The holidays are approaching and MoldMaking Technology is gifting you with another monthly roundup of the new/proven products and services it has received from your favorite moldmakers and companies. December’s print focus was inspection and measurement products/services.

Also keep an eye out for MMT’s compilation of its digital-only product/service content, which showcases a comprehensive range of content, from machining, automation, hot runners and more!

Click here for November and October’s technology roundup.

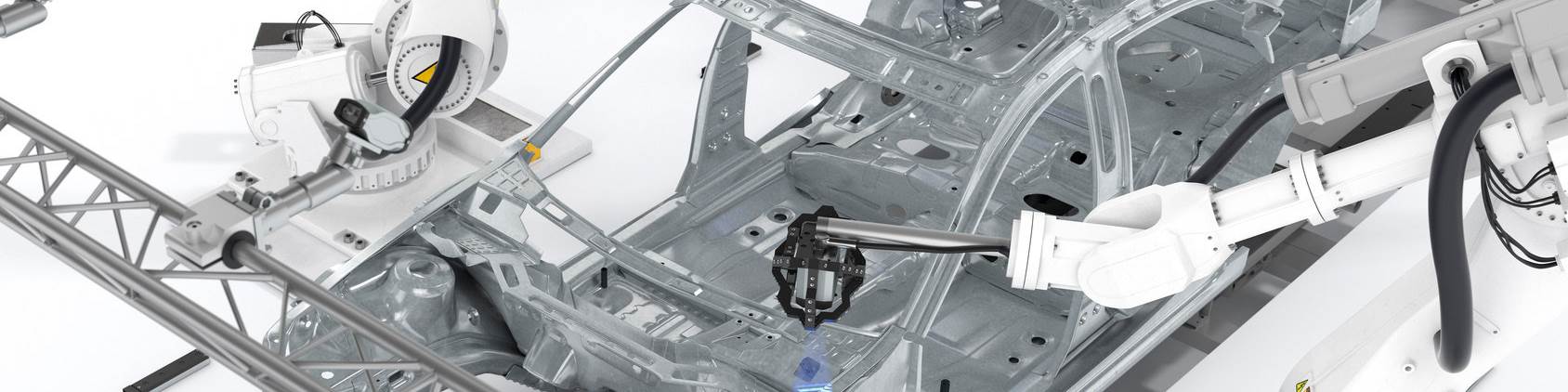

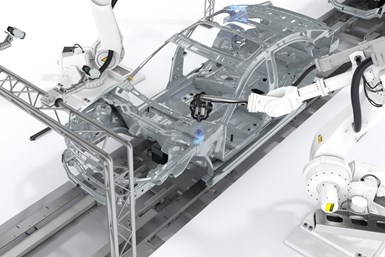

Zeiss Industrial Quality Solutions introduces its Zeiss AICell trace, a correlation-free measuring cell. A highly accurate shopfloor car body robotic process and quality control system, the cell achieves ISO 10360-8 stated accuracies while operating in extreme environments and offers what the company says is the industry's widest temperature operating range.

According to the company, the system utilizes the high-speed AIMax cloud sensor and Zeiss AICell trace robot tracking technology to accurately dimension critical features including hemmed edges, studs, rivets and nuts behind metal.

Researcher and developer for 3D digitization and additive manufacturing technologies Shining 3D adds a new line of handheld color 3D scanners, the EinScan H and HX, to its EinScan series portfolio. Both scanner lines integrate an additional light source for a broader range of applications and scanning requirements.

Renishaw Inc. outlines the advantages of its RFP fringe probe, designed for use with the REVO five-axis measurement system on coordinate measuring machines (CMMs).

The RFP probe increases the multi-sensor capability of the REVO system by adding non-contact structured light inspection to the existing product range, which now offers five different probe families, each specifically designed to maximize the advantages of five-axis motion and infinite positioning.

The L.S. Starrett Company relaunched its electronic hand tool line with the introduction of more than 100 electronic digital micrometers with new features for improved ergonomics, functionality and productivity for mold manufacture and maintenance. These electronic micrometers range from the No. 733.1 outside micrometers to a wide array of application-specific models, including a rounded anvil and tubular micrometer option that can be used to inspect mold walls and features such as hole-to-edge to verify specifications are being met.

