Hot runners — originally invented to ensure clean sprues and reduce rejects — are playing an increasingly important role in molds to control injection molding processes. The path to this was paved by valve gate systems, which control the flow of plastic into the mold cavity using mechanical shut off pins that allow the hot runner nozzle to open and close at the tip. The ability to accurately control the flow of material through the gates enables stable processes and higher component quality with shorter cycle times, particularly in sequential and cascade injection molding.

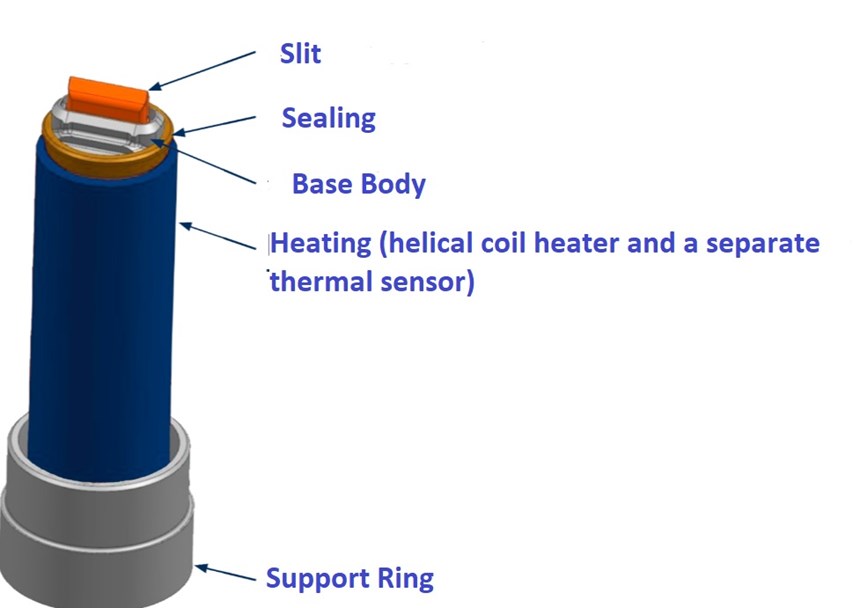

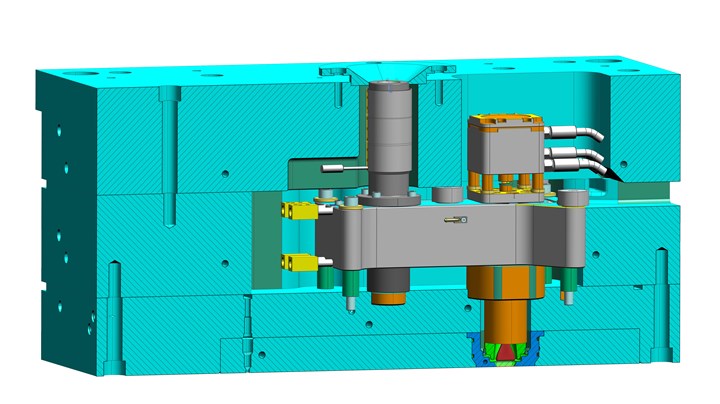

There have been numerous incremental advances in hot runners over the last years, and one of the latest is from mold builder Haidlmair Group (North American plant in Concord, Ont., Canada), which has developed an open hot runner nozzle shaped like a sheet extrusion flat die. Called the Flat Die Unit (FDU), it passes melt through a long slit (there are currently three different sizes available) instead of a circular hole like a conventional nozzle. The result is said to be faster injection of more melt through a thinner gate opening, with lower shear and injection pressure, lower melt temperature and up to 25% faster cycle time in several projects.

Haidlmair says the FDU is particularly suitable to polyolefins, including recycled material. Up to now, the FDU has been available only with Haidlmair molds. But Moulding Expo 2019 in Stuttgart, Germany, saw a newly-founded separate company, FDU Hot Runner GmbH based in Frankenthal, Germany, which is ready to supply the nozzles to other moldmakers.

“Originally, the FDU was a research project developed with the know-how of Haidlmair Group in Austria drawing on the company’s experience in extrusion flat dies for film and sheet,” Andreas Kißler, CEO of FDU Hot Runner explains. “The idea was to transfer the experience in this field to injection molding and hot runner technology to increase productivity and throughput especially for large parts, but also other applications. There was no other similar product on the market, so Haidlmair decided to develop their own hot runner system, the FDU.”

The product was presented to the public in 2016 and has been continuously developed ever since. For some time now, the system has been ready for series production and has already demonstrated its advantages in many Haidlmair tools as well as in other customers’ tools, including some from the automotive industry.

