Soft Wired: Cutting High Taper Angles with Wire EDM

Examine the wire’s properties to determine the right one for achieving the best cut.

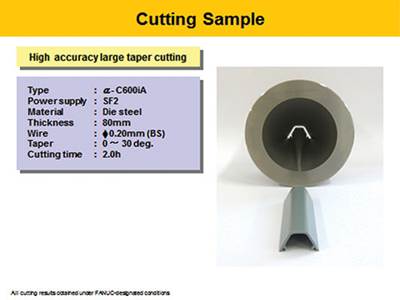

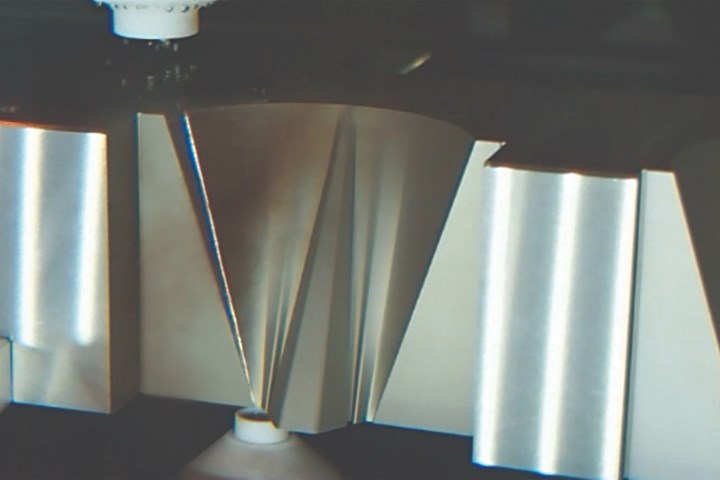

This injection mold was machined on a wire EDM using soft brass wire and tapering up to 30 degrees. The machine uses optional large-opening flush nozzles that prevent the wire from curling over the opening of the nozzle during the machining of the large taper sections.

When conventional machining processes cannot successfully cut high taper angles, wire EDM can. However, mold manufacturers using wire EDM technology face some challenges when cutting such angles, which can range from 10 to 45 degrees. Oftentimes, EDM machines have the axis movement necessary to achieve the desired angle, but the physical properties of the wire and related machine technology may not be adequate. Examining the wire’s properties is useful in determining the right wire for achieving the best cut.

Hard vs. Soft Wire

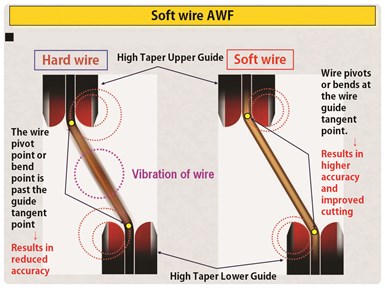

Hard wire is stronger, straighter and more resistant to breakage during cutting than soft wire. High-tensile strength, harder wire can also better fight deflection during cutting, but very hard wire with little elongation can cause vibrations during taper cutting as the wire travels between the upper and lower wire guides. In addition, hard wire’s “memory” resists the true programmed wire path during high-taper cutting, which bends the wire and can lead to reduced accuracy, poor surface finish or wire breakage. This will leave intolerable marks on the workpiece and waste material and production time.

A better solution for cutting high tapers is soft wire. Low-tensile strength, soft wire easily bends to follow the correct path determined by the CNC controller and provide more accurate cuts. However, soft wire has less memory than hard wire and is prone to breakage in aggressive cutting conditions. It is also sensitive to the voltages and tension applied to it by the EDM machine during the AWF cutting cycle. If not handled properly, the result is a malformed wire tip that is curved and prevents the wire from being able to be inserted into the wire guides. In these instances, the machine is unable to thread or re-thread the wire, so the erosion process is stopped and production time is lost. The operator is required to manually intervene before cutting can begin again.

Overcoming Obstacles

To overcome the challenges of soft-wire threading, consider EDM equipment that provides improved wire processing during the AWF cutting cycle. Technology should include a way to precisely control the wire tension and energy used to cut the wire.

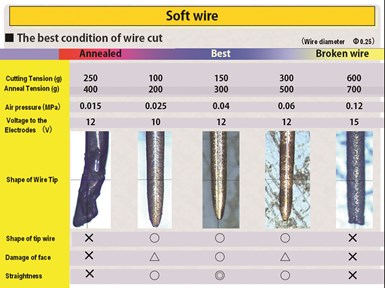

The ideal AWF situation is one where the wire heats and stretches until it breaks in two without melting. Using the ideal voltage needed to cut the wire and form a bullet point can enhance soft wire threading performance, improving the straightness of the wire and decreasing electrode wear (see Figure 1).

