Benefits of the Internal Valve Gate

Not everyone is familiar with how internal valve gate nozzles work and when to use them.

Internal valve gate nozzles have changed the rules of valve gating technology and opened the door to new possibilities, from high cavitation to single-drop hot runner systems. However, many mold builders and molders are not familiar with this nozzle option. Here, I will review what makes this technology clean, compact and durable for all applications.

Features and Functions

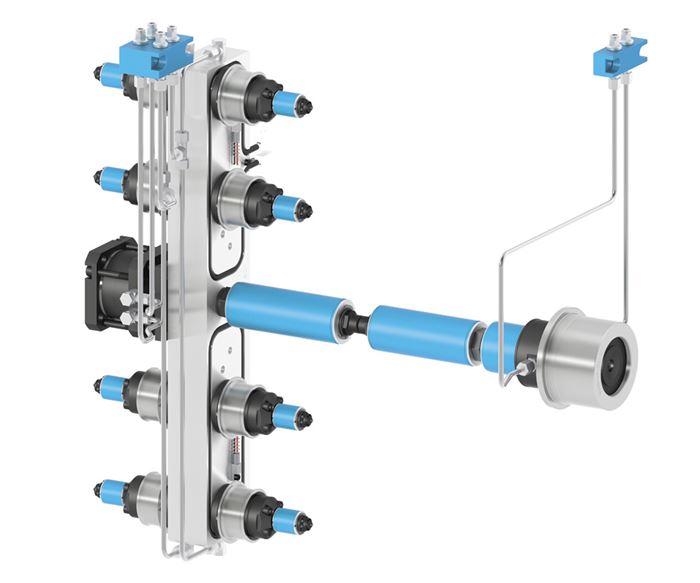

Internal valve gate hot runner nozzles are defined by their durable internal or integrated piston. Every feature of the actuator is located directly inside the nozzle body so that everything takes place on the nozzle side of the manifold in a single, compact unit (Figure 1). The valve pin mechanically opens and closes the gate at the nozzle tip with timing down to the millisecond and accuracy down to 0.0001 of an inch (2 microns). An all-metal pneumatic piston drives this process. The piston produces more force and a more powerful shutoff stroke than traditional pneumatic actuators that have O-ring seals or electric motors.

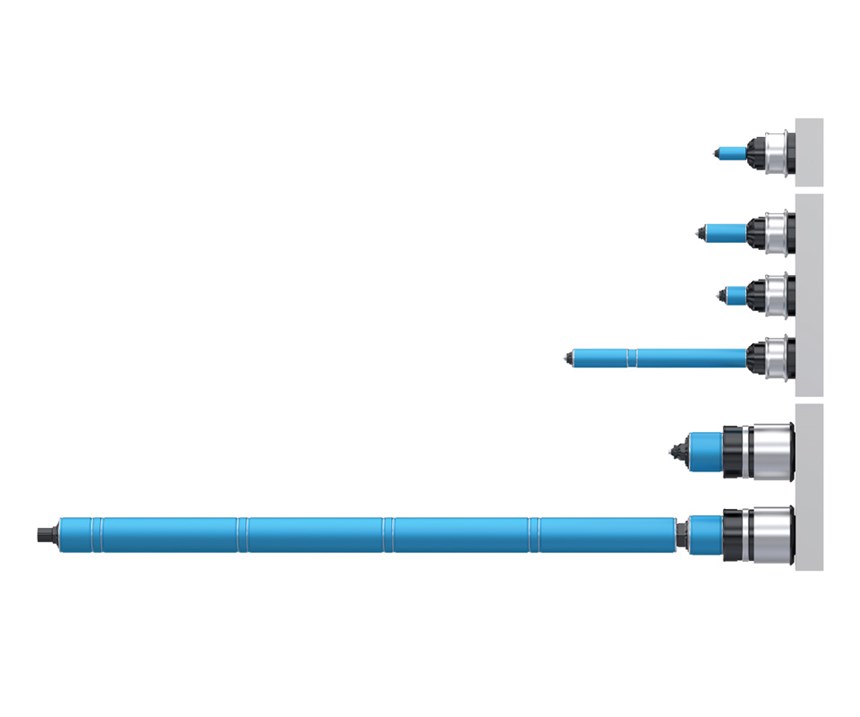

One common misconception about internal valve gates is that they are only for processing high-temperature materials. While they are ideal for high-temperature applications, virtually all valve gate projects operating at any temperature can benefit from the reliability and user-friendly design of an internal valve gate nozzle. However, part size matters. Internal valve gate nozzles are not suitable for micro-sized plastic parts or tight gate spacing under 63.5 mm/2.5 inches.

When it comes to maintenance, lubricating the piston is not necessary. There are no soft seals, only specially-treated metal seals that do not wear or break down, which reduces machine downtime for maintenance and repair. This also makes internal valve gate nozzles a good fit for cleanroom environments.

