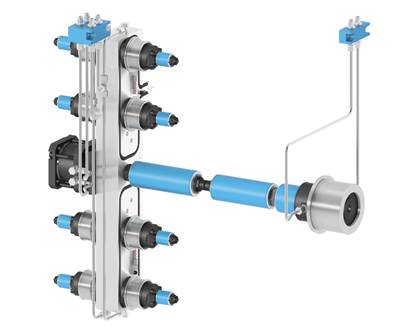

2. What is possible with new hot runner technology?

Hot runners have evolved a great deal over the last decade, and so should the solutions hot runner suppliers offer. It is in your best interest to ask about new technology offerings. There’s no risk in listening to new ideas. While a certain degree of standardization is a good thing, too much prevent achieving better results. Many times this becomes a shop mindset challenge.

For example, the maintenance department feels more comfortable doing things the old way or people are afraid to rock the boat or lose their job. If this sounds like you, it’s time to start encouraging innovation, flexibility and open-mindedness. Now is not the time to be afraid to think outside the box. It is time to investigate new ways of doing things. Check out the latest technology, search online, read reputable publications, visit trade shows, attend conferences and talk to experts. These are the only ways to truly discover what really works and what doesn’t.

3. How do I measure hot runner performance?

Hot runner performance can and should be measured using cycle times, output, dollars and cents, part quality, uptime, downtime, after-sales costs and level of stress.

4. How user-friendly is my hot runner?

This can be answered simply by determining how often you curse the design or functionality of the hot runner system. The truth is, things can go wrong inside complex molding cells. Ask yourself honestly whether it the hot runner is the root cause, if you are satisfied with the manner in which issues are resolved by your technical support team, and if the frequency at which downtime occurs is acceptable to you. If you feel there is room for improvement, t may be time to try a new system - not all hot runners are created equal. Ask for product demonstrations and some free training. Another good resource are material suppliers, as many issues that are thought to be mechanical are actually the result of unknown material properties.

5. What’s the true cost of my hot runner?

First, think long term, as most molds run for years or decades. Evaluate the time and money spent on maintenance, spare parts and service. Is the service same or next day? Are you paying too much? Ordering spare parts or getting effective support should never be painful. Demand more from you suppliers.

Check out Schmidt’s article on internal valve gates here.

Related Content

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreRead Next

Benefits of the Internal Valve Gate

Not everyone is familiar with how internal valve gate nozzles work and when to use them.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More