Starrett guarantees a precise measurement at every position each and every time with its electronic micrometer offerings.

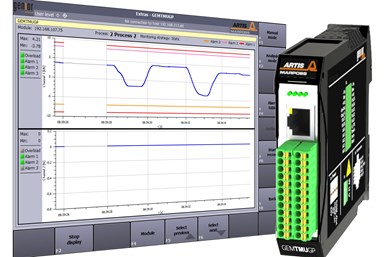

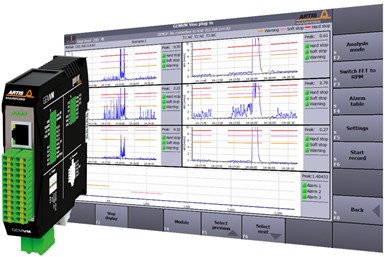

Marposs launches its Artis GEMGP stand-alone tool monitoring solution for detecting process anomalies during metal cutting in machine tools. Accommodating two sensors for measuring force and strain values obtained from the spindle during the machining process, the GEMGP is said to be able to detect and report on tool breakage, missing tools, overload, tool wear and fluid flow in real time which prevents damage to the machine, reduce scrap and improve productivity.

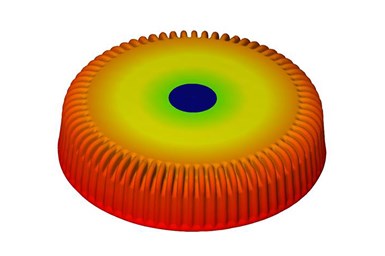

Exact Metrology performed a recent inspection on injection molded caps to showcase the capability of the GOM computed tomography (CT) scanner.

The GOM CT features a 225 kV X-ray source and a high-contrast 3k X-ray detector that generates a very fine pixel grid (3008 x 2512 pixels), laying the foundation for high-precision detection of the measured components. Five-axis kinematics with an integrated centering table make it easier for the user to position the component optimally in the measuring volume, so that the measurement is always performed with the best possible resolution.

With the ability to be integrated into Marposs’s Genior modular monitoring system, the company’s new Artis GEMVM system is said to be a highly effective solution for predictive maintenance, simple process monitoring and detection of collisions and crashes. The system monitors vibration, gravity and temperature values to detect machining anomalies, such as damage to spindle bearings or wear of the drive axles. When a sudden change occurs, the system initiates an alarm in less than 1 ms, reducing or avoiding the downtime and costs of unplanned maintenance or total failure of machine components.

3D metrology company GOM GmbH (Braunschweig, Germany) developed the digital platform, HandsOnMetrology.com for companies that want to integrate the benefits of optical 3D metrology into quality control processes. From tutorials and how-tos and personal stories and insights from makers, to a global network that connects customers to companies selling 3D scanning products, GOM offers a comprehensive hub for interested manufacturers.

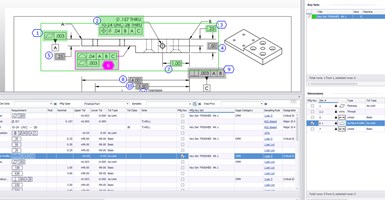

High QA, a manufacturing quality management automation software provider, releases Version 5.1 of its Inspection Manager (IM) software, which features next level Quality 4.0 standards, increased automation and enhanced workflows.

Inspection Manager is a comprehensive database-driven solution for manufacturing quality management throughout the production and supply chain process. It also delivers several enhancements to improve workflows, efficiency and traceability including in-depth AQL-based sample planning, a Manufacturing Key Sets feature, robust user access control and workflow and usability enhancements.

Takumi USA has partnered with Renishaw Inc. to be the first CNC machine tool brand to offer Renishaw’s Set and Inspect app for the Fanuc control. According to Takumi, Set and Inspect makes it possible for anyone with a part probe to add inspection probing to their process, enabling more efficiency and profitability to job shops of all sizes.

The Set and Inspect app feature is now available on the Takumi H-Series 3-axis high-speed double-column CNC machines, the Takumi V-Series 3-axis box way CNC machines and the VC-Series 3-axis heavy-duty general purpose machining centers.