Under normal operating conditions, the piston should remain untouched inside the nozzle body for the life of the mold. For any quick nozzle maintenance that may occur outside of the piston, like replacing a nozzle heater or thermocouple, all components are fully accessible from the cavity side of the mold while the mold stays inside the machine. The nozzles are seated (Figure 2), so there are no components inside the manifold—a feature of some older actuators. This gives the mold designer the option of running air supply channels directly inside the hot runner manifold, which further simplifies design and assembly.

Mold cooling is another important issue. The use of internal valve gate nozzles eliminates the need to incorporate cooling lines into the hot runner design or to incorporate an external actuator outside of the nozzle. This saves a lot of space and energy costs over the life of the mold. It reduces the added expense that is associated with the hardware and assembly of cooling lines made from copper, steel or flexible tubing. Additionally, coolant causes common maintenance issues that cooling-free internal valve gate nozzles avoid, like leaks and blockages due to human error, poor water quality and corrosion.

Benefits and Applications

With everything housed inside a self-contained, compact unit, mold designers can create smaller molds that cost less to produce and operate in smaller injection molding machines. Designers can also place gates into tight spaces.

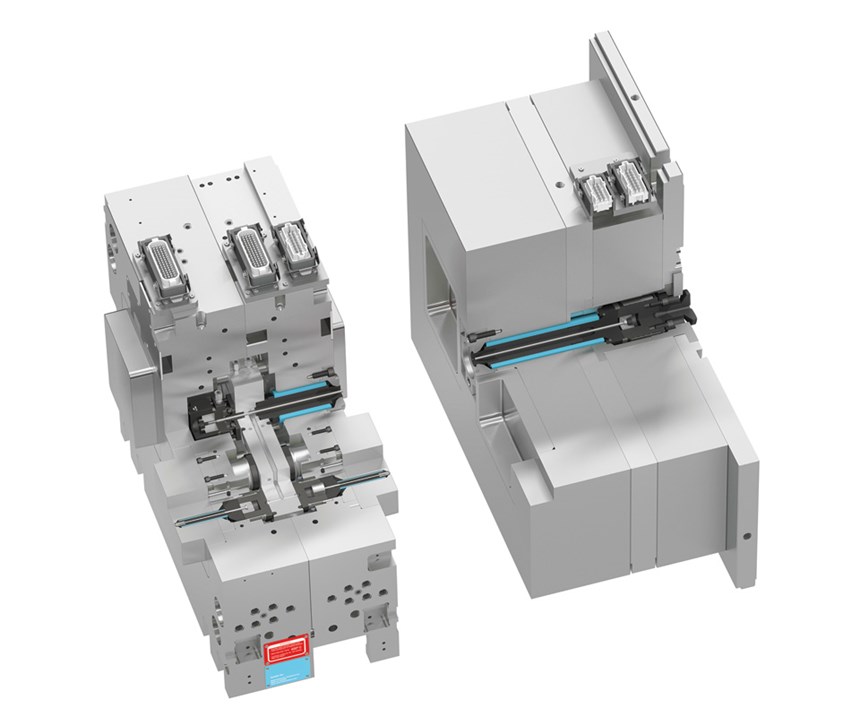

A common application for internal valve gate nozzles, which eliminate traditional rear-mounted or manifold-integrated actuators, are stack molds with two parting lines where the nozzles are arranged back-to-back instead of in an offset configuration (Figure 3). This makes internal valve gate nozzles ideal for high-cavitation molds or large cavities requiring side gates.

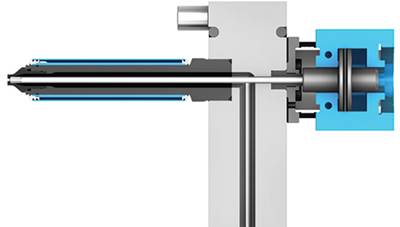

Some mold builders use large internal valve gate nozzles as melt transfer nozzles in their stack molds because a valve-gate-to-valve-gate melt transfer offers complete control of the transfer shutoff when the mold opens and closes with each cycle (Figure 4). This eliminates drool, which is a must for low-maintenance, highly automated molds.

Internal valve gate nozzles make achieving this pin-to-pin kiss-off (where the stationary and moving mold halves make contact when the mold is closed) possible, as it requires highly accurate, precision-machined nozzles that seal properly to avoid material seeping into places it shouldn’t. It also requires nozzles with extreme durability to withstand the machine clamp force, heat and melt pressure over millions of cycles.

Internal valve gate nozzles can also be used in single-nozzle systems that require only one gate, drop or point of injection. The design’s simplicity enables the nozzle to align perfectly with the machine barrel, instead of being offset to accommodate the external actuator mechanism of a traditional solution.

With these features, functions, benefits and applications in mind, mold makers may want to take a second look at the internal valve gate nozzle.

Related Content

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreRead Next

No More Cooling Required

Moldmakers and molders can increase mold uptime using today’s cooling-free valve gate actuators.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More