According to Kißler, the FDU is particularly suitable for the use of polyolefins. “However, recycled plastics have also been used in some projects,” Kißler says. “Due to the wide slit in which the melt flows over a triangular shape into the mold, larger particles in recycled materials can more easily pass than in conventional systems.”

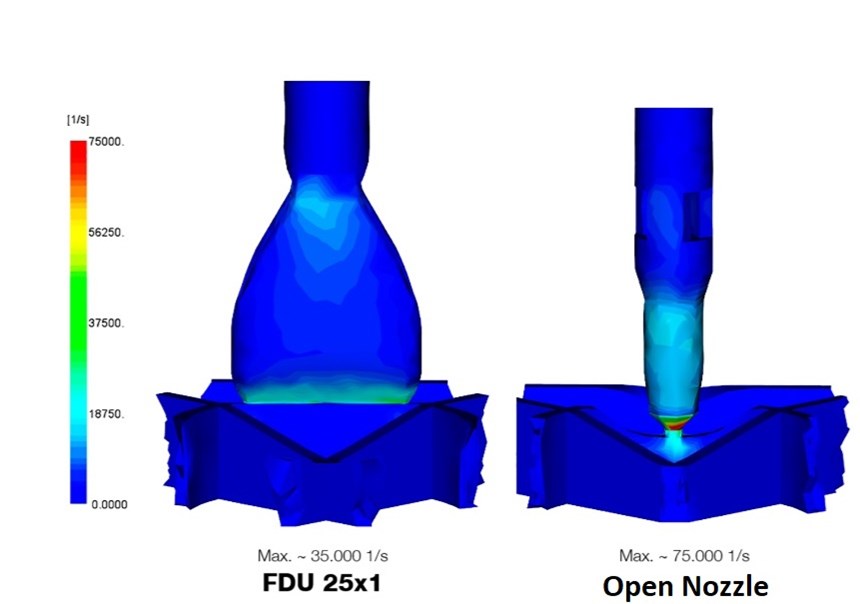

Reduced Shear Rate

The special nozzle is particularly suitable for large parts because it can handle more melt volume with less shear than conventional systems, which are round and, according to Kißler, are available with a maximum diameter of 10 mm because the heat needs to be dissipated to ensure precise temperature control of the molten plastic to avoid degradation. “To achieve the same amount of molten material flow through the nozzle, you need a 10 mm diameter in a round conventional system for a cross-sectional area of 50 mm². We realize the same cross-sectional area with a slit of 25 by 2 mm. The advantage is that we are only 1 mm away from the cooling cavity wall, while the center of the round nozzle is 5 mm away, which limits the design in terms of size to realize adequate cooling.”

Nozzle sizing is important for maintaining sufficient molten material flow or injection rates, especially for molding parts with low wall thickness or unfavorable flow distance/wall thickness relation. “We simulated the molding of a popcorn cup, for instance, which exhibited a flow distance of 285 mm and 0.75 mm wall thickness, which according to the Moldflow software simulation was not possible using conventional open round nozzles. Our system managed to keep the required injection rate into the cavity because of the higher volume flow rate.”

Since the shear rate of the material — which is important because small variations will cause a large shift in the viscosity — is proportional to the injection speed, the injection speed is limited by the size of the nozzle. If the material is subjected to large amounts of shear forces during the cavity filling stage due to high injection speed, this will make the mold filling inconsistent, resulting in shot to shot inconsistency. The larger cross-sectional area of the FDU allows for reduced injection pressures and higher injection speeds, reducing cycle times, Kißler explains.