Figure 2.

It is not just the hardness or softness of the wire that needs to be considered, however. Factors such as wire diameter, cutting and anneal tension, and voltage need to be fine-tuned based on the wire selection in order to preserve the shape of the wire tip, minimize damage to the face and maximize straightness (see Figure 2).

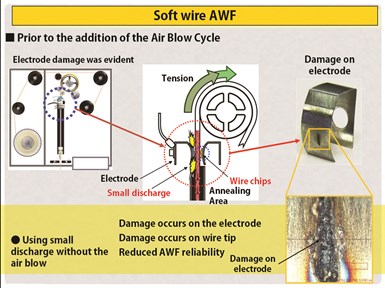

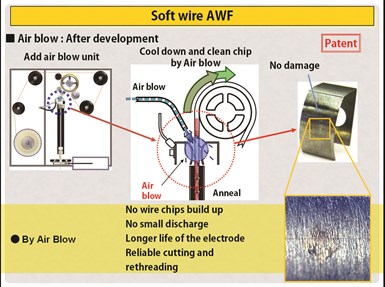

The small discharges used in wire EDM can result in electrode and wire tip damage, wire chip buildup and reduced AWF reliability (see Figure 3). Some EDM machines offer an air blow system that directs cool air to the wire cut point. This keeps the wire tip as cool as possible and also prevents a molten tip from being produced during thermal wire cutting.

To optimize the threading cutting cycle, a relay on a timer is used to open an air solenoid to gently blow cool air onto the wire cutting electrode and keep the wire tip from heating up to a melting stage. This prohibits wire chip buildup, extends electrode life and provides reliable threading and cutting performance (see Figure 4).

During the cutting phase, accurately controlling wire tension is critical (especially with soft wire), so an AWF system with a wire tension monitoring device that provides continuous observation is important. EDM systems that include an AC motor and encoder wire drive system working in tandem enable the tension motor and drive roller to communicate energy usage to the controller, and will allow the operator to better maintain wire tension throughout the cutting process.

There are also some measures the operator can take to improve cutting performance. When working with soft wire, it’s important to use a die guide designed for large-taper cutting, especially if you are going to skim-cut the large tapers to improve surface finish and accuracy. These guides have a much larger support to help the wire transition through large angles.

To ensure accuracy, also use the features in the CNC that compensate for the changing position in Z-axis direction so that the taper angles are precise. Finally, if the cutting technology being used was developed for hard brass wire, the wire tension will have to be reduced on the rough cut.

Opportunities and Applications

Technology developments in EDM have affected machining across many industries. The ability to accurately and efficiently machine taper cuts using soft wire has opened up new areas of opportunity for the technology. For instance, mold manufacturing regularly requires parts with steep angles. Mold builders depend on the accuracy of the angle to ensure proper location and alignment of components in the mold. The more accurate and smooth the finish, the less additional, time-consuming, manual fitment and polishing is required by the moldmaker.

Another benefit of wire EDM in moldmaking is the ability to quickly manufacture prototype molds. This identifies problems that may occur during actual production and helps to prove out the efficiencies of the tooling and the viability of the part prior to building costly hard tooling, saving time, money and frustration.

Mold manufacturers who want to take advantage of today’s EDM technologies and strategies need to consider their wire options as well as appropriate EDM equipment features.

Related Content

Machine Monitoring Platform Improves Machine Utilization, On-Time Delivery

Using data from a machine monitoring platform, Westminster Tool added almost 75 hours of capacity per week by shortening warmups and starting CNC and EDM machines sooner.

Read More2024 Moldmaking Insights: A Year in Review Part 2

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

Read MoreFive-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

Read MoreCollaborative Engineering Drives Quality Mold Solutions

Advanced engineering and tooling teams collaborate to train, design, develop and deliver high-quality, cost-effective molds efficiently, ensuring perfect parts and faster launches.

Read MoreRead Next

Soft Wire Threading for Wire EDM’ing: Tips for Success

Look for EDM equipment that provides improved wire processing during the AWF cycle. Technology should include a way to precisely control the wire tension and energy used to cut the wire.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More