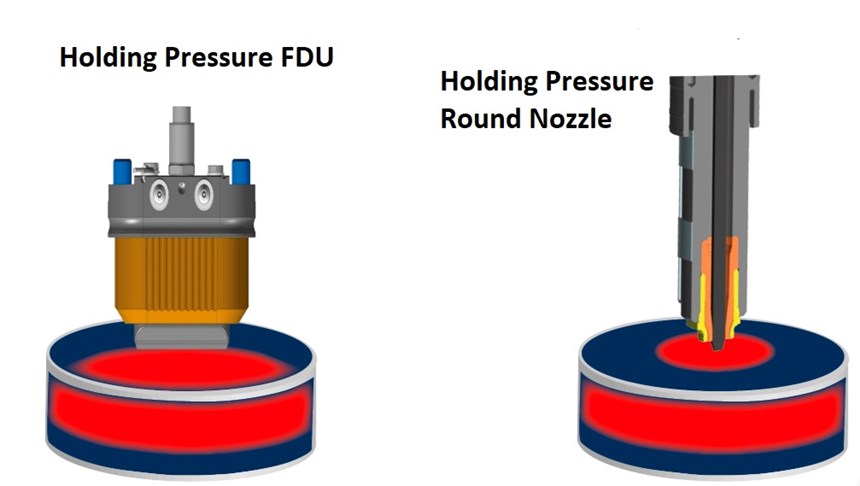

Optimized Holding Pressure

In order to increase the density of plastic to compensate for the shrinkage after the mold cavity has been filled with plastic, pressure holding is necessary to continue to exert pressure to the melt plastic. “In the holding process, the plastic flow rate is very low, so the flow is no longer a leading role here; pressure is a main factor affecting the packing process,” Kißler says. “In the holding period, due to the high pressure, the plastic part can be found to be compressed locally. In the area of high pressure, the plastic is more compact, so the density is higher. While the pressure is lower for some other places, the plastic is loose and the density is lower. So, the density distribution changes with position and time. Our special design of our flat die unit ensures a more even pressure distribution.”

Another advantage of the FDU’s design is said to be the avoidance of free jet formation at the gate (“sausage injection molding”), which occurs with rising injection speed and results in non-uniform mold filling and surface faults. If assistance cannot be provided here by suitable mold design, the machine must be operated at a low injection speed.

FDU vs. Conventional Open Round Nozzles

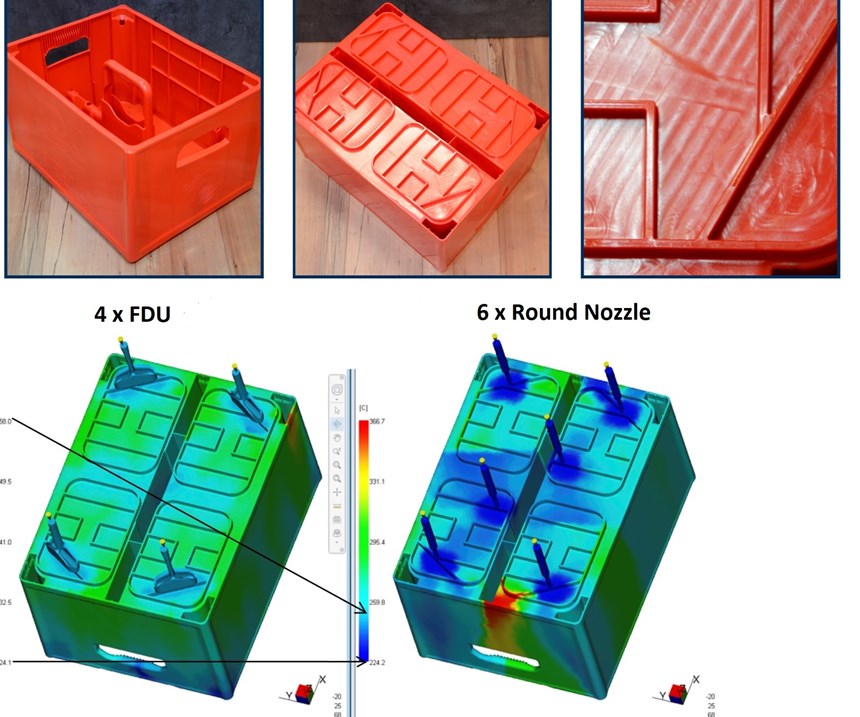

Kißler describes several comparisons of molding parts with the FDU vs. conventional open round nozzles.

In one case, an FDU 58 mm long by 0.5 mm wide provided 5.9 times the flow volume of a 2.5 mm round nozzle with approximately equal shear rate. Because the FDU gate is only 0.5 mm wide, it allows for faster gate freeze than the round nozzle. In another case, one FDU molded a 500 g polypropylene (PP) part with the same fill rate and shear rate as two 2.5 mm round nozzles, but at 5-10% lower cycle time.

Kißler claims that the lower shear provides less stress on the melt and more uniform fill temperature than conventional nozzles. An example is shown in figure XX (tbd), showing an injection-molded toolbox, illustrating the more uniform fill temperature distribution and, as a result, a 25% cycle time reduction.

Another example involves the manufacture of a box for meat transportation, where the FDU molded the part with a 17% reduced cycle time compared to a valve gate system and a 200-bar reduced pressure. In another case, a pallet made from PP (MFI 15g/10min) was injection molded with an FDU with an injection pressure of 700 bar (specific), injection time was 3.6 seconds, holding pressure 5 seconds, resulting in a claimed cycle time reduction from 58 to 42 seconds.

Related Content

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

Putting Recycled Plastics to Work

Haidlmair discovered that if recycling is done correctly, the difference between virgin and recycled plastic material is minimal.

Read MoreHow to Offer Employees More Than a Normal Job

Austrian moldmaker Haidlmair focuses on its 550 people in a very unconventional way, as it continues to be a leading specialist in building high-quality tools for beverage crates, folding boxes, and garbage containers.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=150;quality=70)

.jpg;maxWidth=400;quality=70)